Features

Introducing the KCP-E Series with World-First and Industry-First Advanced Technology Built-in.

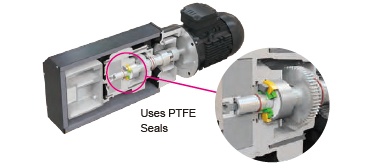

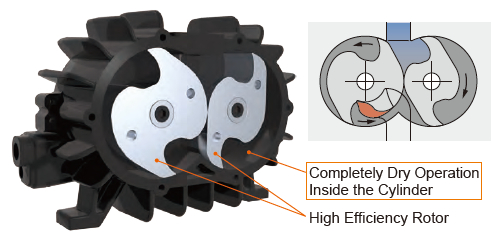

Our newly developed vaneless, no-contact rotor gives vacuum power using less energy. And of course it's oil-free! Plus, no-contact means even lower noise. Large reduction of harsh low frequency noise (especially 300 Hz and below.)

Using digital analysis technology, we have achieved the optimum curve of our newly developed, high efficiency (non-contact) rotor.

Vacuum pumps create a vacuum by sweeping moving) air out from a particular space. Thanks to our non-contact cylinder construction, the newly developed high efficiency rotor achieves low energy losses. And because the pump is oil-free, it provides economical clean air. In addition, an improved level of maintenance can also be realized.

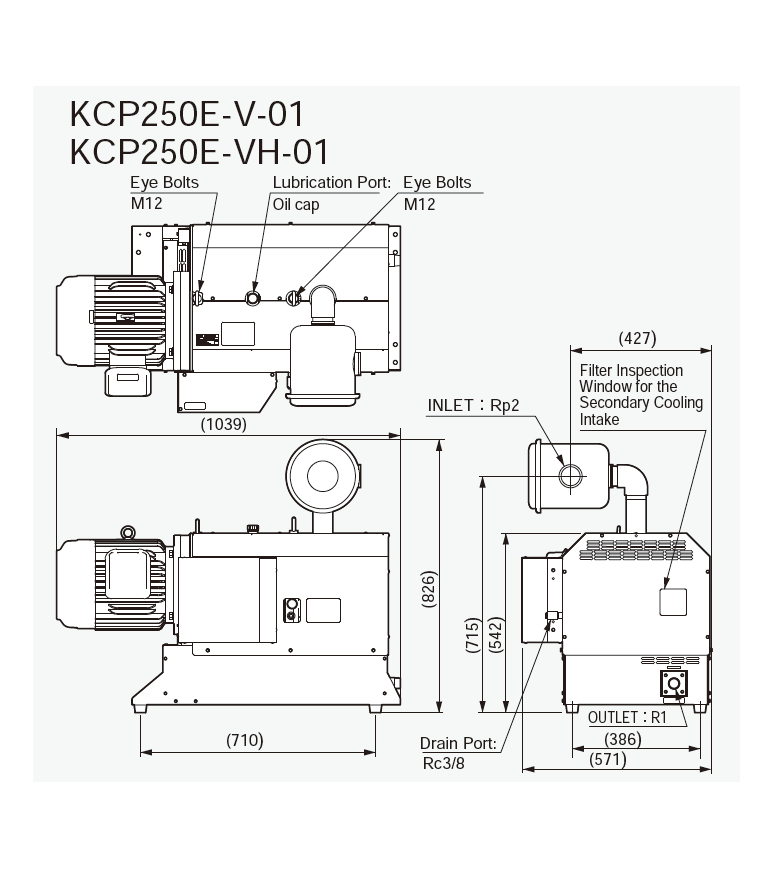

With ORION's original temperature reduction technology, we are the first to achievecontinuous attainable operation of a 5.5 kW class motor.

A cutting-edge, innovative vacuum pump with three original built-in technologies.

The heat-load problem which was an obstacle to continuous attainable operation was solved by ORION's original temperature reduction technology. And we succeeded in achieving the world's first continuous attainable operation with a single-stage claw vacuum pump of the same class.

| Forced Local Cooling | Temperature is significantly reduced by forcibly blowing air near the pump exhaust port, which is the area that generates the greatest amount of heat. |

|---|---|

| Heat-Transfer Reduction Construction | Propagation of heat from the pump cylinder to the gearbox is reduced. |

| Secondary Air Intake | Negative pressure inside the cylinder is used to introduce outside air and cool the pump without increasing power consumption |

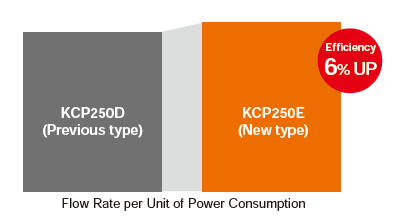

Our high efficiency twin rotor gives a high flow rate using less power.

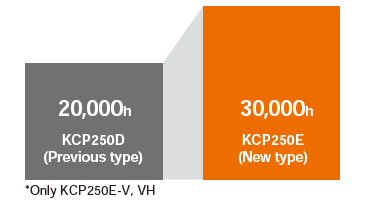

Lower internal loading for a longer product lifespan.