Types of Supply Water

Generally, water supplied to the humidification unit is deionized water or pure water.

If supplying the humidification unit with water that meets the standard for tap water under the Waterworks Law, there will be small amounts of dissolved mineral components (calcium, magnesium, chlorine, etc.) included with the humidification (water steam), which can result in problems due to sticky scaling deposits. Scaling is the solidified evaporated residue resulting from silica (SiO2) and hardness components (calcium and magnesium) etc. contained in the supply water that precipitate out and crystallize once the solubility limit of the water has been reached. Scaling that has precipitated out will not dissolve back into the water and will instead accumulate on the bottom of the drain pan, resulting in various impediments, and the nozzle misting will result in white powder-like substance to precipitate and be suspended in the air. If water other than tap water is used for cooling water in a water-cooled precision air processor, that water must meet the water quality standard (JRA-GL 02:1994) established by the Japan Refrigeration and Air Conditioning Industry Association. (Details are written on the specifications sheet.)

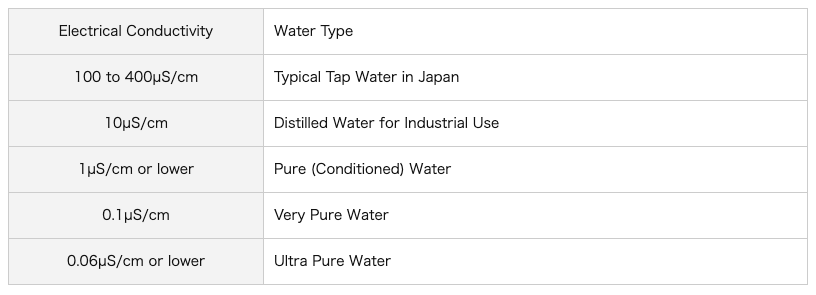

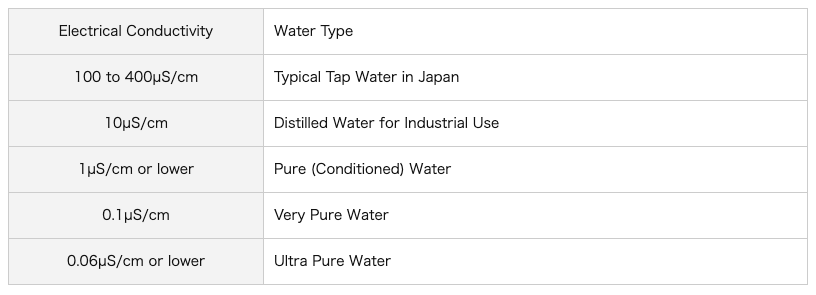

Types of Water and Electrical Conductivity

Tap water which supplies homes and factories is processed at water processing plants. However tap water contains trace amounts of positive ions including calcium and magnesium, as well as negative ions such as chlorine or nitric acid, etc. These ions can act as impurities and have an adverse affect when used for cleaning or analysis. Water that does not contain these impurities is "pure" water. Pure water literally means "water free from impurities" by means of a process such as filtration, distillation, centrifugation, ion-exchange or solvent extraction, etc., to remove suspended matter or impurities. It is used to clean flasks, beakers, or other experimental tools, as well as to adjust the concentration of reagents.

Ultra pure water is high purity water that is virtually free from metal ions, microbes, or other impurities, approaching theoretically 100% "pure H2O", and is used in VLSI semiconductor manufacturing processes in order to wash wafers, etc., and in pharmaceutical manufacturing and other related processes. On the one hand, ultra pure water is free from impurities, but on the other hand, impurities (such as organic matter, fine particulate, metal ions, etc.) are easily dissolved in it, and therefore it goes by another name, "hungry water".If metal piping and fixtures are exposed to this ultra pure water for long periods of time, leaching and corrosion of alloy components in such piping can result.

Under the International System of Units (SI), the unit for electrical conductivity is S/m (Siemens per meter), however when referring to water purity, S/cm is currently still widely used.

1 S/m = 0.01 S/cm = 10 mS/cm, 1 µS/cm = 100 µS/m = 0.1 mS/m

Water types based on electrical conductivity are shown in the chart below.

※ The water used as a supply for humidification water should have an electrical conductivity in the range of 1 to 10 µS/cm.