Features

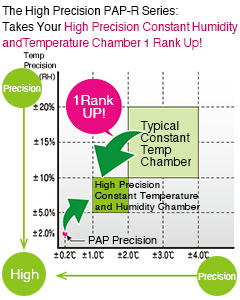

The PAP-R Series: Offering One Rank Up in High Precision Air Processing

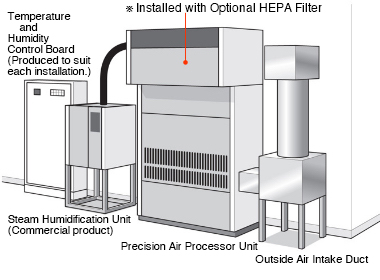

Integrated Design Saves Space and Eases Installation

Convenient All-In-One Design

Previous Air ProcessorsEach component takes up valuable space.

Previous Air ProcessorsEach component takes up valuable space. PAP-R Facility-Use Precision Air ProcessorAll-in-one design saves space

PAP-R Facility-Use Precision Air ProcessorAll-in-one design saves space

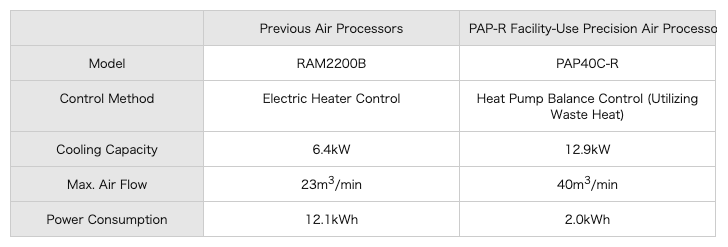

Energy Saving Example

Power Consumption Comparison of Precision Air Processors for Constant Temperature Chamber, Constant Temperature and Humidity Chamber, Clean Room

Optional Equipment

Optional Equipment and Parts

For Precision Air Processing Applications in Every Field

ORION has many items in addition to the optional equipment shown below to suit our users' environment, needs, and demands. Please feel free to contact your dealer with any questions.

Plenum Chamber With HEPA Filter

Plenum Chamber With HEPA Filter Plenum Chamber

Plenum Chamber Rear Intake Unit

Rear Intake Unit Outdoor Unit Wind Shield

Outdoor Unit Wind Shield Drain-Up Unit

Drain-Up Unit Elevated Base

Elevated Base Front Intake Noise Reduction Chamber

Front Intake Noise Reduction Chamber Communications Software

Communications Software

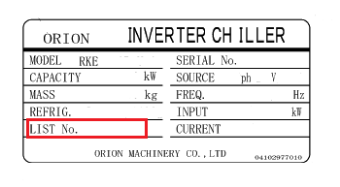

<Part Name>

・Plenum Chamber with HEPA Filter Assembly

・Plenum Chamber Assembly

・Rear Intake Unit Assembly

・Front Intake Noise Reduction Chamber Assembly

・OA Set Assembly

・Outdoor Wind Shield Assembly

・Drain-Up Unit (Incl. PVC Piping Kit)

・Elevated Base

・Sensor Mounting Bracket Assembly

・Humidification Unit Water Supply and Drainage Coupling Set (For PAP20A-KR and PAP40C-KR models)

・Condensation Piping Set

・Base Cover Plate Set

・Remote Control Cord Assembly (50 m)

・Remote Control Cord Assembly (100 m)

・Communications Software Set

Applications

Application Examples

・Cleanroom (Pharmaceutical, Cosmetic Production Etc.)

・Precision Measurement Room (3-D Measurement Instruments, Tensile Testing Equipment, Laser Measurement Instruments, etc.)

・Precision Processing Room (Nano Processing Equipment, Electrical Discharge Machines, etc.)

・Storage of all kinds of Materials...etc.

・Plant Cultivation Room / Plant Factory...etc.

Every kind of system that meets our users demands.

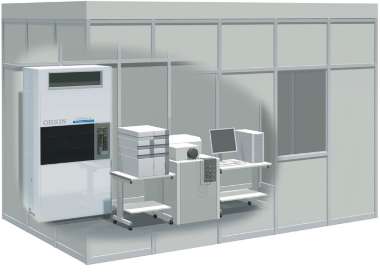

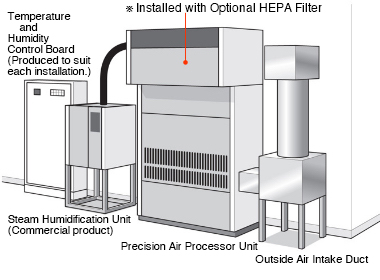

System Installation Examples

① Outlet Control Method (±0.2 to 1 ℃)

② Intake Control Method (±0.5 to 2 ℃)

Installation Examples

Constant Temperature and Humidity Chamber [Set Temp/Humidity: 23 ℃/50% year-round control]

Built-in design (fitted inside insulation panels) makes the air processor flush with the wall, providing an effective use of space.

Specifications

*1 The temperature and humidity control range noted does not necessarily indicate the actual controllable range possible.

The range of control depends on the condition of the air supplied at the intake.

*2 When the intake air temperature and humidity, and outdoor ambient temperature are stable. Noted precision is based

on measurement by the internal controller at a single air outlet point.

*3 When operating according to JIS B 8616.The displayed performance will be at least 80% when the intake air

temperature of the outdoor unit is at least 35 ̊C.

*4 When operating according to JIS B 8616.The displayed performance will be at least 75 % when the intake air

temperature of the indoor unit is below 20 ̊C. The compressor will stop, and exclusive operation of the auxiliary heater

may occur if the control air intake temperature drops to approx. 15 ̊C or lower.

*5 The noted external static pressure is when the controlled air is regulated at the outlet to produce the maximum rated

processing air flow.

*6 External dimensions do not include miscellaneous protrusions such as eyebolts, etc.

*6 Maximum value within the range of unit specifications. Starting current is equal to or less than the operating current.

*7 The figure noted is when the equipment is operating at the highest level of humidification operating at the highest

capacity of its normal operating range.

*8 Source voltage phase unbalance should be less than ±3%.

*9 Maximum value within the range of product specifications.

*10 The figure noted is when the product is operating at the highest capacity of its normal operating range.

*11 Measured value (A scale) when operating at the rated processing air flow, at a position of non-resonance, 1 m from

the front face of the indoor unit, and at 1 m from the front face of the outdoor unit, at a height of 1.5 m.

*12 Blower fan output cannot be increased.

*13 Use the measured temperature and humidity bias function to correct any error between the temperature and humidity

shown on the control panel and the user's measured temperature and humidity.

Note 1: This product does not detect electrical shorts and does not have a protection function against them. An earth

leakage breaker must be installed on the primary side of the power supply.

Note 2: All ducting should be insulated and ducting length should be kept as short as possible. (5 m or shorter

recommended.)