Features

What is a Coolant Chiller?

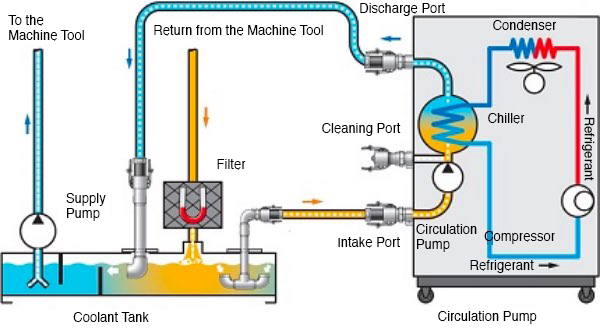

Temperature regulation equipment for water-soluble coolants (cutting and grinding fluids) used in machine tools such as machine centers (MC), NC lathes, and NC grinding machines that are used to machine metals, plastics, ceramics, and other materials.

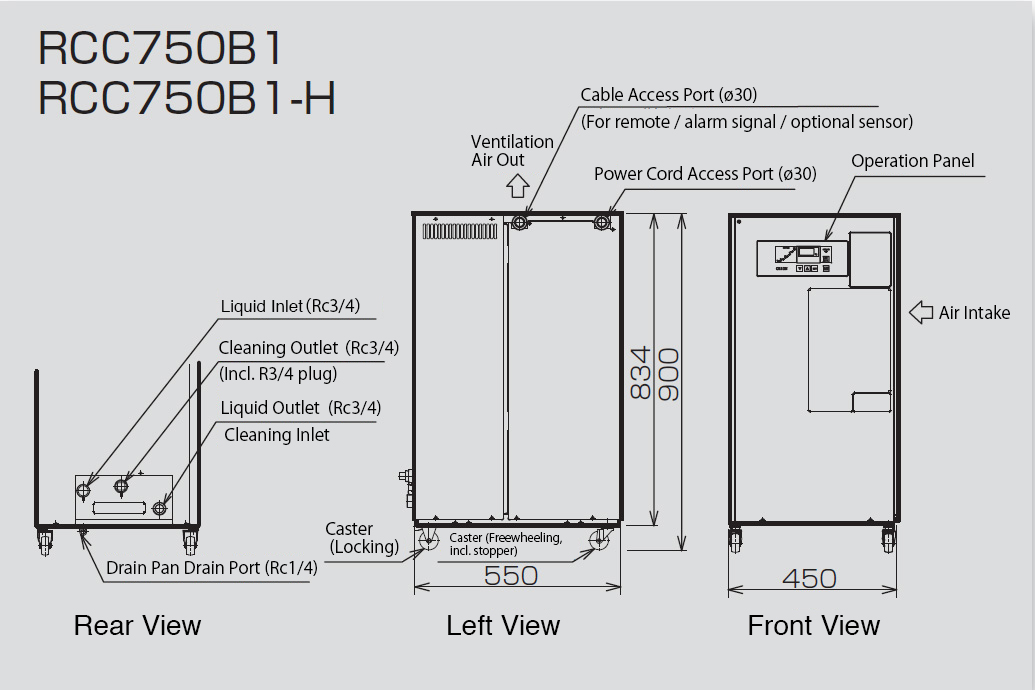

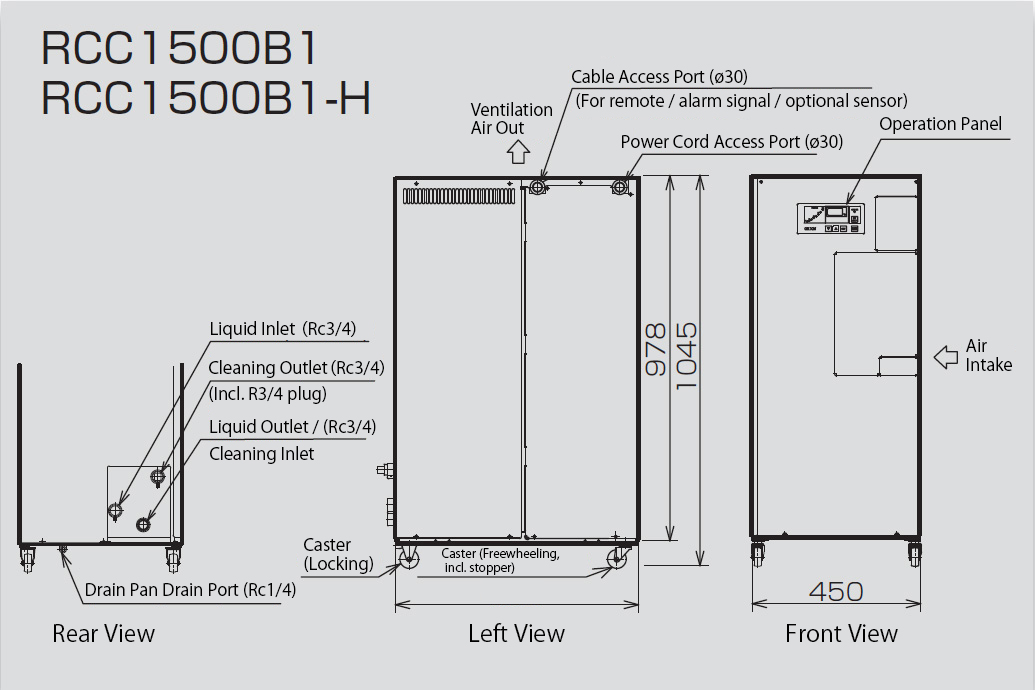

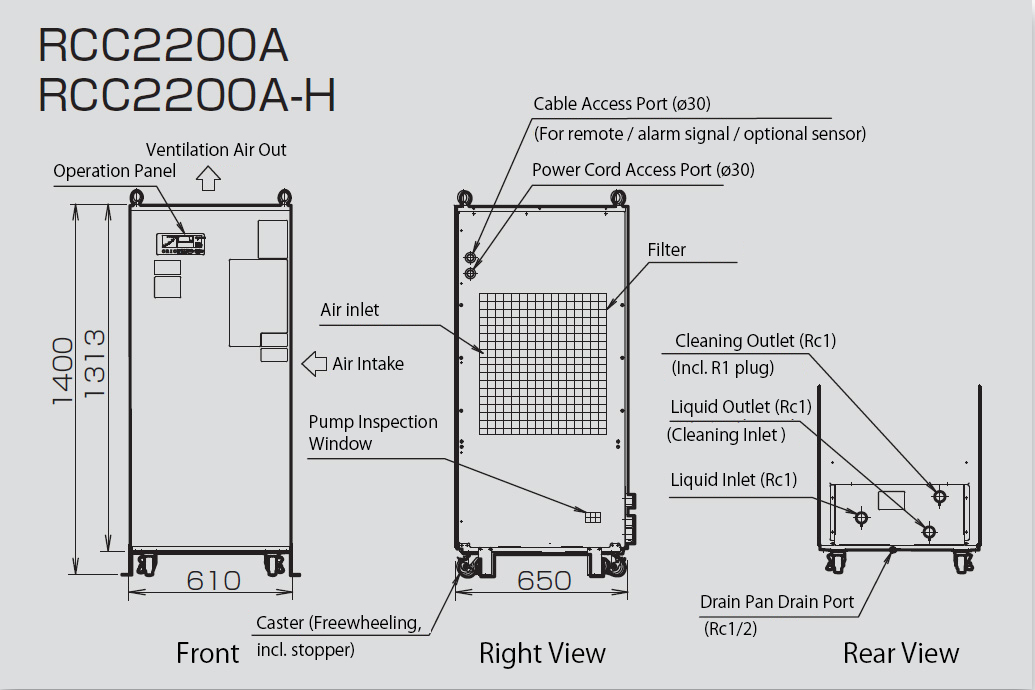

Circulating type allows for easy setup even with shallow tanks.

Can be used with shallow tanks. Easy to add on to existing installations. Previous immersion type units required deep tanks. Our piping option allows for even easier installation.

Energy Saving from DC Inverter Control

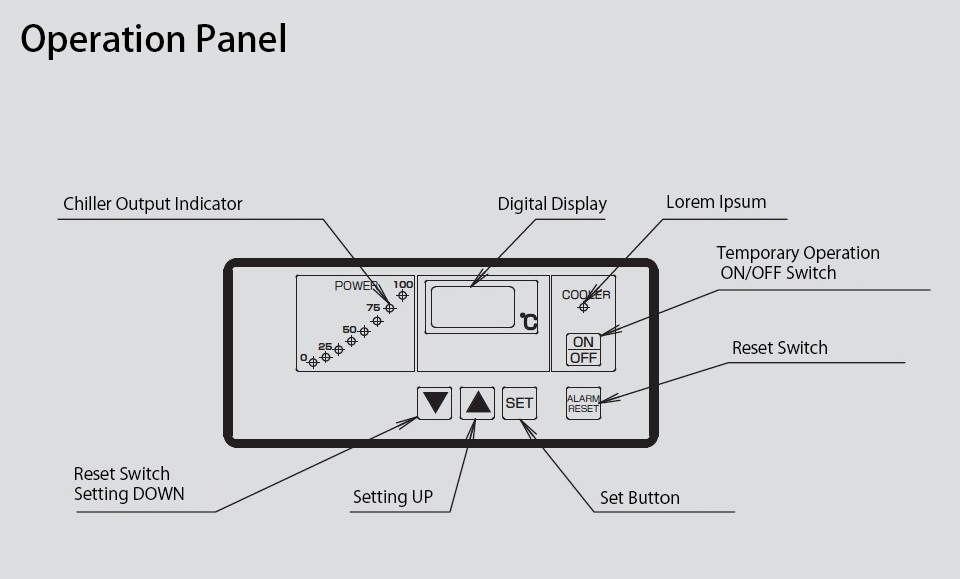

Control is simple with ORION's special digital electronic temperature controller. Temperature settings, measured temperature, and error codes are shown on the digital display.In the off chance that trouble occurs, the displayed error code informs you of the operating state at a glance. DC inverter control offers wide ranging energy savings compared with older models that use HB (hot gas bypass) or ON-OFF control. In addition, the indicator display gives an intuitive and easy to see indication of the operating rate (load factor).

Easy Temperature Setting with ▼▲ Keys

Differential temperature control operation functionality is built in.Easy switching is possible by installing the optional machine temperature sensor, and changing parameter settings.

Includes remote operation terminals and also combined alarm output terminals.Easy to operate along with your machine tool.

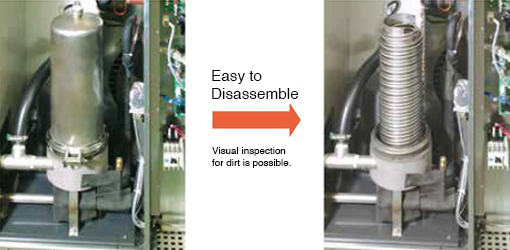

Built for Easy Evaporator Disassembly and Cleaning

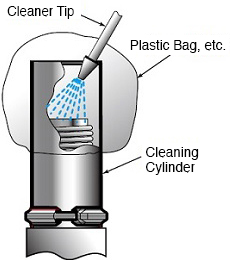

Easy to disassemble. Cleaning of the evaporator is made easier using the special cleaning cylinder. The piping system has a cleaning port to allow for simple backwashing. The control panel shows when the evaporator is dirty. "C45" on the display means you it's time to clean.

Cleaning is simple using the cleaning cylinder and a high pressure cleaner.

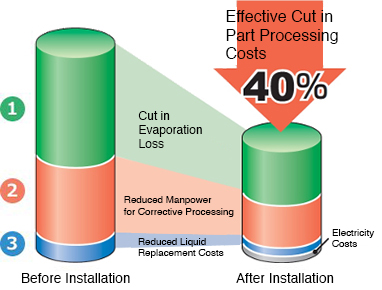

Operating Effectiveness

❶Coolant evaporation loss is cut in half, effectively saving manpower to replenish liquid.

❷Effectively saves manpower that would be used in correction processing.

❸Reduces coolant degradation and odor for longer liquid replacement cycles and lower coolant expenditures.

* According to our company calculations of reductions in coolant-related expenses associated with machining.