Chiller that continuously supplies cold water

We can use a refrigerator to cool water. But a refrigerator won't provide you with a constant supply of cold water. For a constant supply of cold water, you need a chiller.

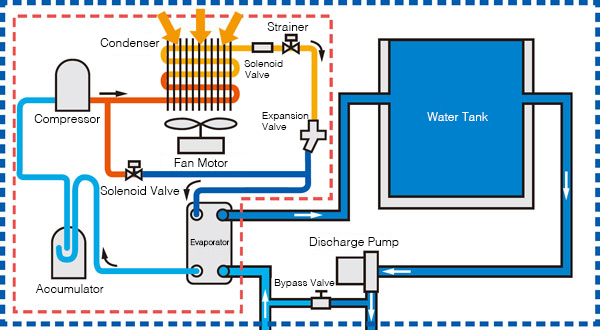

Water in a chiller is circulated through an evaporator in order to provide a sustained supply of cold water. Chillers are used to cool hot areas on devices such as laser processing equipment or high-frequency heaters, and are also suitable for cooling to a fixed temperature when needed. For these reasons, chillers are widely used.

The basic chiller is only a refrigeration unit whose main role is cooling. In addition to this main unit, other components such as water tanks and pumps, etc must be chosen and installed, and the system that controls these components must also be designed and manufactured.

In addition to layout design, and on-site piping and wiring must also be carried out. However, ORION's chillers with built-in water tanks have the cooling components, water tank, and pump in a single unit, so all that is needed to start operating is piping to and from the user's equipment and some electrical hookups.

The red outline in the illustration below shows a basic chlorination chillers with built-in water tanks are an all-in-one solution.

Solving Problems by Introducing a Chiller (Welding Machine Application Example)

Proper chiller setup can resolve many problems in manufacturing quality and lower running costs. As an example, we will look at problems associated with a welding machine and how the introduction of a chiller can resolve these problems.

Problem 1: Summertime Condensation Formation

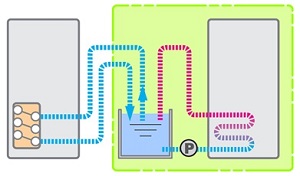

When cooling using groundwater, condensation will form due to the temperature difference, and this condensation can damage the welding machine. By using a chiller, water temperature can be stabilized and cooling can be achieved without condensation.

Problem 2: Insufficient Summertime Cooling

When using a radiator to cool surrounding air without any type of refrigeration, weld quality and electrode tip lifespan can both be reduced due to insufficient cooling during extreme temperature rises during hot summer periods. Using a chiller, stable temperatures can be achieved even during summer months, and of course, tip-dressing frequency can be reduced and tip lifespan can be improved.

Problem 3: Drop in Welder Performance

When a cooling using a cooling tower, worsening water quality can cause the inside of electrodes to become dirty, resulting in a drop in welder performance. On the other hand, chiller-based cooling is a closed circuit, which reduces water-quality degradation. Also, since operation can be synchronized with the target equipment, troublesome valve operation before and after each use is unnecessary.

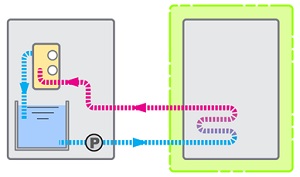

Problem 4: Wasted Tap-Water

Cooling by using a constant stream of tap water will incur extremely high running costs. Setting up a chiller can reduce running costs.

For example, if a chiller is used under the following conditions -- cost of tap water: ¥500/m3; cost of electricity: ¥15/kW; chiller water replaced twice per month; running time: 5 h/day, 300 days/year; flow rate: 3.0 L/min -- the cost reduction over using tap water would be 80%.

Chillers are Used in Many Applications Like These

MRI Cooling

MRI scanners that have built-in helium compressors use chillers to cool the helium gas. The MRI scanner cannot be switched off even when not being used for an examination, so the chiller must operate continuously. For this reason, the effective energy savings offered by an inverter chiller is very beneficial.

Die Temperature Control for Molding Machines

In addition to P.E.T. bottle caps, tableware products such as plastic bowls and plates are produced by processes such as flowing resin into a mold, heating and compressing, and curing, which are carried out by molding machines and related equipment. By cooling the molds with cold water supplied from a chiller, plastic can be cured in a short time and takt times can be improved.

Reflow Oven (Reflow Soldering Equipment)

Printed circuit boards that undergo soldering processes see a lot of heat stress, so a big issue is how to reduce the resulting thermals stress on surface mount devices. An air-cooled heat exchanger (condenser) is set up inside the tank, and cold water from a chiller is circulated through the heat exchanger. The temperature inside of the tank is kept constant via contact with a stream of fan-blown cooling air. The cooling part may be installed at the very end of the oven and/or at the reflow area.

Other Application Examples

ORION Machinery chillers and unit coolers are used in many different fields. Please check out our Chiller Application Examples page for details.

ORION Reliability & One Stop Service

Through our total coverage of design, sales and service for each of our customers, we respond to all of our customers' needs from energy saving proposals before introducing equipment, to post-installation maintenance.

ORION Machinery has networks in each industry, and utilizing the know-how we have cultivated from those industries, we offer careful service from the moment we receive an inquiry.

* ORION One-Stop-Service provides consistent support for everything from detailed proposals before introducing new equipment to testing and maintenance.

One Month Inspection Visit

We will check operating conditions and offer a proposal on how to achieve optimal performance.

* Note that the travel cost is not included in this service.

* Note that this service may not be available for some models or under some conditions.

Fee-Based Fixed Term Inspection/Maintenance

We will respond quickly via our nation-wide service network. Our ORION authorized technician has detailed knowledge, and will handle inspection, installation, and tuning of all important areas.

* Note that this service may not be available for some models or under some conditions.

Energy Saving Proposal

We will present various optimized chiller-based proposals, including energy saving proposals for current facilities, proposals to change away from city water, and proposals better maintain water temperature and water quality by changing away from water towers.

Best Match Proposal

We will offer a "best match" equipment proposal based on a detailed survey of our customer's situation and needs.

Product Demonstration

Feel free to contact us and ask for an available evaluation unit.

Post-Delivery Test Run Confirmation

In order to ensure optimal operation, we can visit your facility and offer advice about the working environment and operating conditions.

* Note that this is a fee-based service.

* Note that this service may not be available for some models or under some conditions.