Features

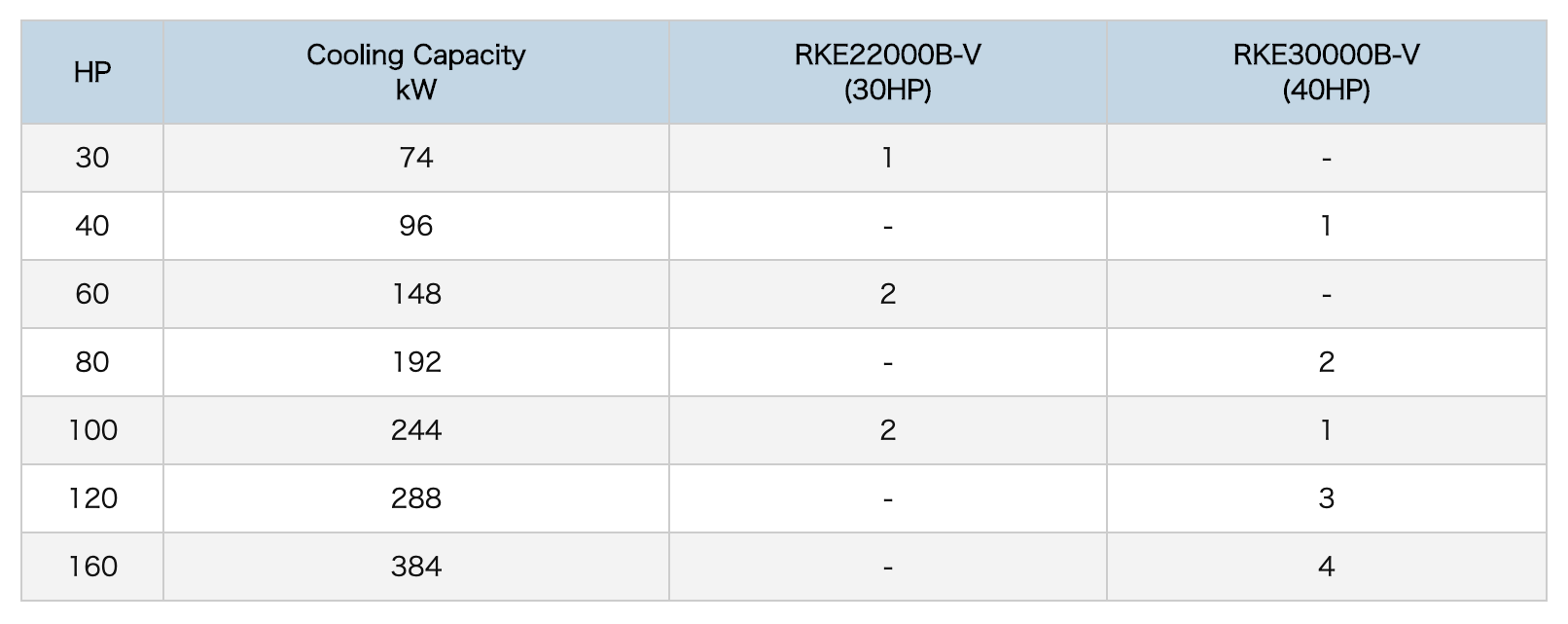

Units can be Linked for Max. 384 kW

Units can be linked together for heavy-load cooling facilities. Up to 4 units can be linked together so you can choose a capacity level to meet your demands.

Energy Saving

Reduced Energy Consumption Thanks to our DC inverter Drive Compressor

Low Operating Noise

Operating noise of just 65 dB with our low-noise fan and compressor-noise-prevention cover.

Pump is also Inverter Driven

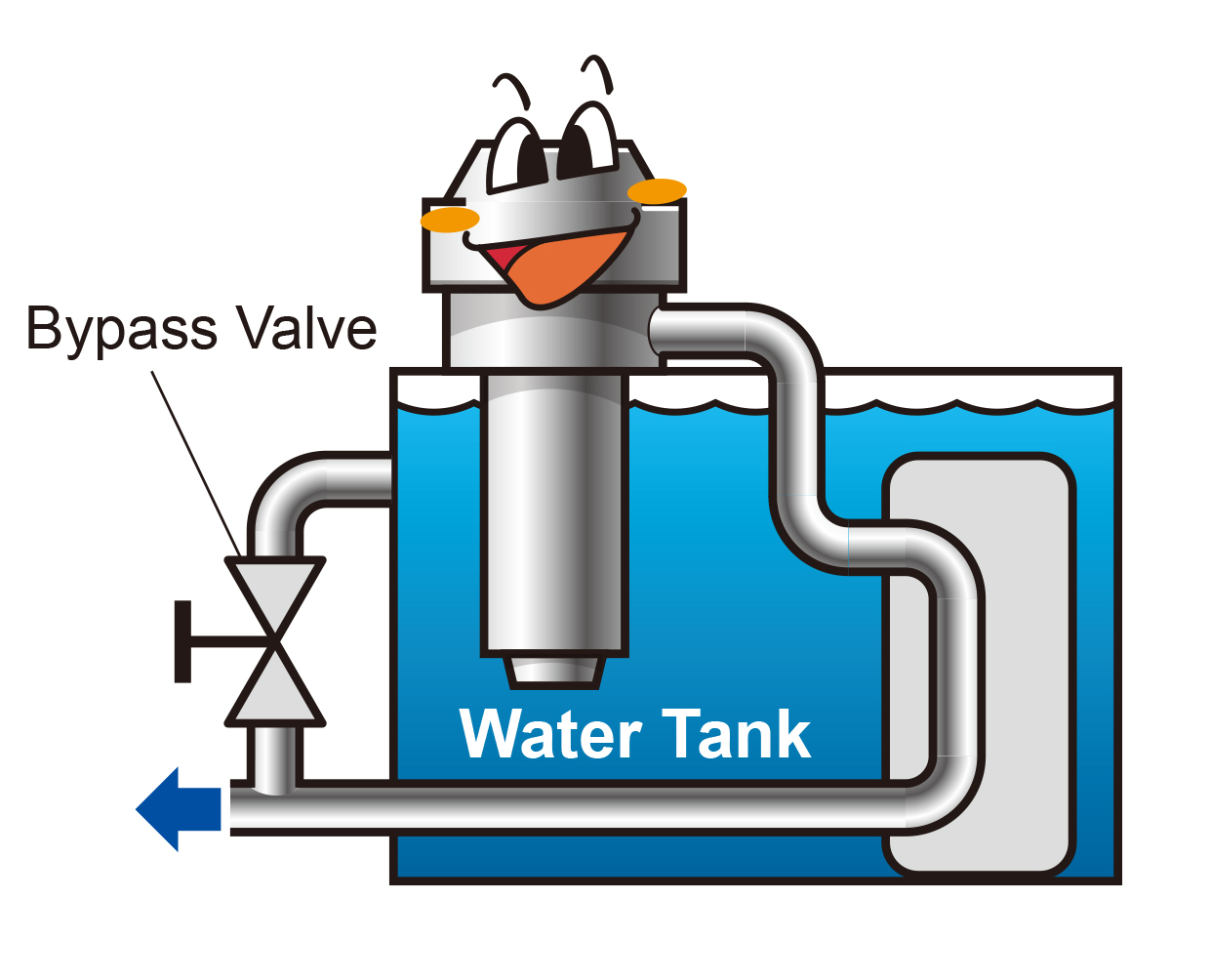

In addition to the compress or and fan, the pump is also inverter driven.

Being able to achieve just the required flow rate eliminates waste, even without bypass-valve control.

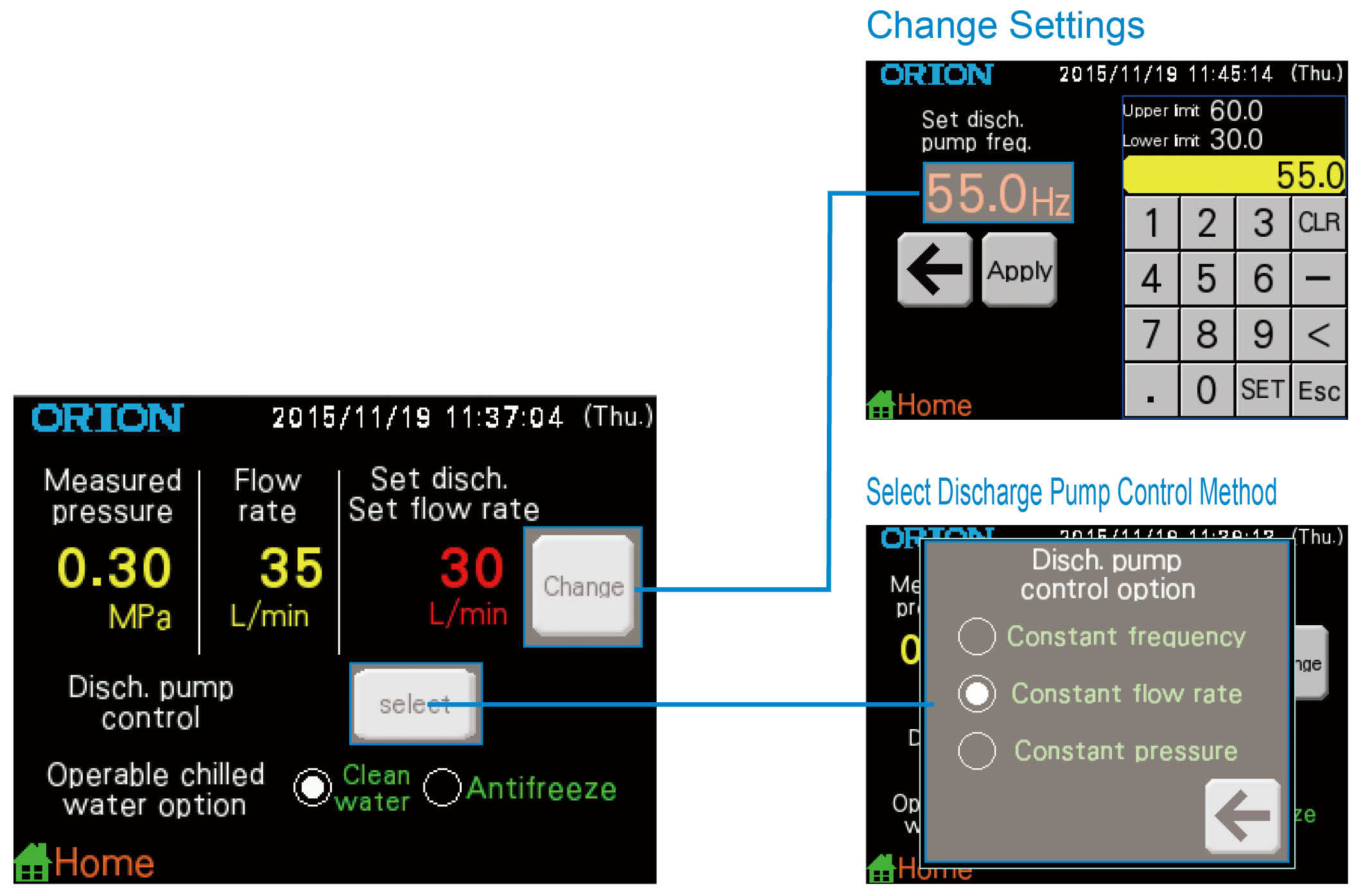

The pump control method can be selected.

In addition to setting the operating frequency, setting the flow rate or the water pressure based on an estimated flow rate standard is also possible. Operation possible at the optimum flow rate or pressure in accordance with the load.

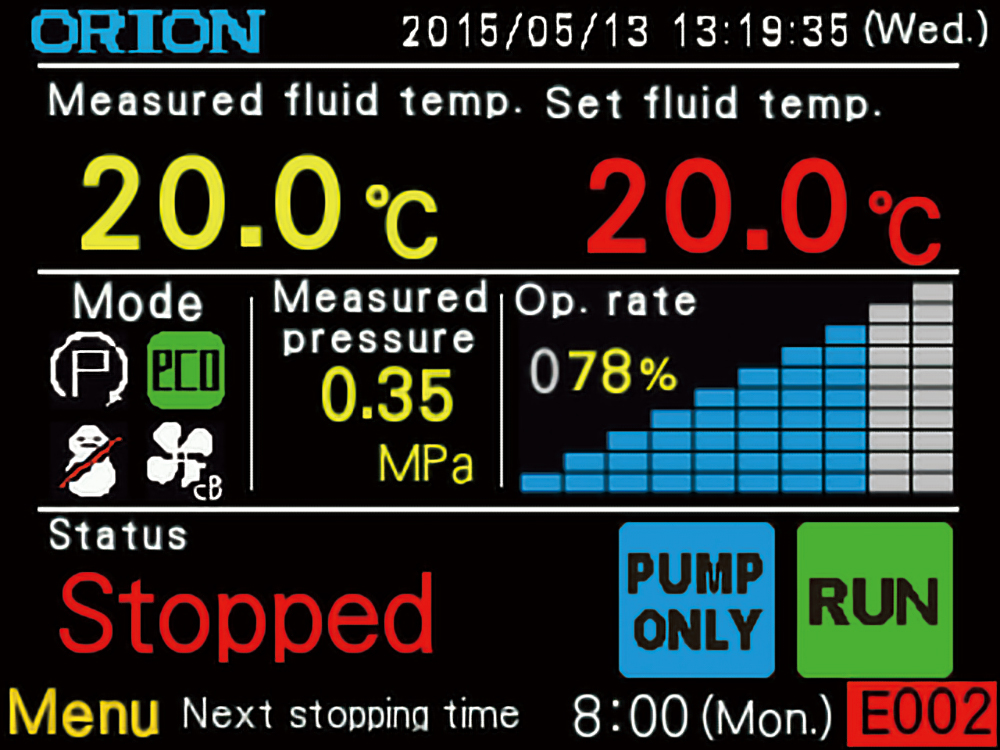

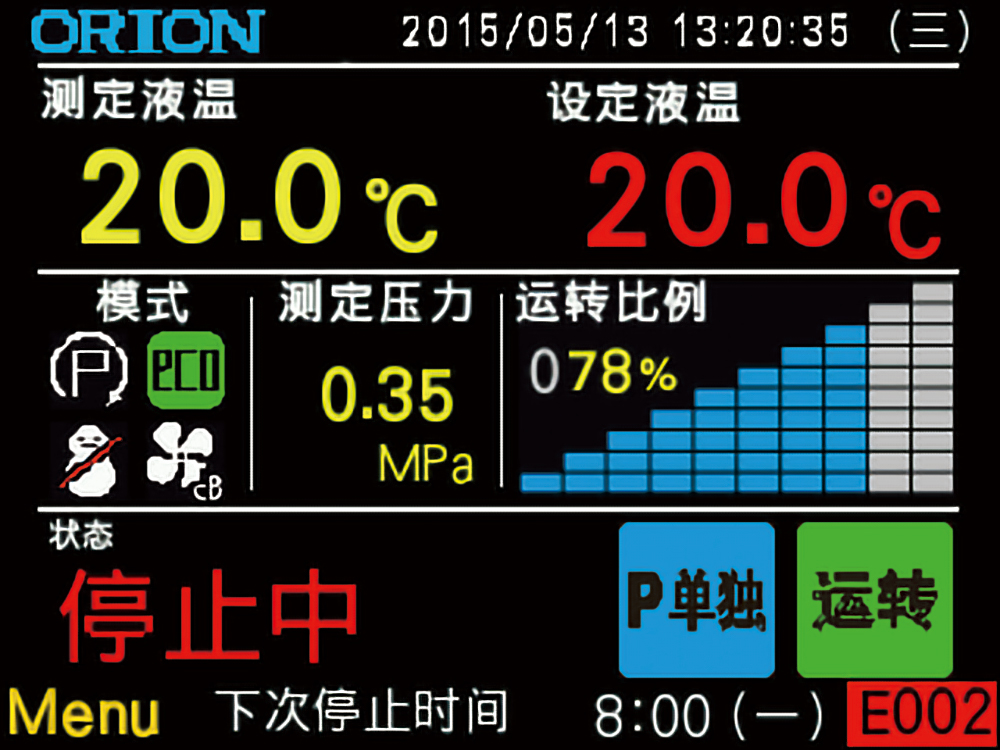

Intelligent Touch Panel

Settings and operating conditions can be visually and intuitively checked and operated via the touch panel controller.

The displayed language can be changed to English or Chinese.

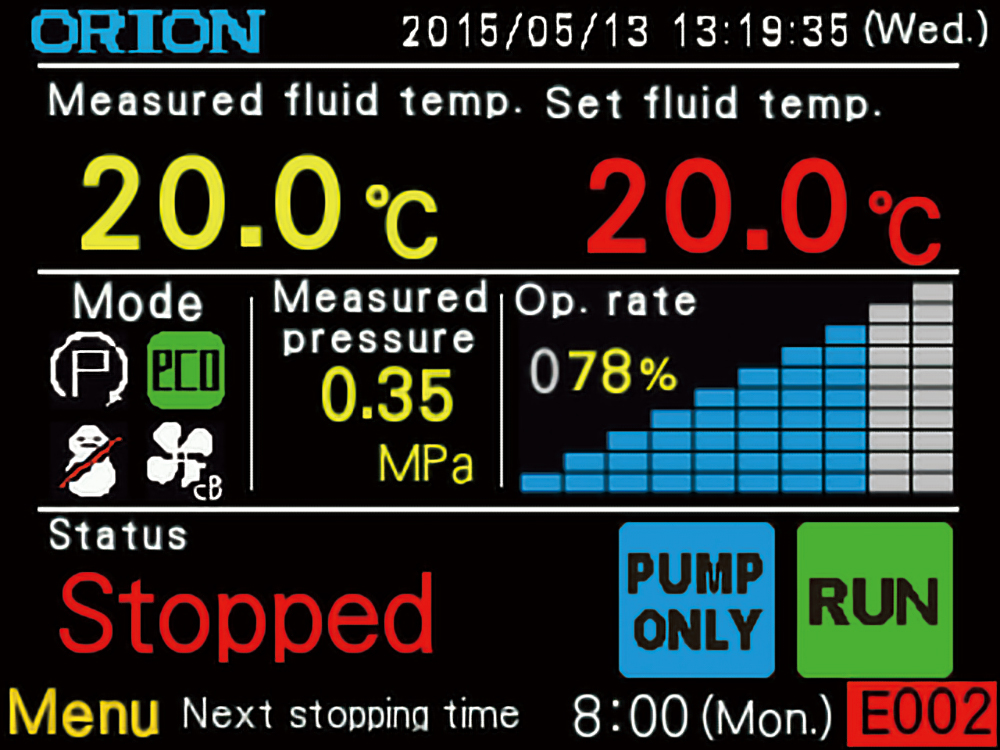

❶Graph Screen

❷Operating Rate (Power Indicator)

❸Measured Pressure

❹Menu

❺Timer Setting

❻Easy Maintenance and Alarm Display

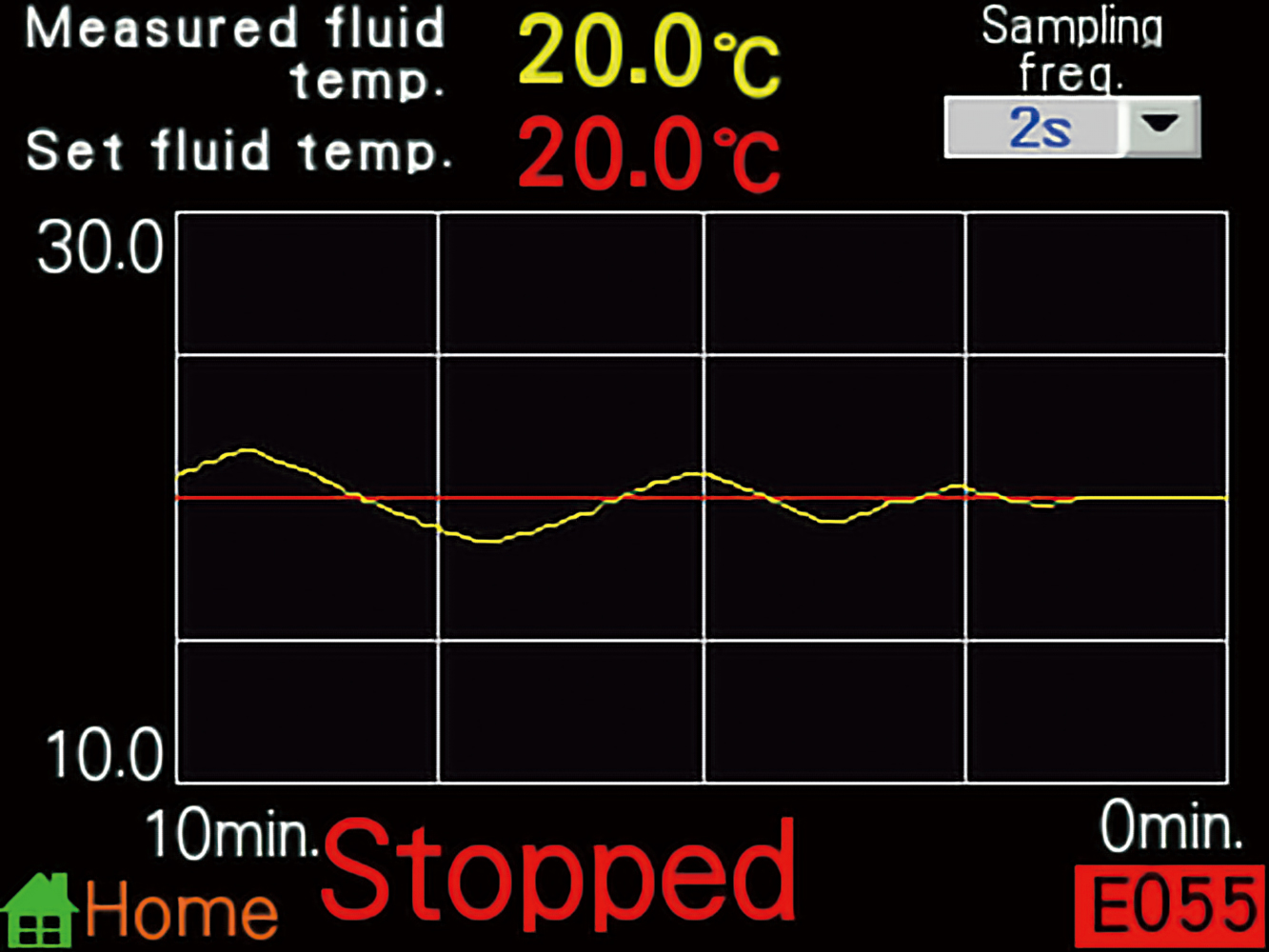

Graph Screen

Touching the "Measured Liquid Temp" button will change the display to the Graph screen where changes in liquid temperature will be graphed over a particular time period (up to 53 hours) in order to better aid in liquid temperature management.

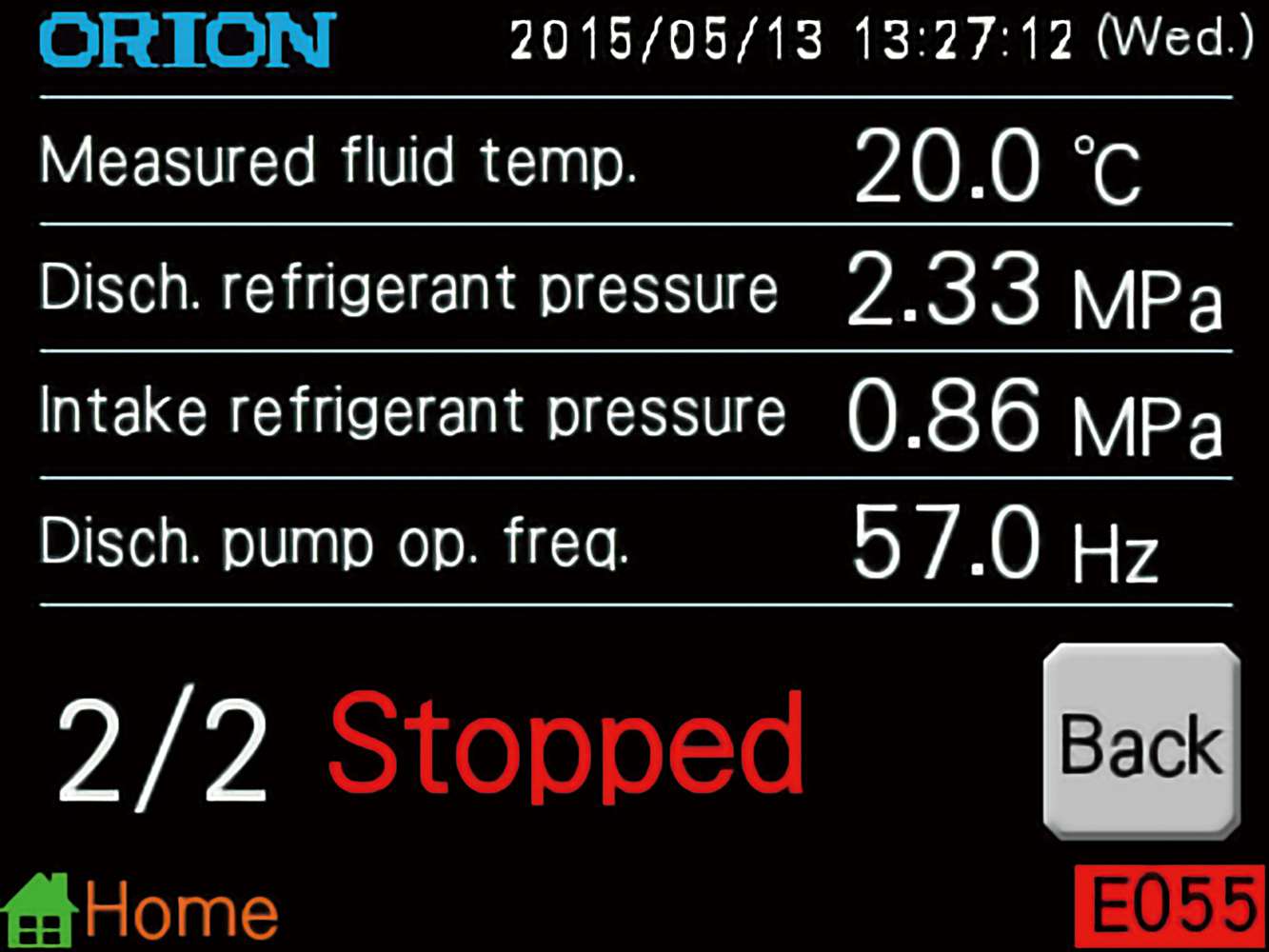

Operating Rate (Power Indicator)

The compressor operating state is indicated on a 10 level bar graph which shows the level of energy saving at a glance. Touching the "Operating Rate" button brings up the Monitor screen where operating conditions can be easily checked.

Measured Pressure

Touching "Measured Pressure" brings up a screen where the flow rate setting can easily be changed.

Menu

Touching "Menu" allows easy setting and confirmation of various parameters, error history, accumulated running time of primary components, timer functions, etc.

Timer Setting

Touch the "0:00:00" start time allows setting of designated start/stop settings. Actions can be repeated or set according to the day.

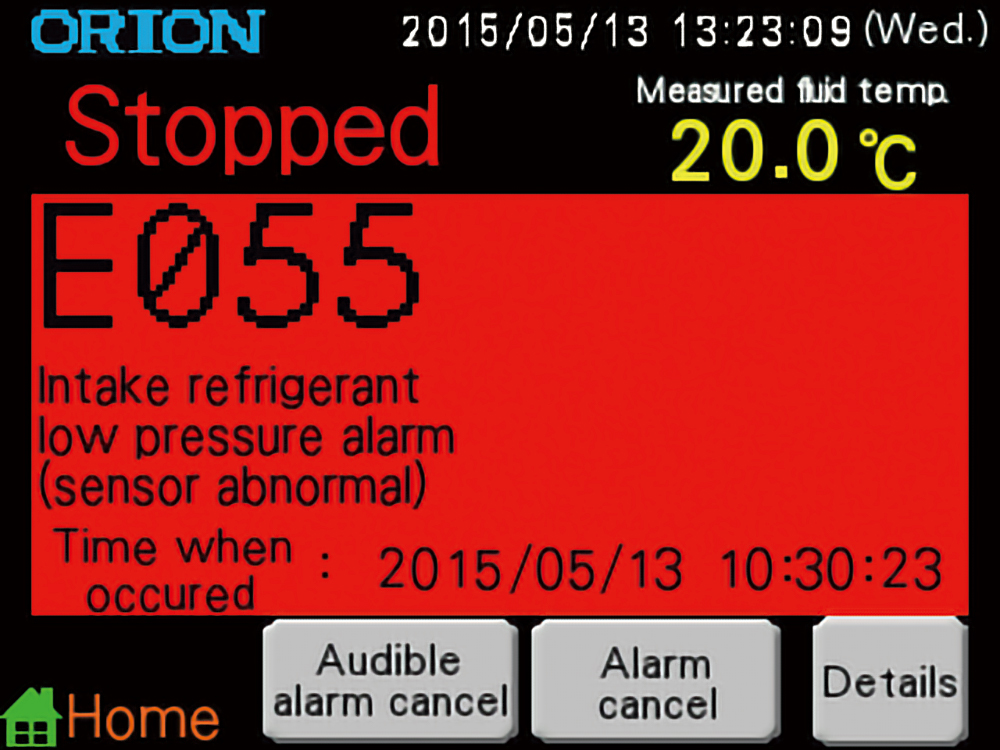

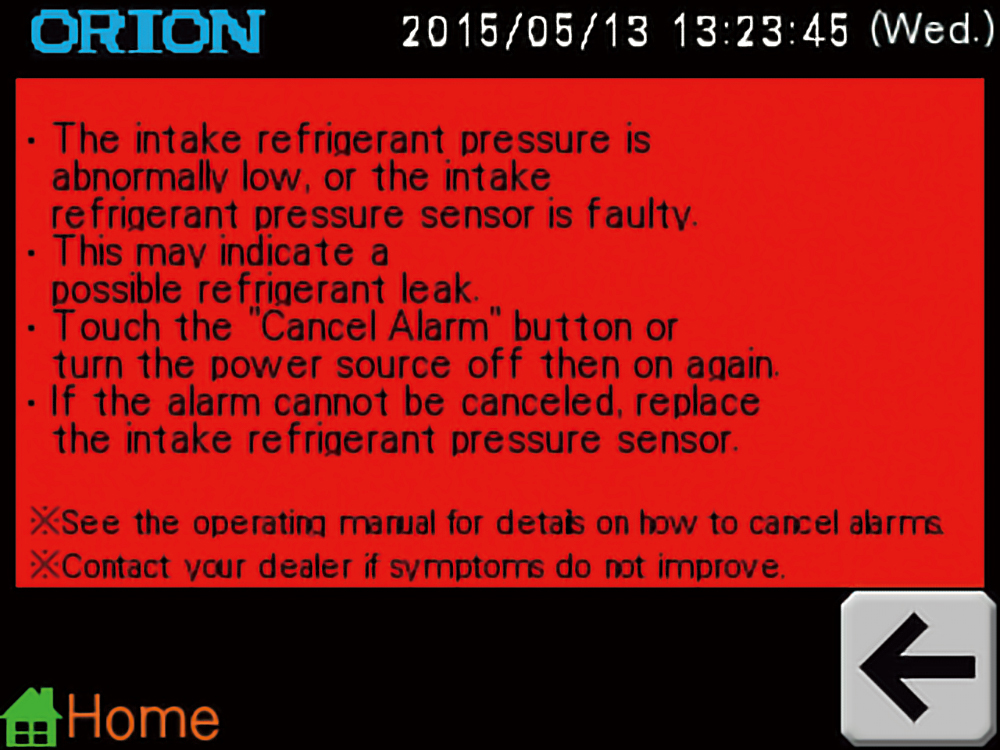

Easy Maintenance and Alarm Display

Alarm numbers are displayed when alarm conditions occur.

Touching the "Details" button will bring up further details about the alarm and information on what measures to take.

The display language can be changed.

Operation and Monitoring Via PC or Sequencer Possible

Communications functions can be utilized through a control program to match your specific application.

Detailed display functions enable quick recovery!

・Inspection Warnings Liquid

・Temperature Warnings

・Water Pressure

・Refrigeration Circuit

・Inverter, Etc.

Communications Method

USB: 1 Unit, RS-422A: 32 Units, RS-485: 32 Units

Items that can be controlled via PC:

・Starting and stopping of individual chiller units.

・Individual operation of chiller discharge pumps.

・Liquid temperature control of individual chillers.