Features

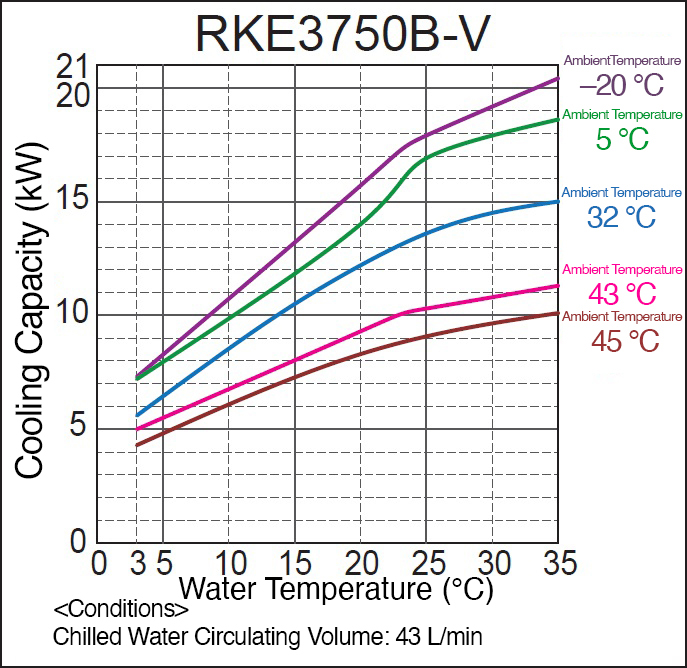

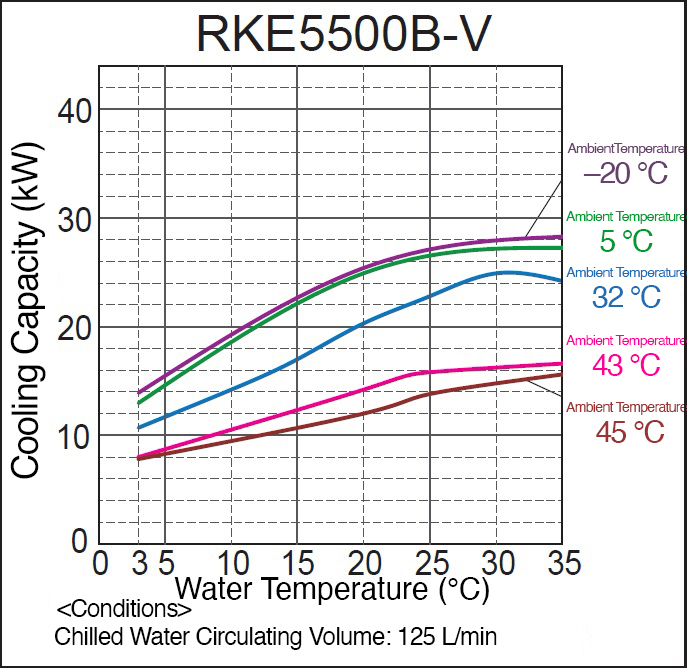

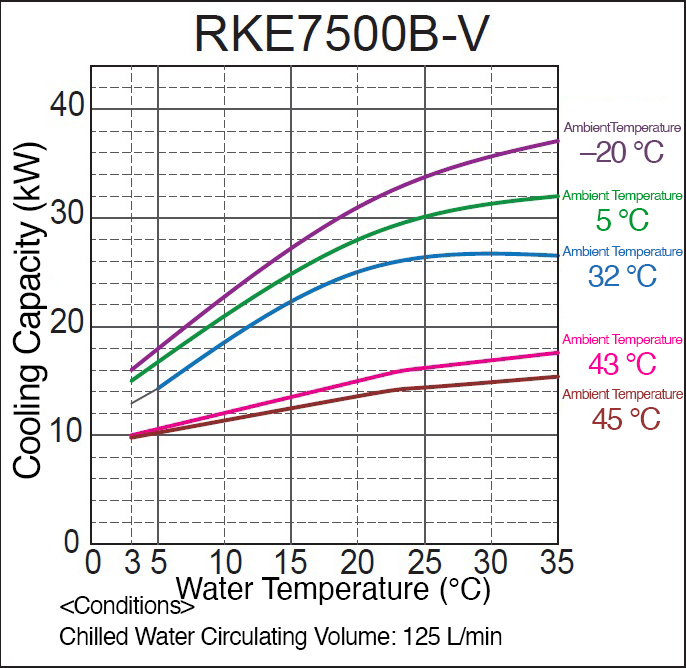

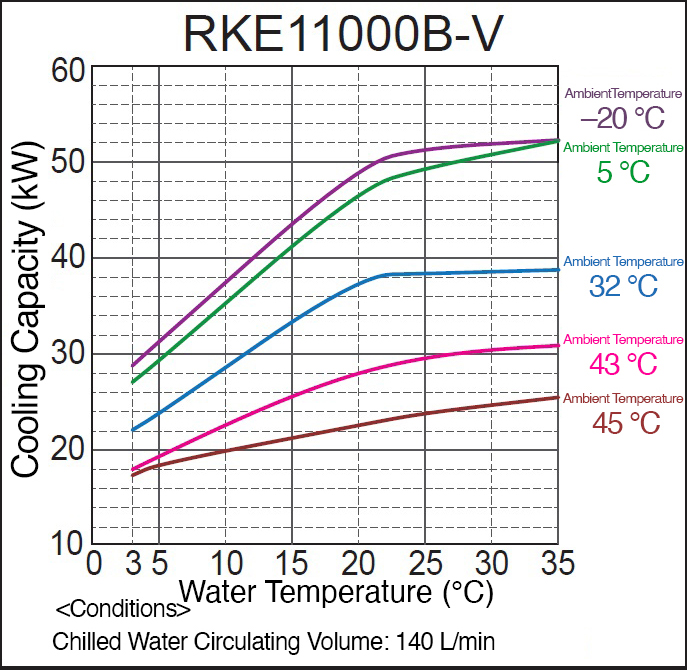

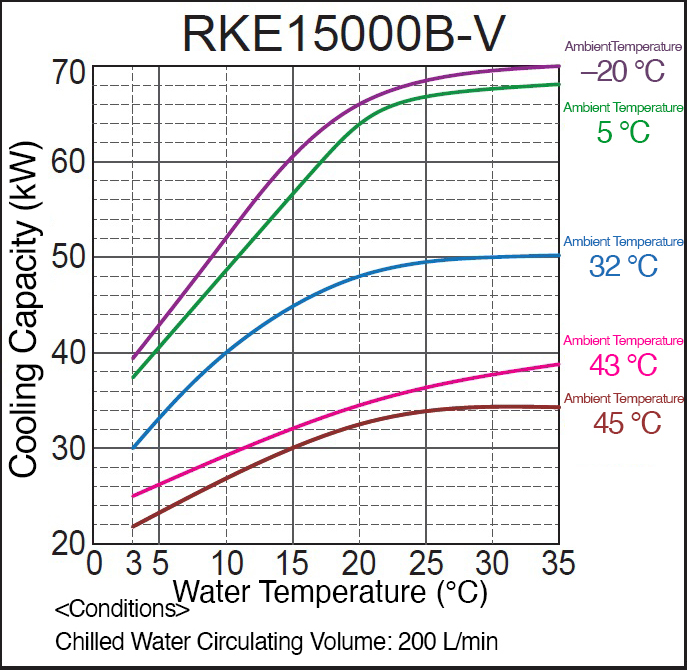

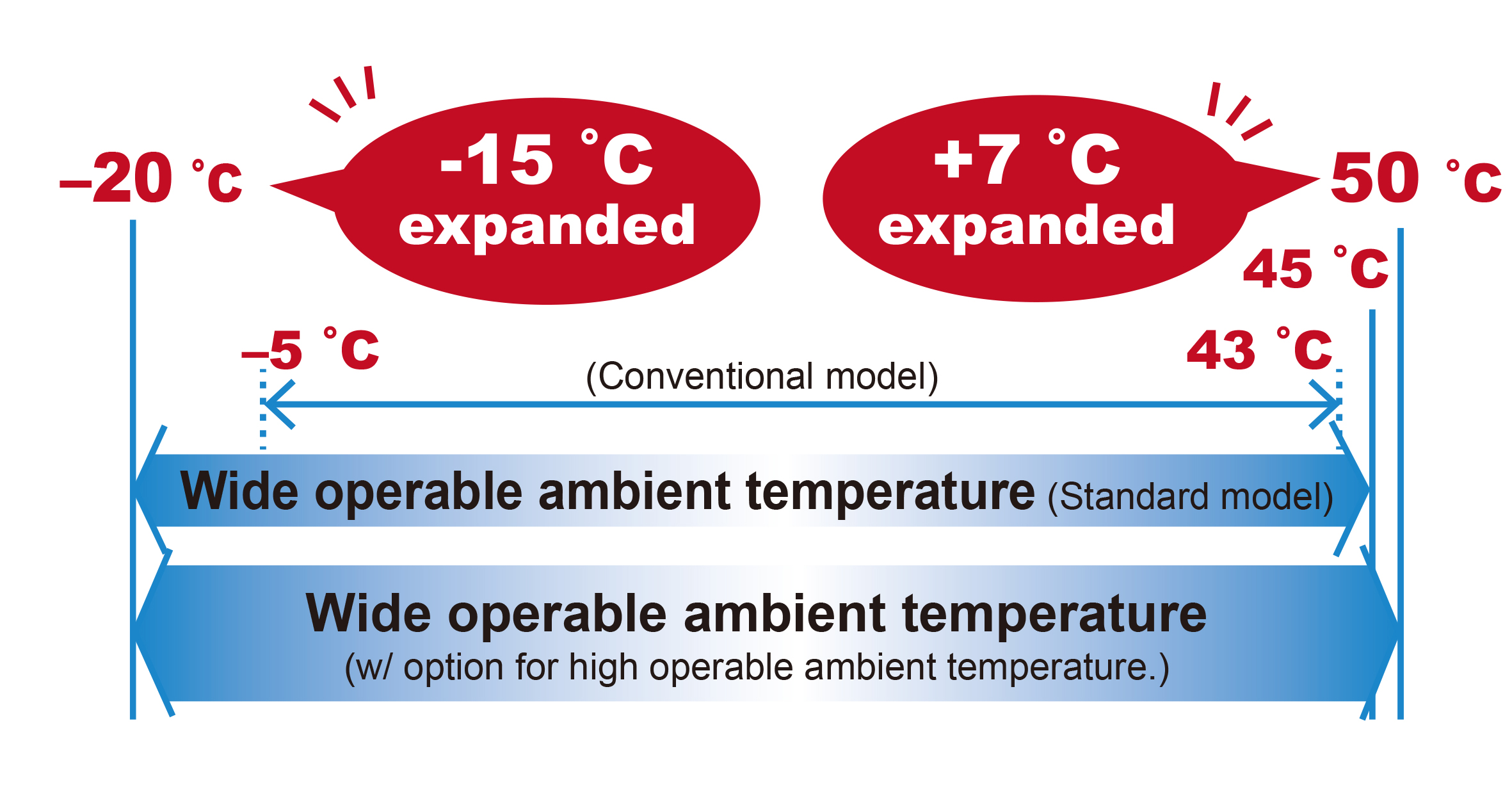

Wider Operable Ambient Temperature Range

Can tolerate up to 50 °C summers with its harsh-condition specifications. (Optional setting required.)*1 Our chillers can also exhibit maximum performance in factory environments where hot air flows tend to accumulate. Not only that, but you can count on continuing performance even in outside installations at winter temperature as cold as –20 °C.*2

*1 Does not apply to RKE15000B-VW models.

*2 Air-cooled models only. Requires freeze-prevention mode to be enabled.

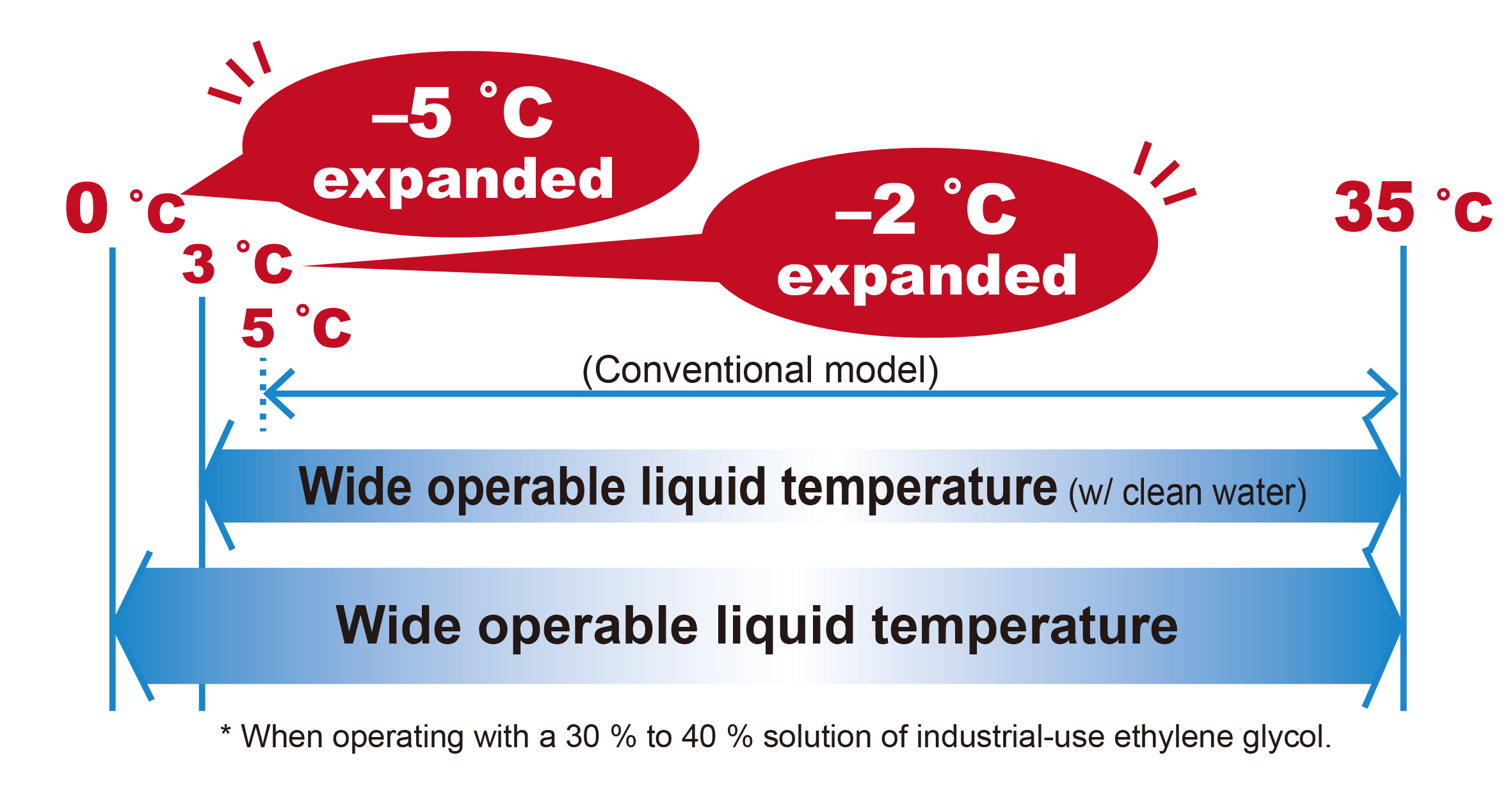

Wider Operating Temperature Range (Liquid Temperature)

The operating temperature (liquid temperature) range has widened even further in the low region with a range of 3 to 35 °C.

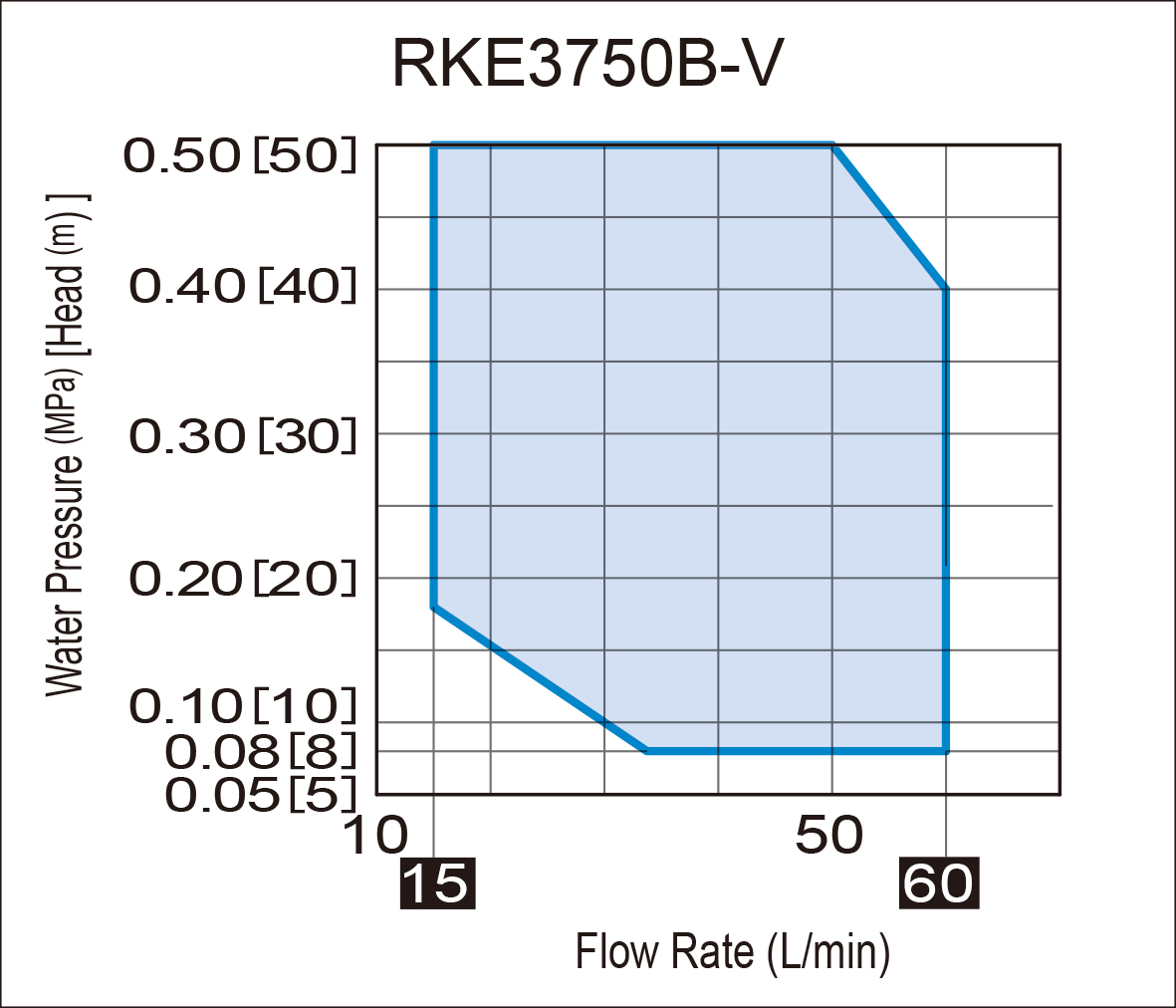

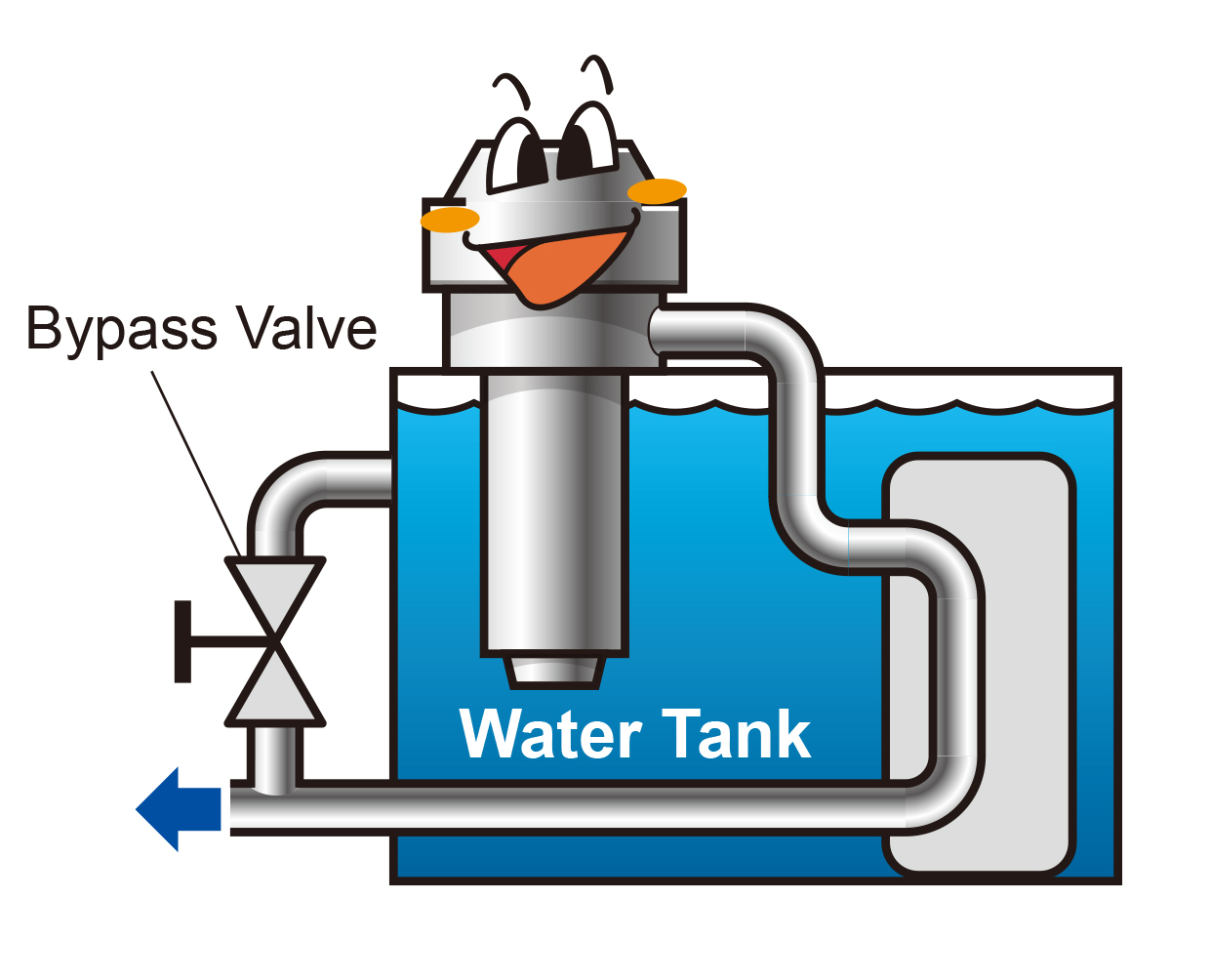

Pump is also Inverter Driven

The compressor, and the fan AND the pump are Inverter Driven!

Being able to achieve just the required flow rate eliminates waste, even without bypass-valve control.

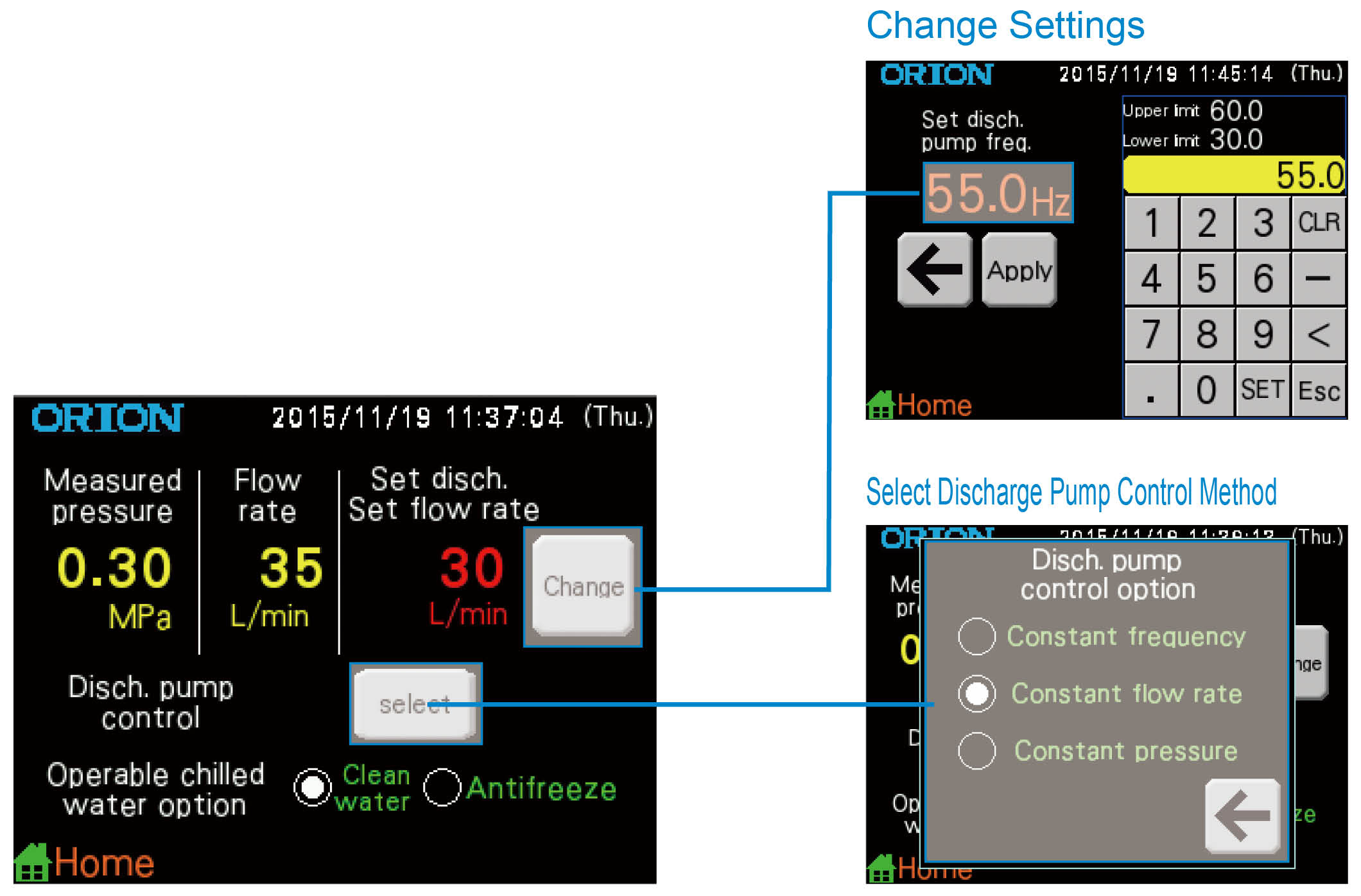

The pump control method can be selected.

In addition to setting the operating frequency, it is also possible to set the flow rate based on an estimated flow rate standard, or set the water pressure. Operation possible at the optimum flow rate or pressure in accordance with the load.

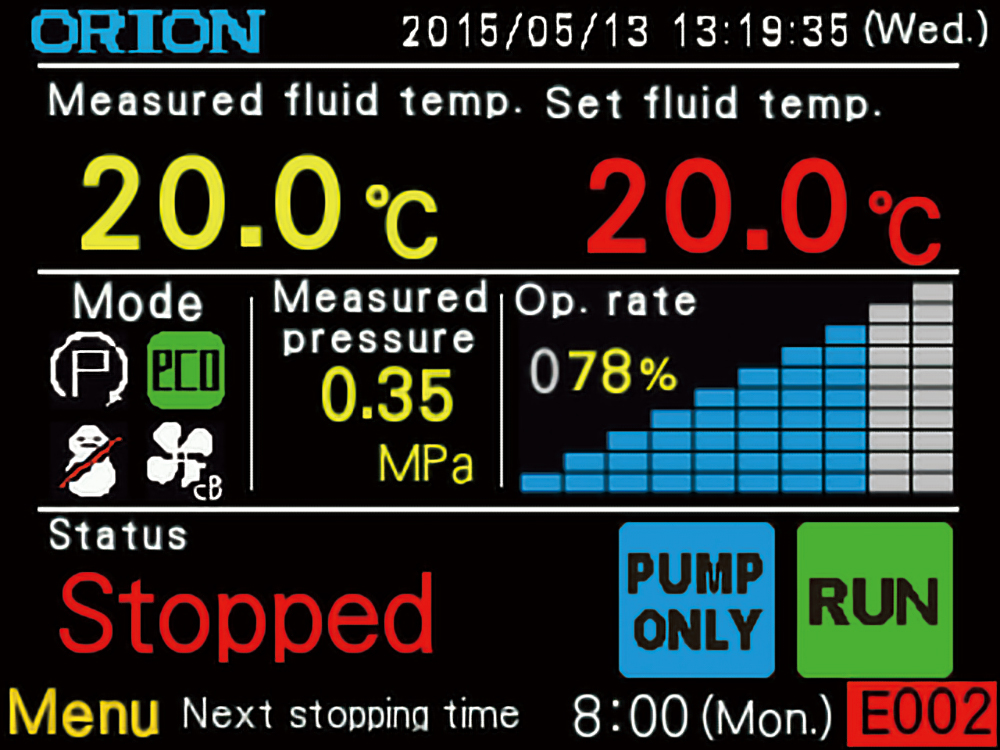

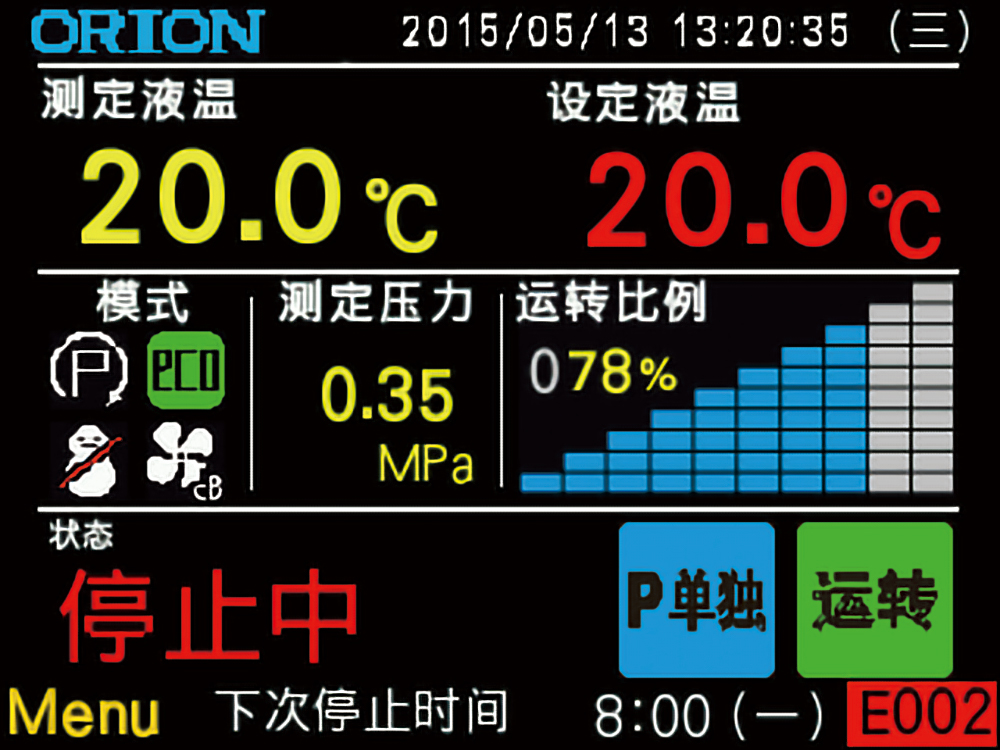

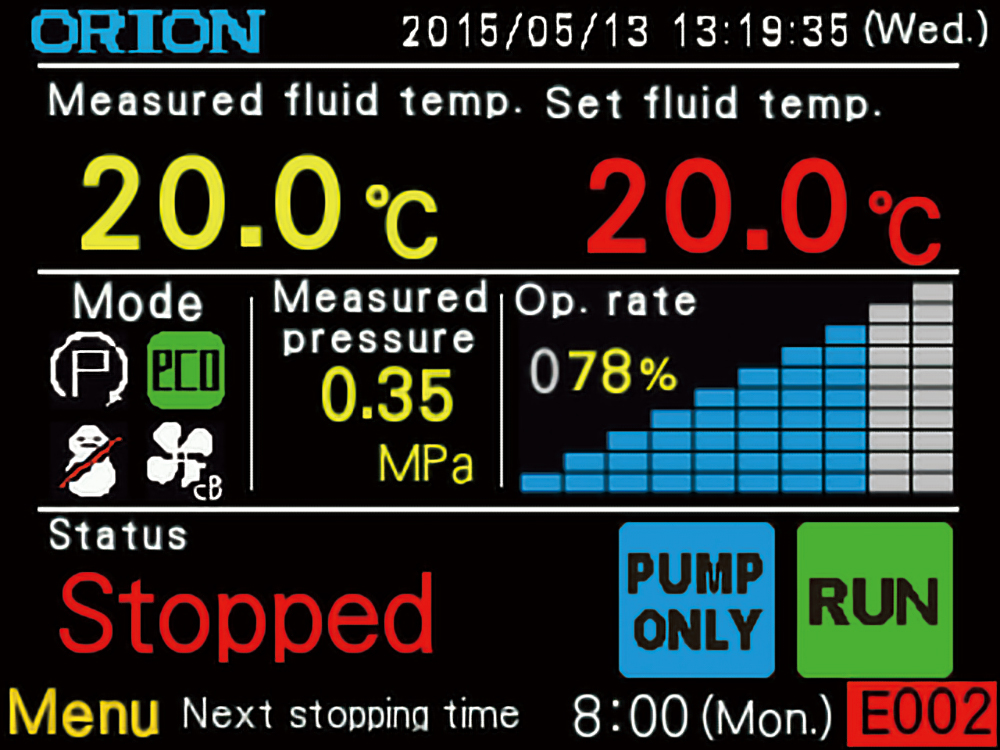

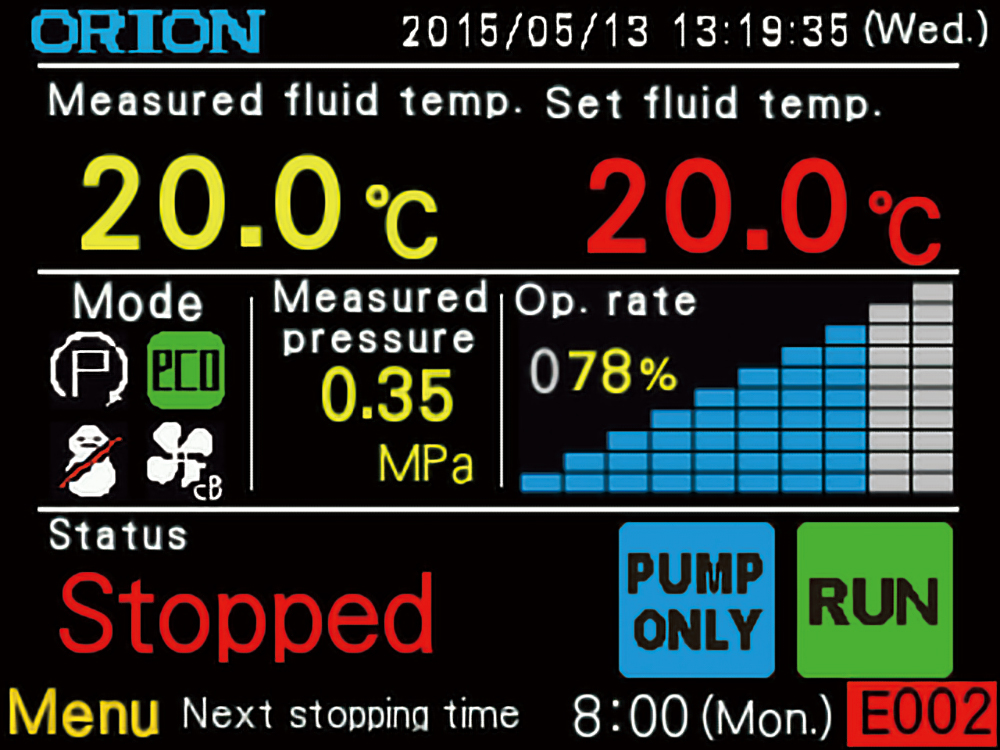

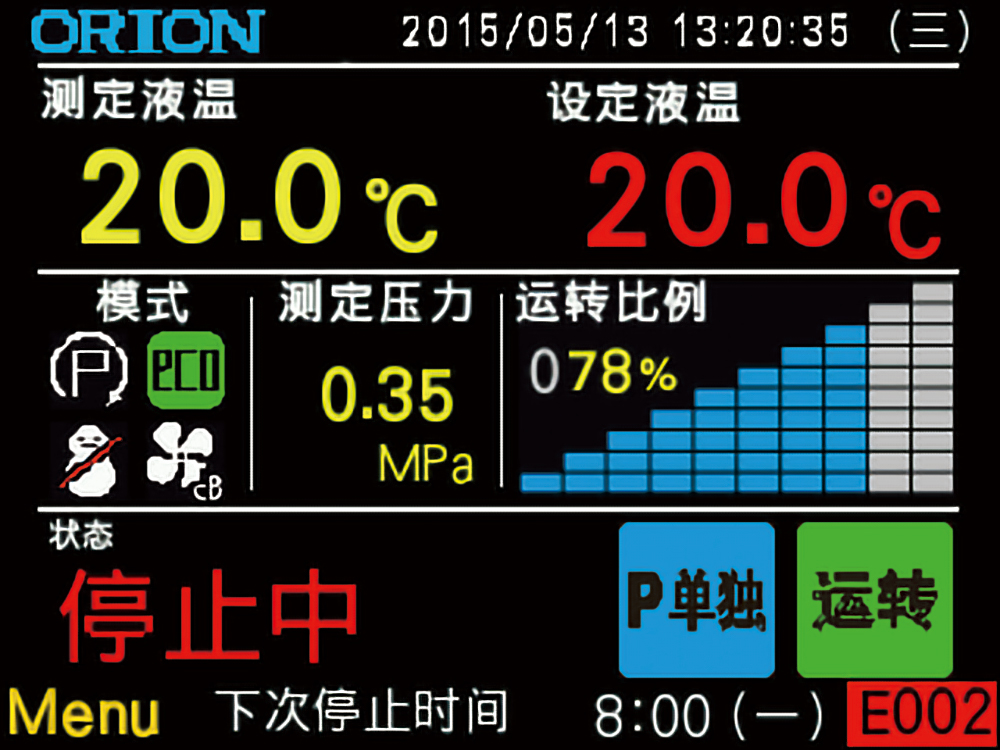

Intelligent Touch Panel

Settings and operating conditions can be visually and intuitively checked and operated via the touch panel controller.

The displayed language can be changed to English or Chinese.

❶Graph Screen

❷Operating Rate (Power Indicator)

❸Measured Pressure

❹Menu

❺Timer Setting

❻Easy Maintenance / Alarm Display

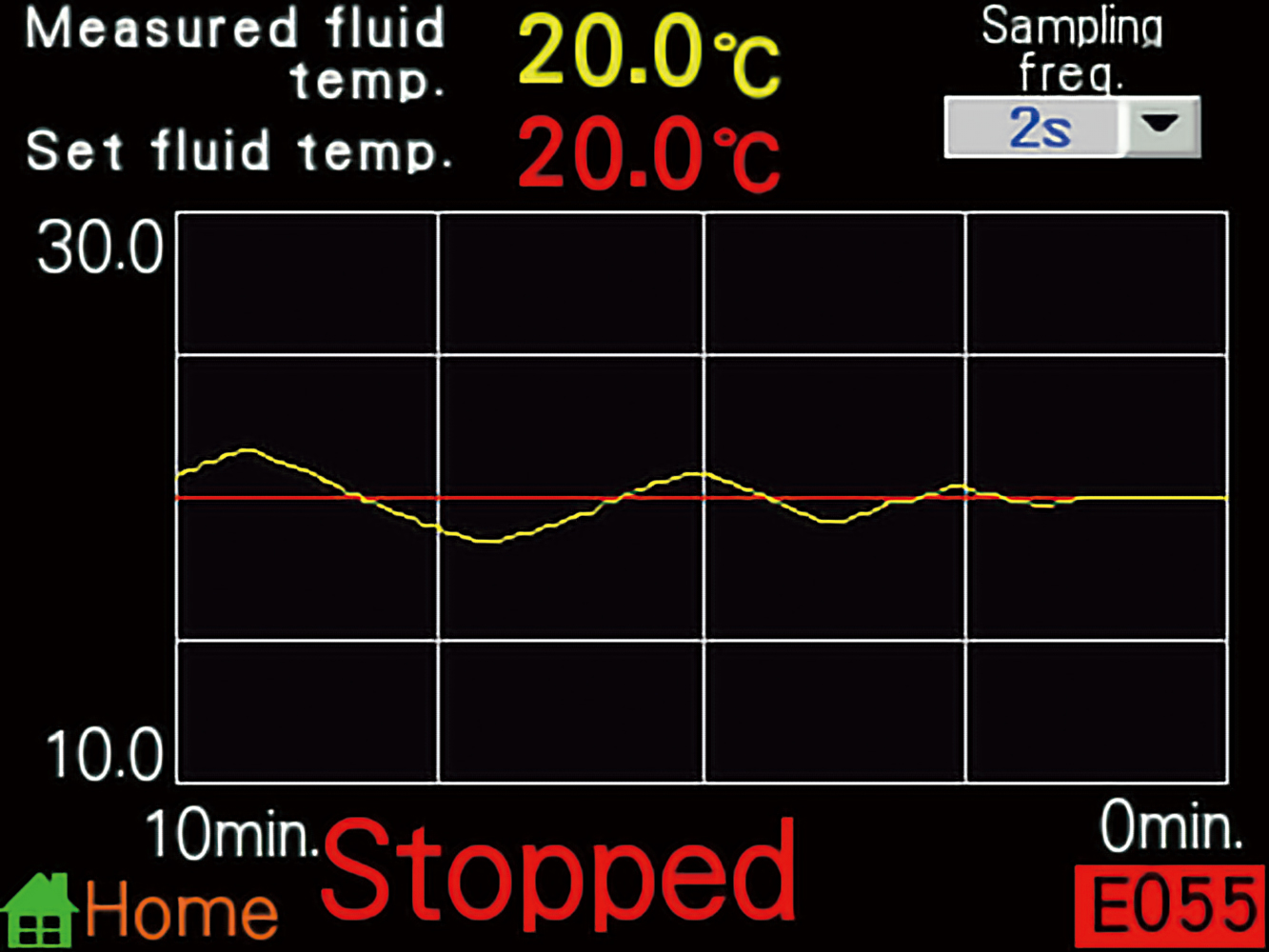

Graph Screen

Easy operation with just the flick of a switch!Error code display gives important information about the alarm. Allows for quick restore after an issue.

Touching the "Measured Liquid Temp" button will change the display to the Graph screen where changes in liquid temperature will be graphed over a particular time period (up to 53 hours) in order to better aid in liquid temperature management.

Operating Rate (Power Indicator)

Easy operation with just a press of a button!Error code display gives important information about the alarm. Allows for quick restore after an issue.

Shows the operating state of the compressor on a 10-level display to allow for easy confirmation of current operating conditions.

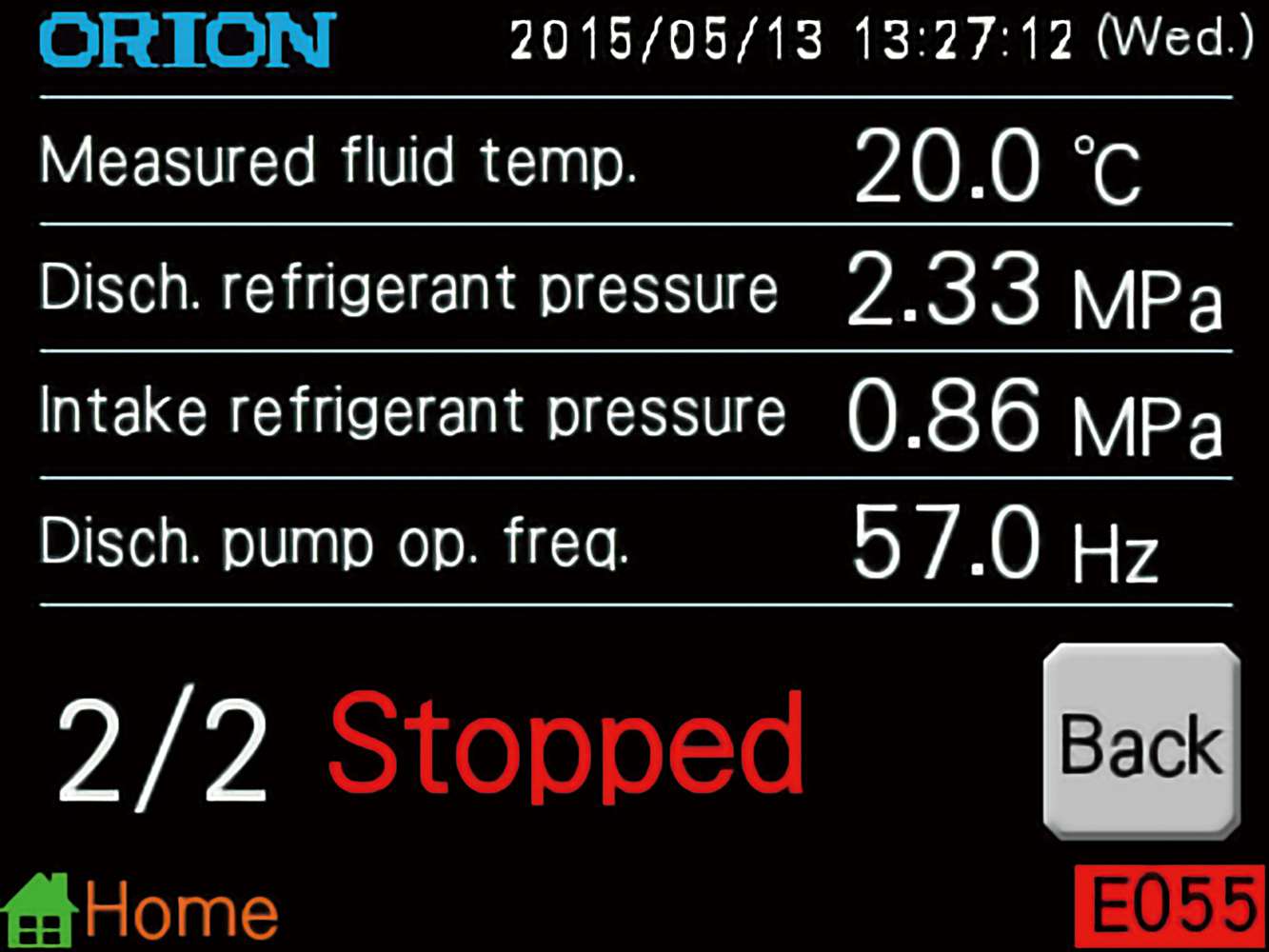

Measured Pressure

Touching "Measured Pressure" brings up a screen where the flow rate setting can easily be changed.

Menu

Touching "Menu" allows easy setting and confirmation of various parameters, error history, accumulated running time of primary components, timer functions, etc.

Timer Setting

Touching the "0:00:00" start time allows setting of designated start/stop settings. Actions can be repeated or set according to the day.

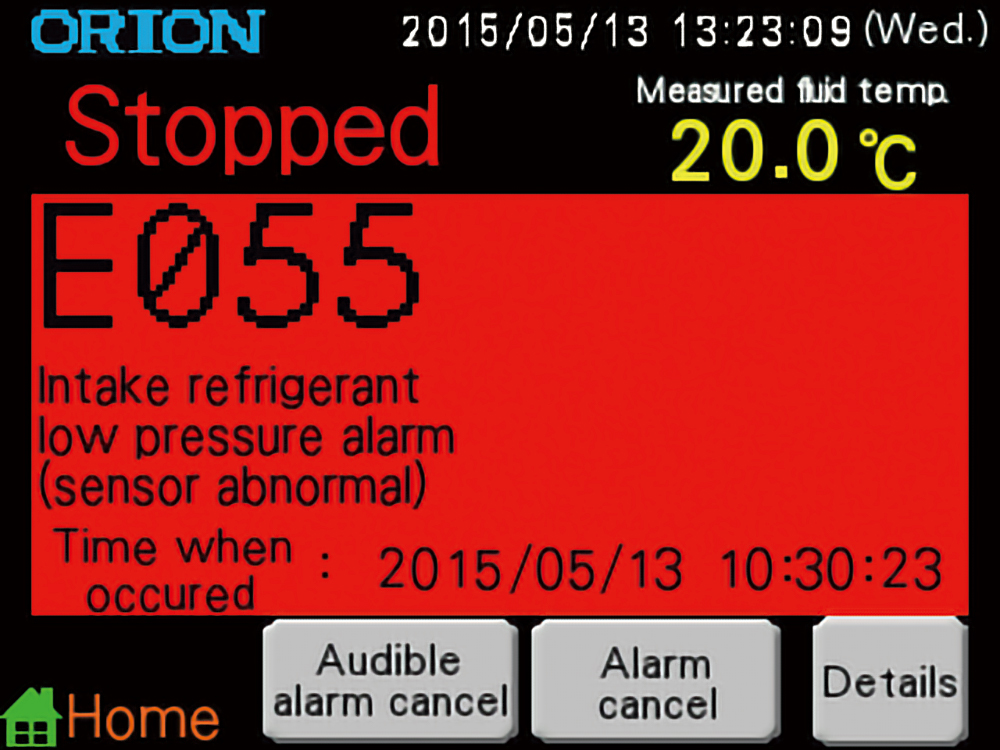

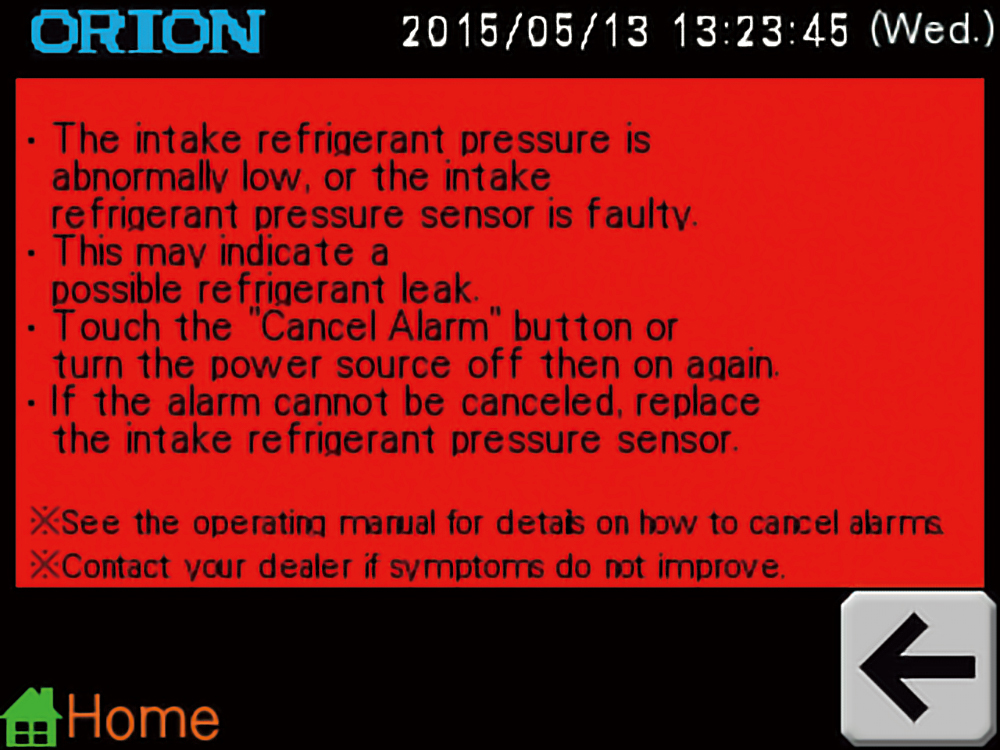

Easy Maintenance / Alarm Display

Alarm numbers are displayed when alarm conditions occur.

Touching the "Details" button will bring up further details about the alarm and information on what measures to take.

The display language can be changed.

English

English Chinese

Chinese

Low Noise and Noise Reducing Design

Ideal inverter fan speed control through optimized refrigeration cycle control. Operating noise has been greatly reduced. Operating noise level measured from a position of 1 m in front and at a height of 1 m.

Operation and Monitoring via PC or Sequencer Possible

Communications functions can be utilized through a control program to match your specific application.

Detailed display functions enable quick recovery!

・Inspection Warning

・Liquid Temperature Warning

・Water Pressure

・Refrigeration Circuit

・nverter etc.

Communications Method

USB: 1 Unit, RS-422A: 32 Units, RS-485: 32 Units

Items that can be controlled via PC:

・Starting and stopping of individual chiller units.

・Individual operation of chiller discharge pumps.

・Liquid temperature control of individual chillers.

Meets the Demands of World Markets

・CE Marking and RoHS Compliant Models Available

・Other International Standards

For inquiries, please contact us via our web site.

Applications

We have a page that highlights applications of the RKE Series water chillers. Have a look!

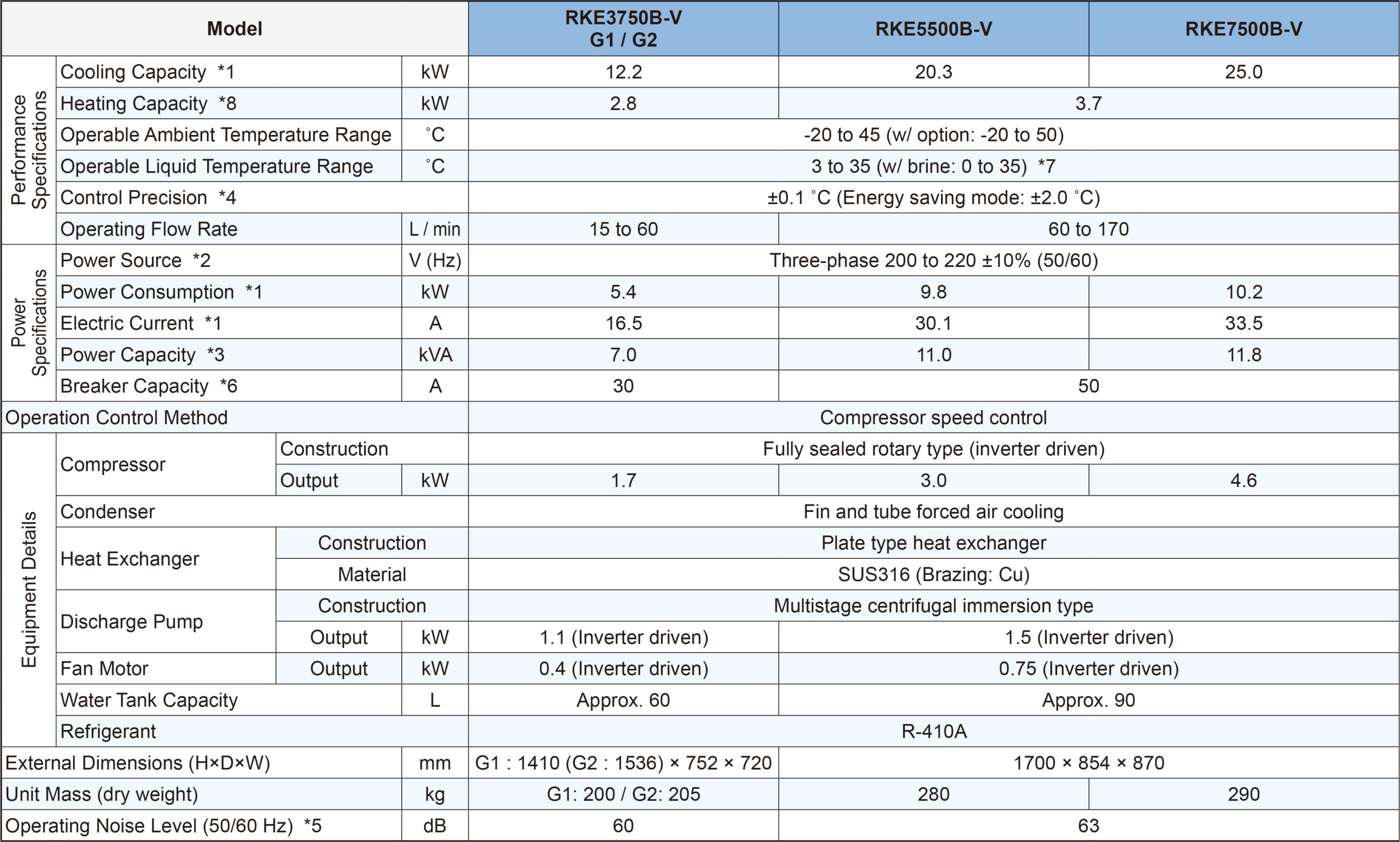

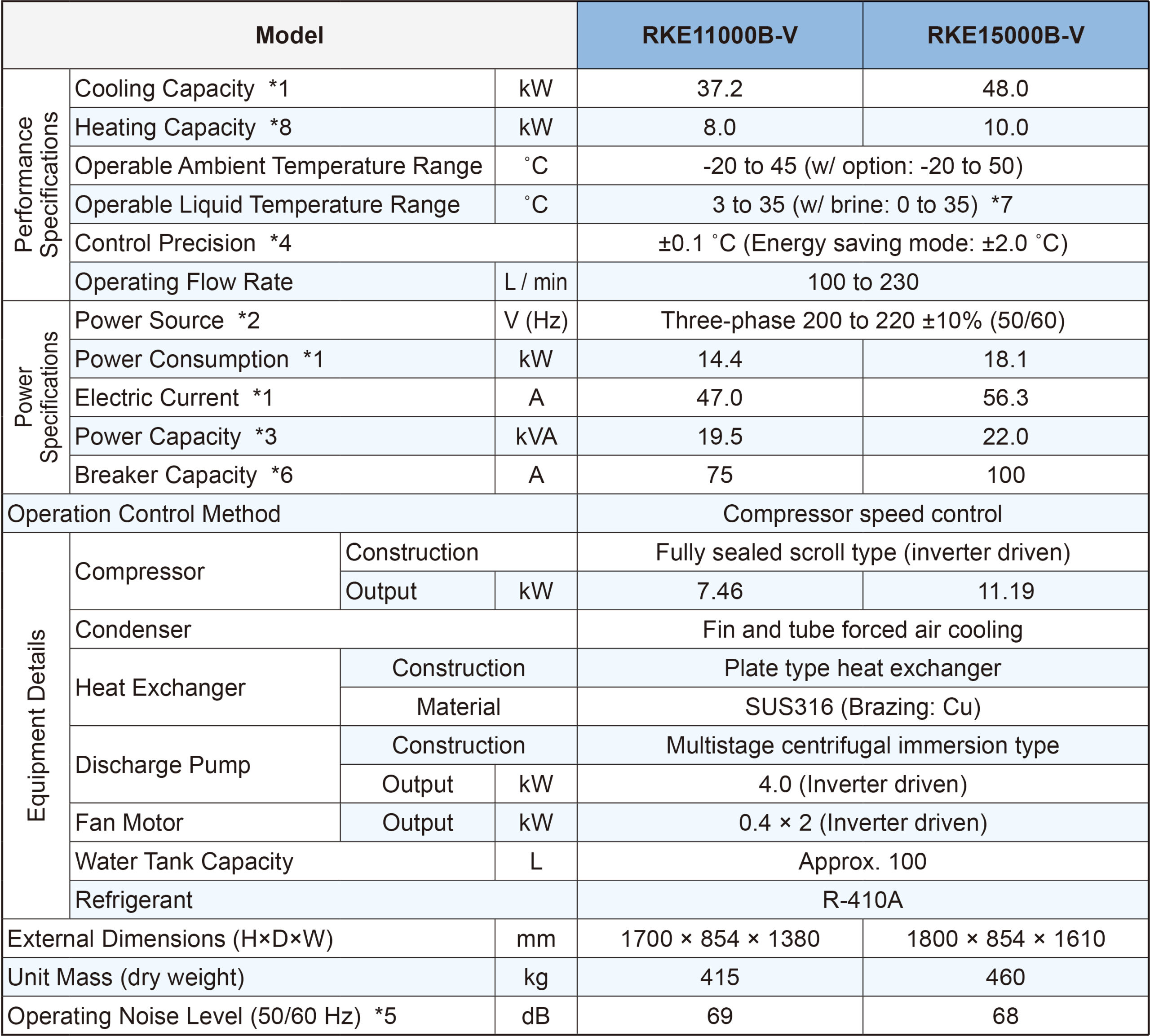

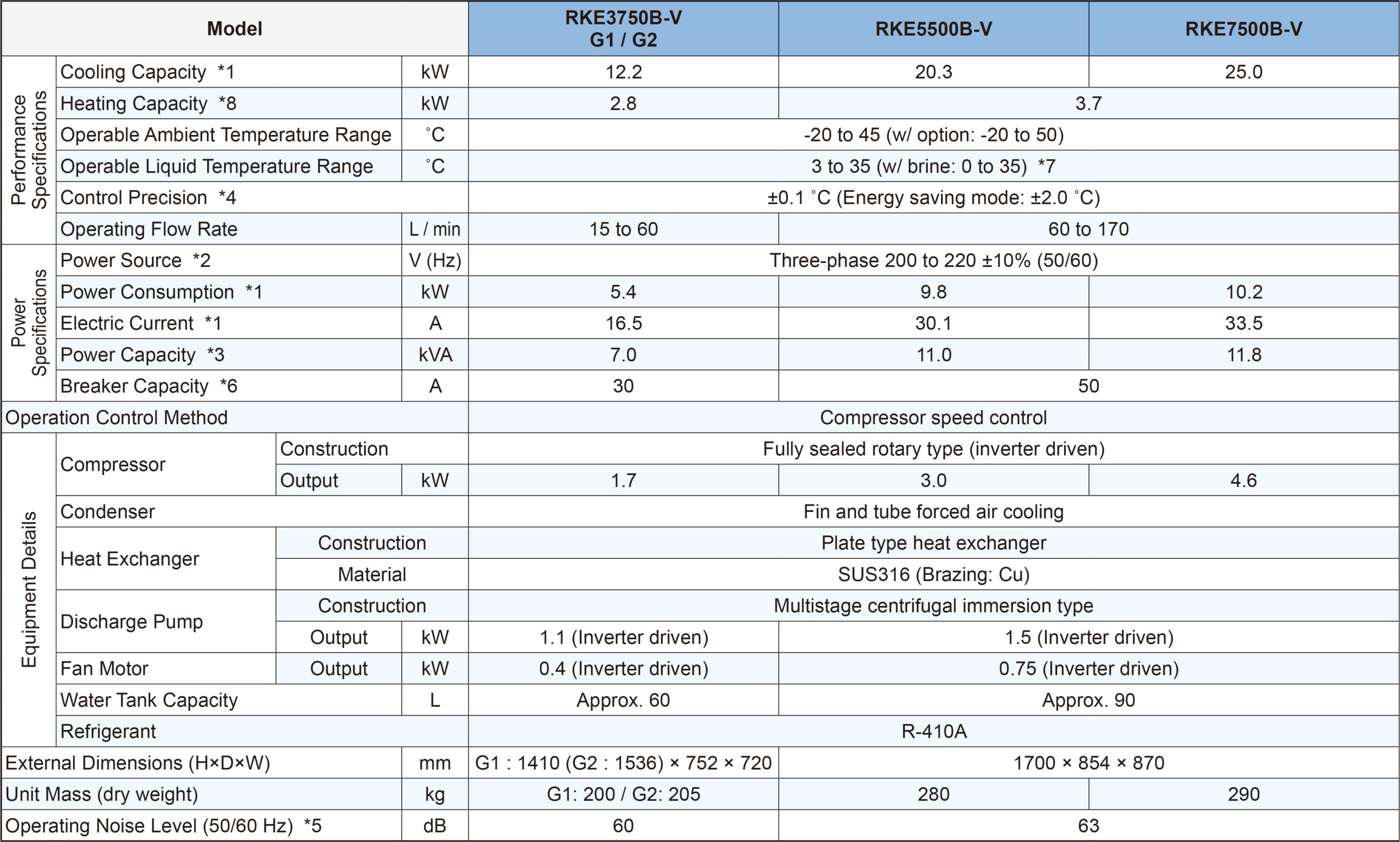

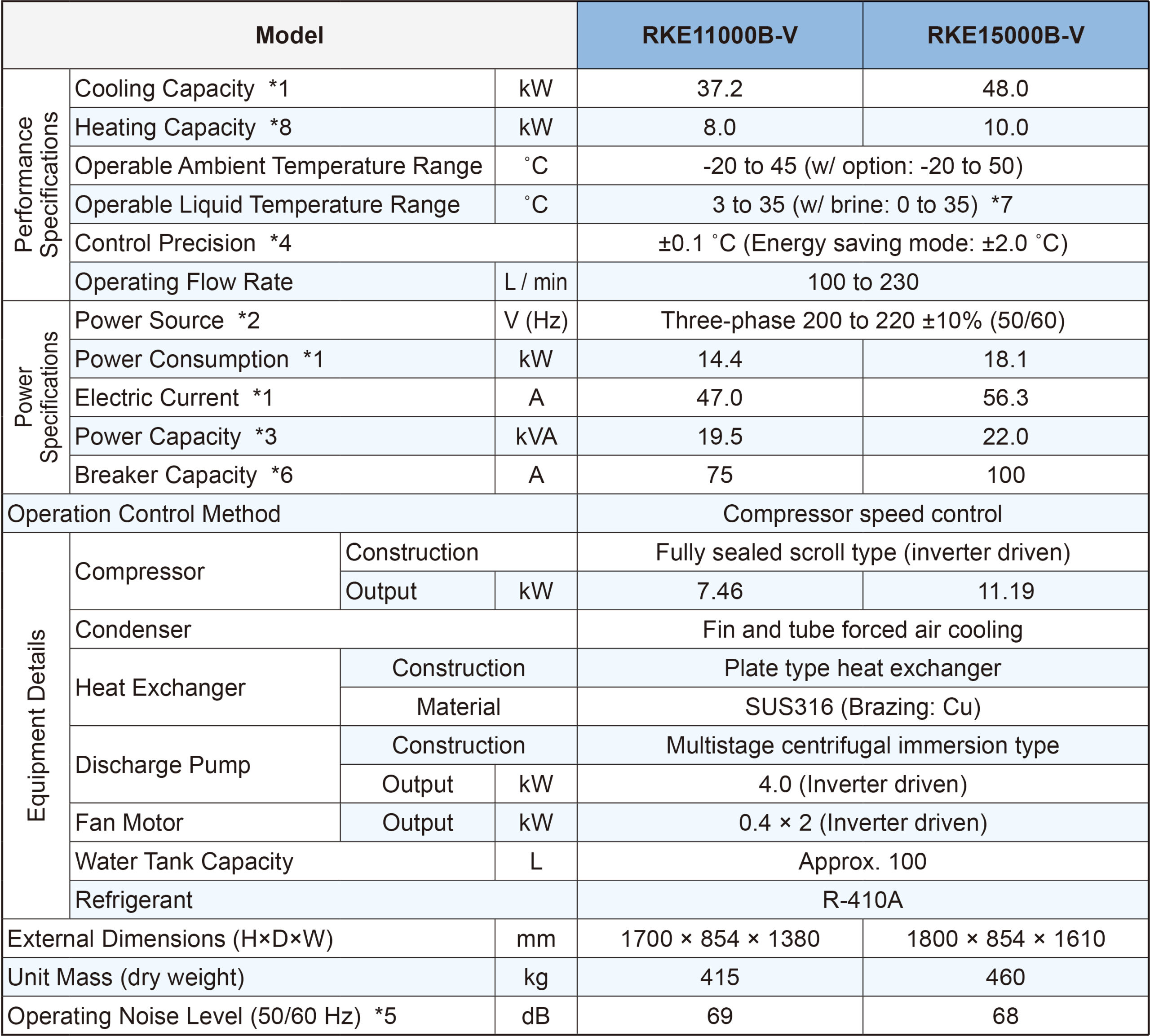

[Air Cooled] Specifications

*1 When operating with cooling water temp: 20 °C; ambient temp: 32 °C. Cooling capacity will be at least 95% of the displayed power.

*2 Only during startup, and will differ depending on the ambient temperature.

*3 Continuous current load fluctuation within ±10%, and with stable ambient temperature and power supply, etc. Does not include starting times or when the compressor may cycle on and off due to very low cooling loads.

*4 The source voltage phase unbalance should be within ±3%.

*5 The figure noted is when the product is operating at the highest capacity within its normal operating range.

*6 Comes standard with a built-in multi-purpose overload and short circuit protection earth leakage breaker.

*7 Operating noise levels are from a position of 1 m in front of the product and at a height of 1 m.

*8 If operating with a set temperature down to 0 to 3 °C, then use a 30% to 40% solution of industrial-use ethylene glycol.

Note 1: The recommended liquid (chilled water) for use in this product is clean water or a 30% to 40% solution of industrial-use ethylene glycol. However, when doing so, there will be a 10% drop in cooling capacity. Alternatively, if conditioned water is used, then it should have an electrical conductivity of at least 1 µS/cm.

Note 2: Heat output from the product (in kW) is approx. 1.3 times that of the cooling capacity.

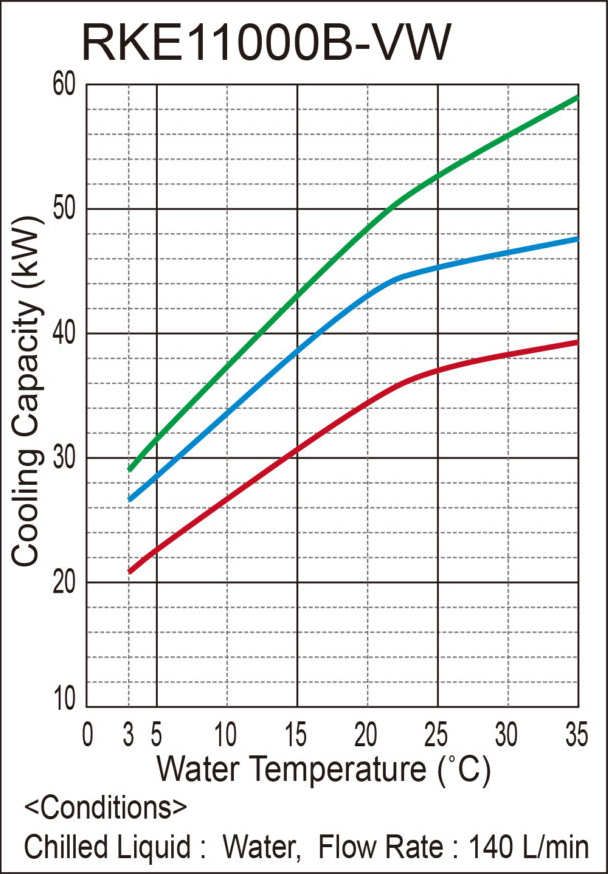

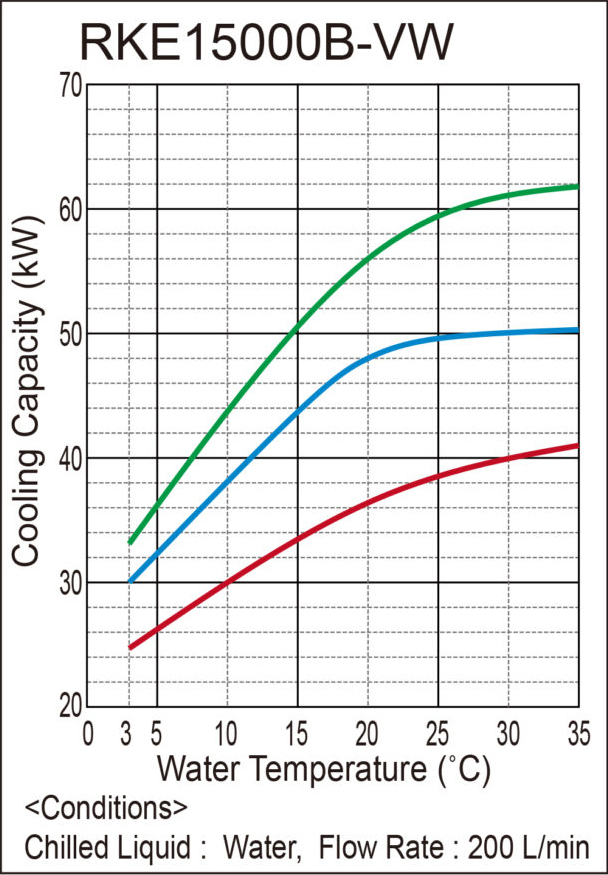

[Air Cooled] Performance Specifications

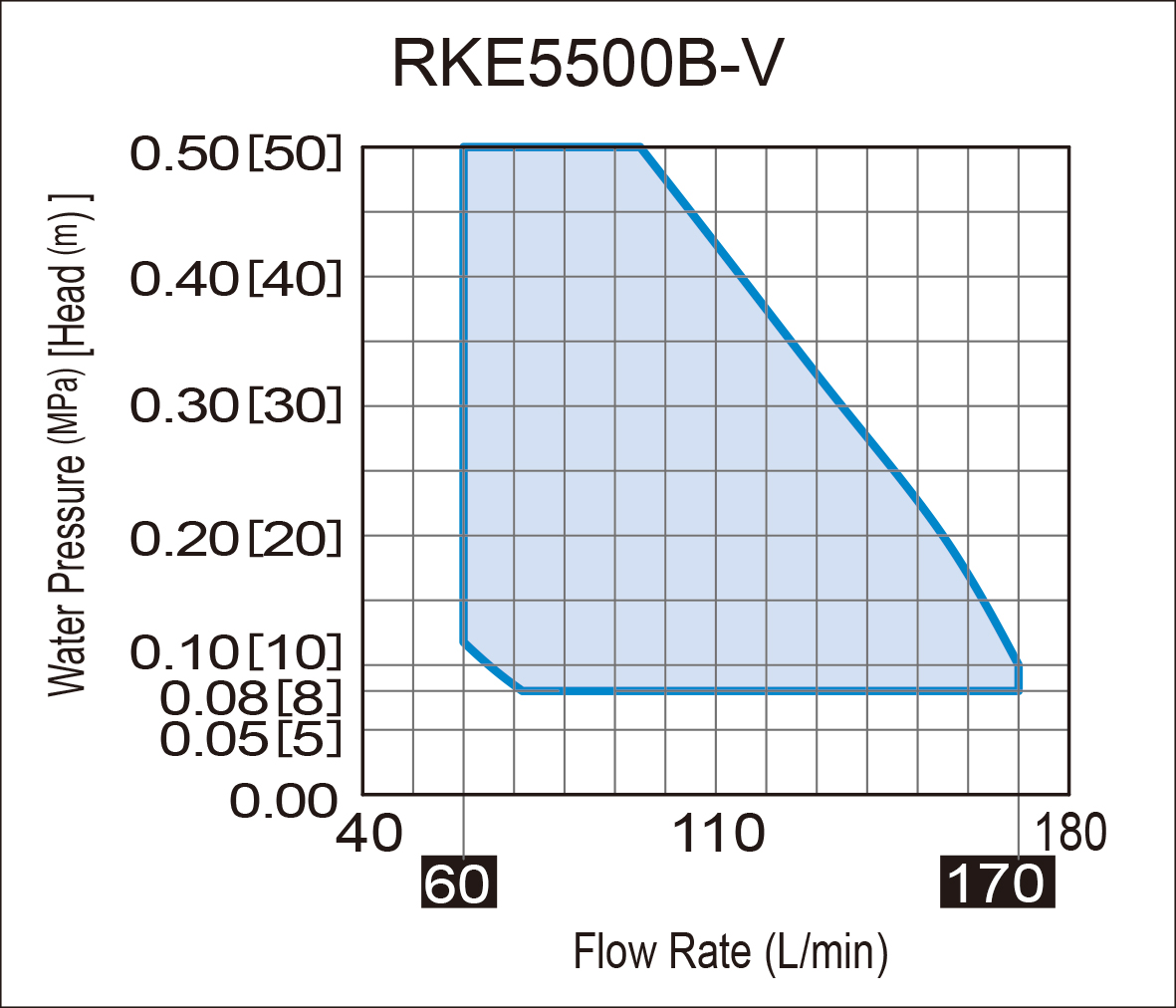

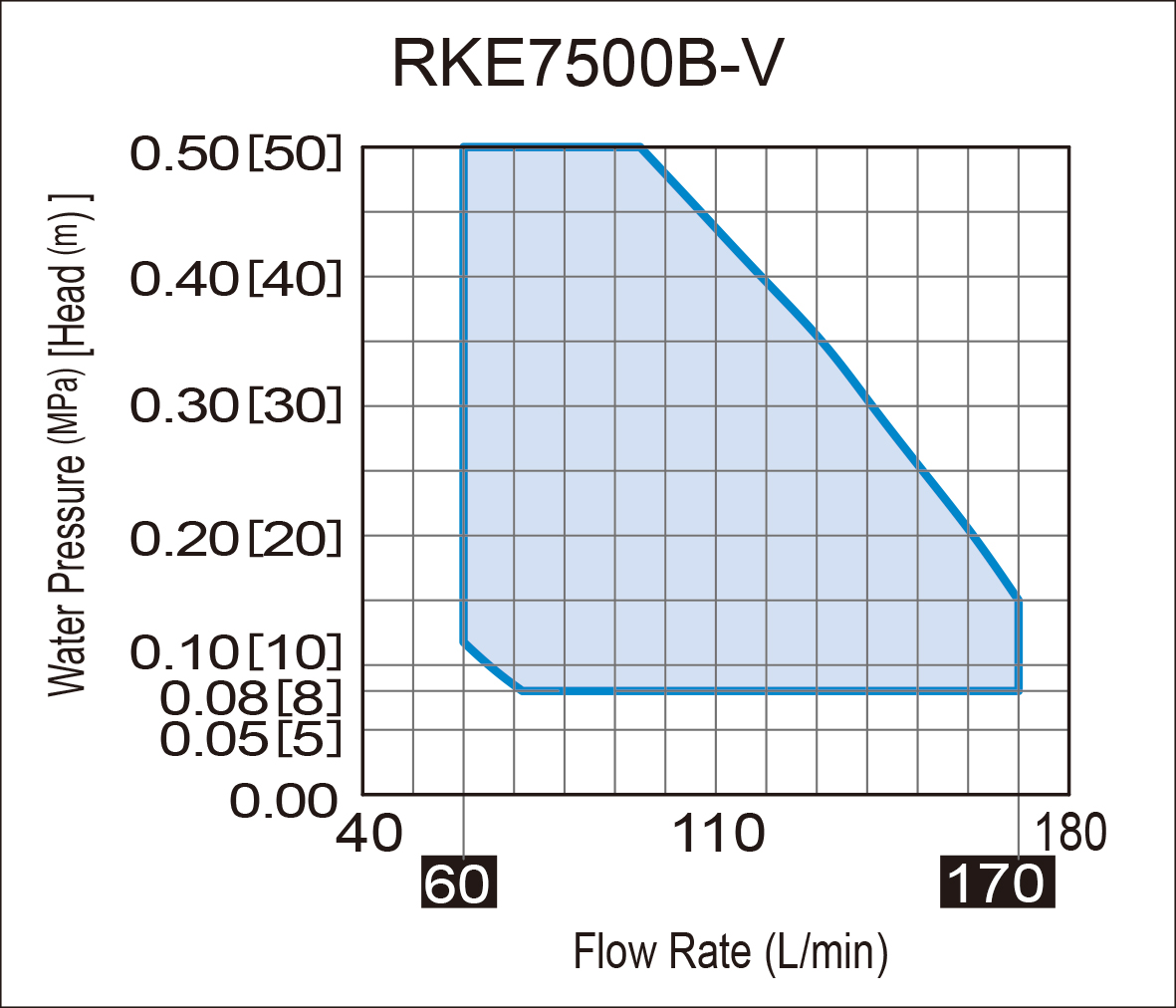

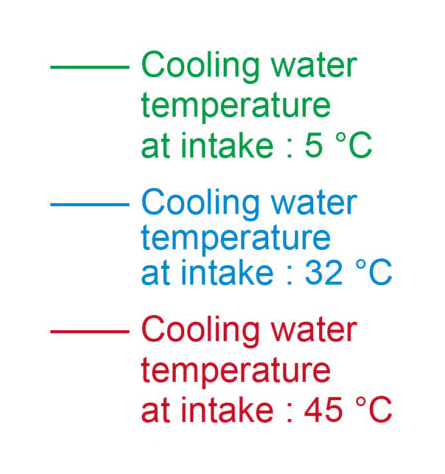

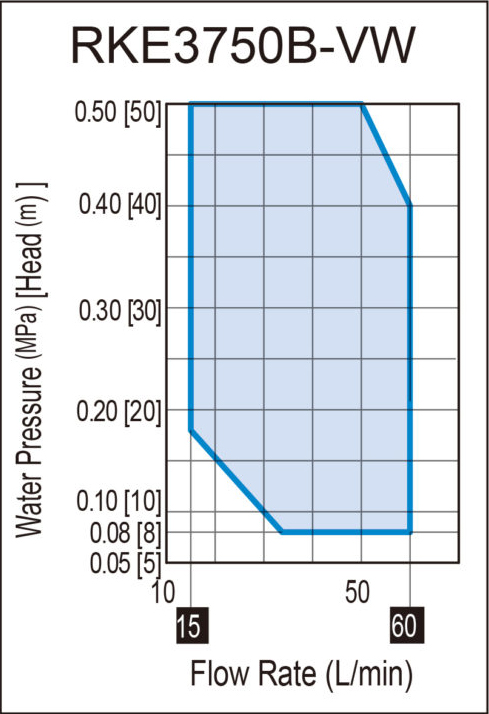

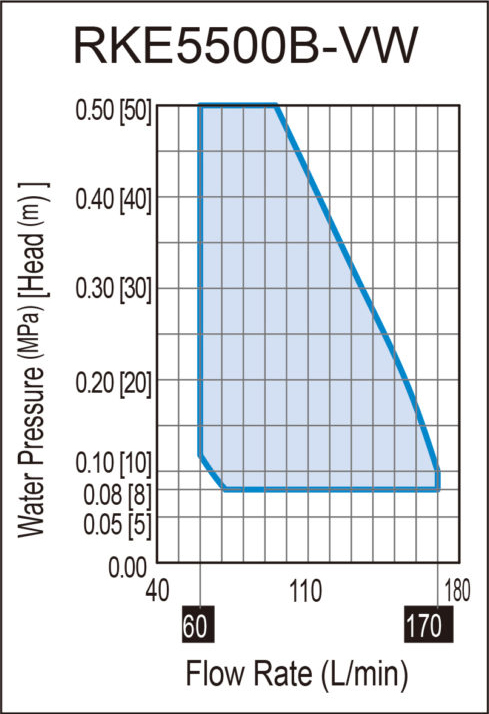

Cooling Capacity Curve

Chilled Water Flow Rate

* The graph shows the actual measured external flow rate when the bypass valve is closed.

* The inverter changes the frequency, thus changing the flow rate.

* The hatched area indicates the possible range of adjustment based on frequency changes.

* The flow rate and pressure indicated are the values shown on the chiller display.

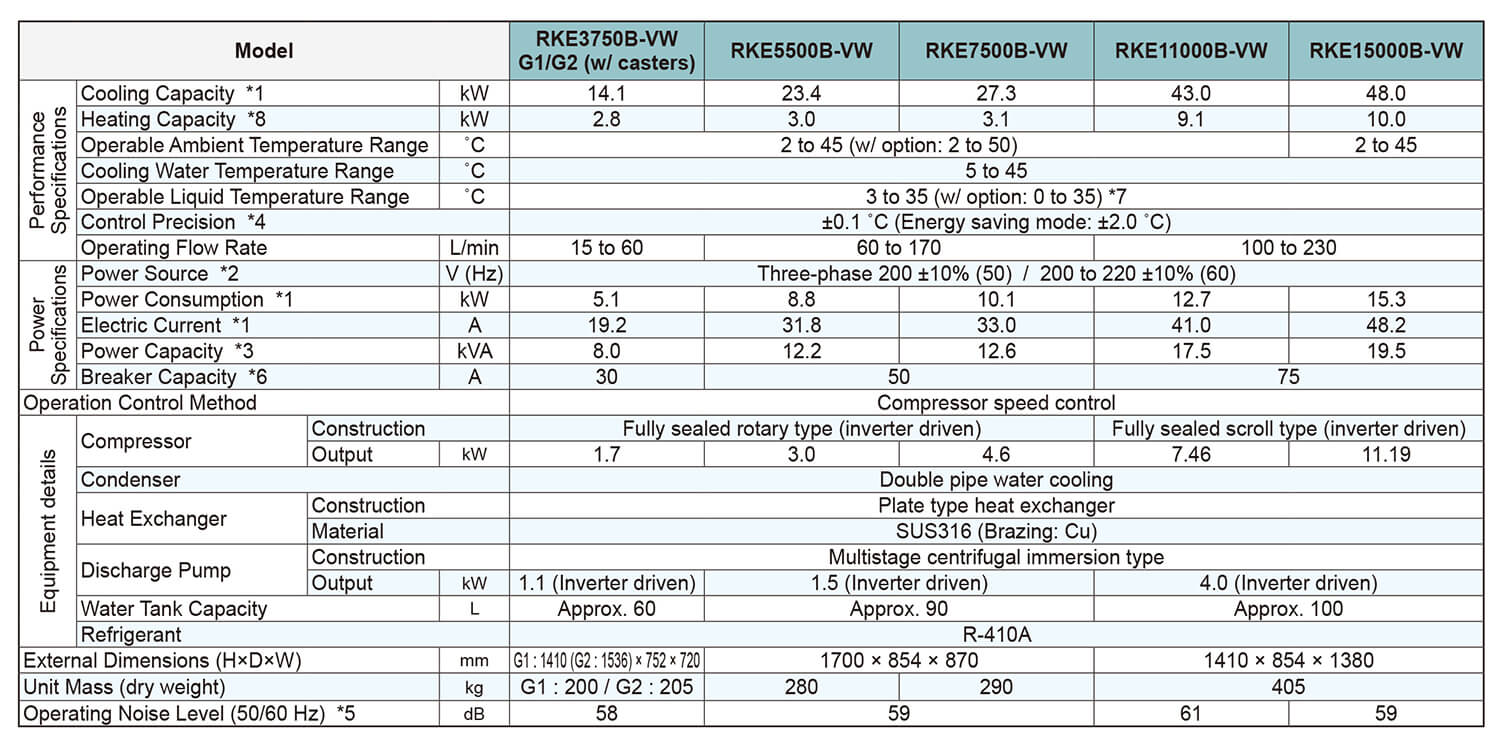

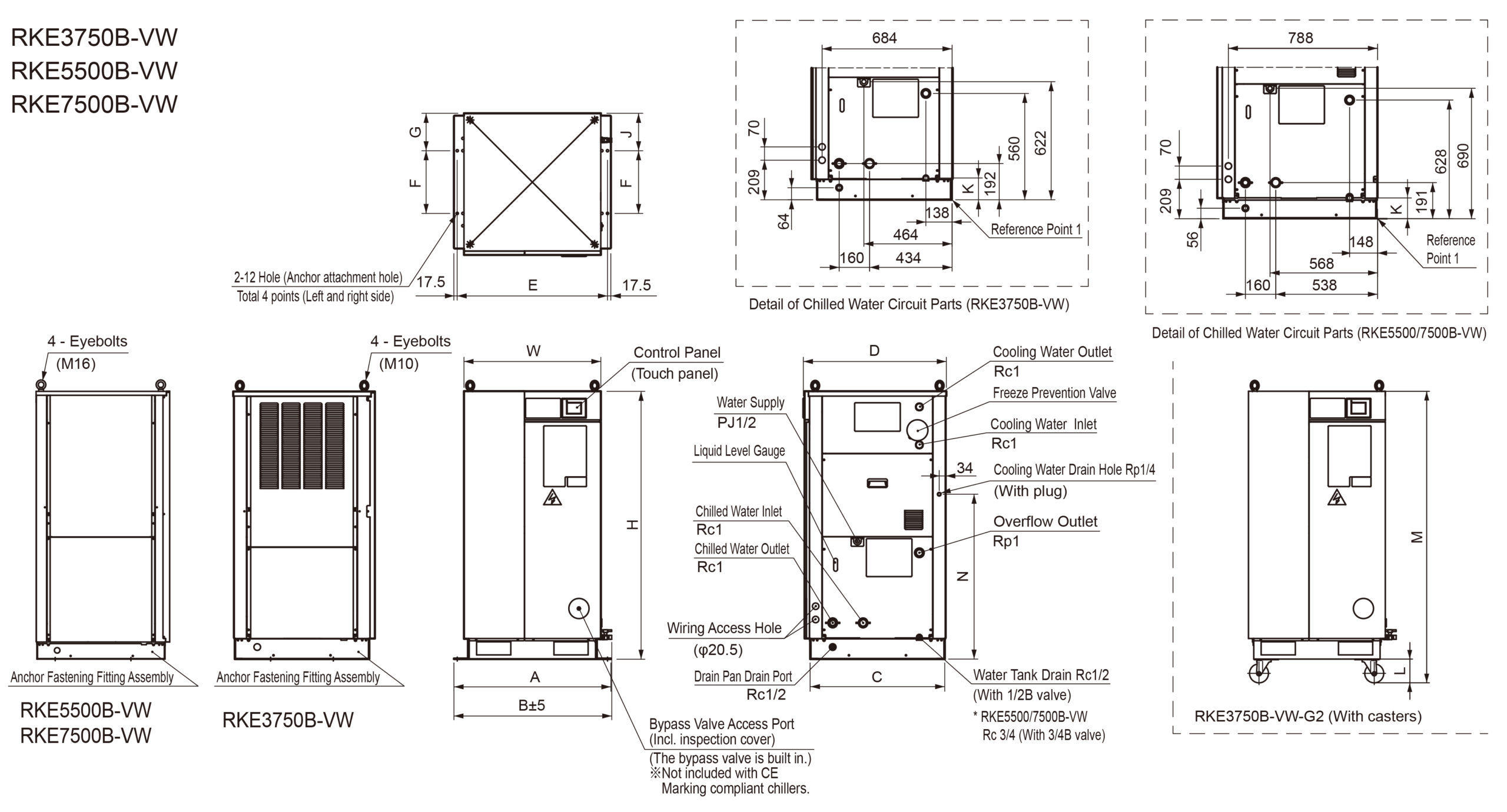

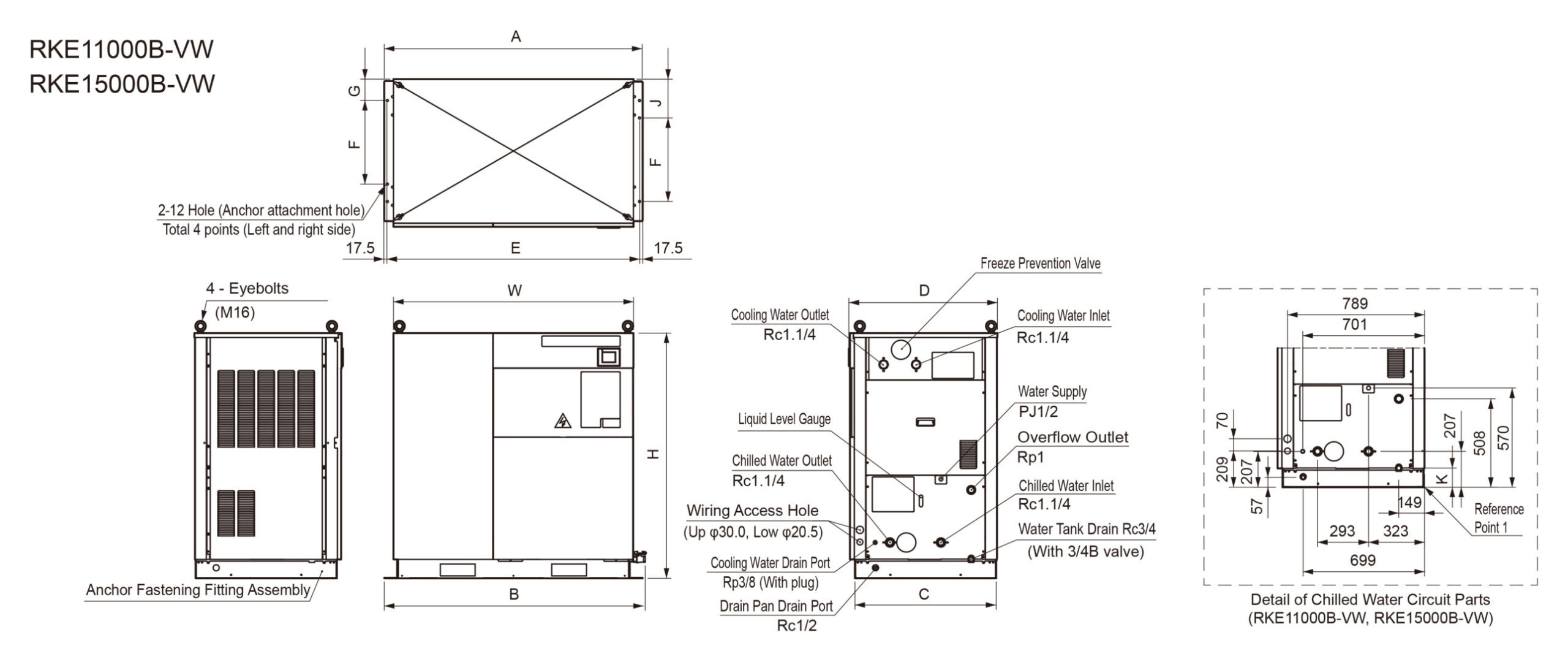

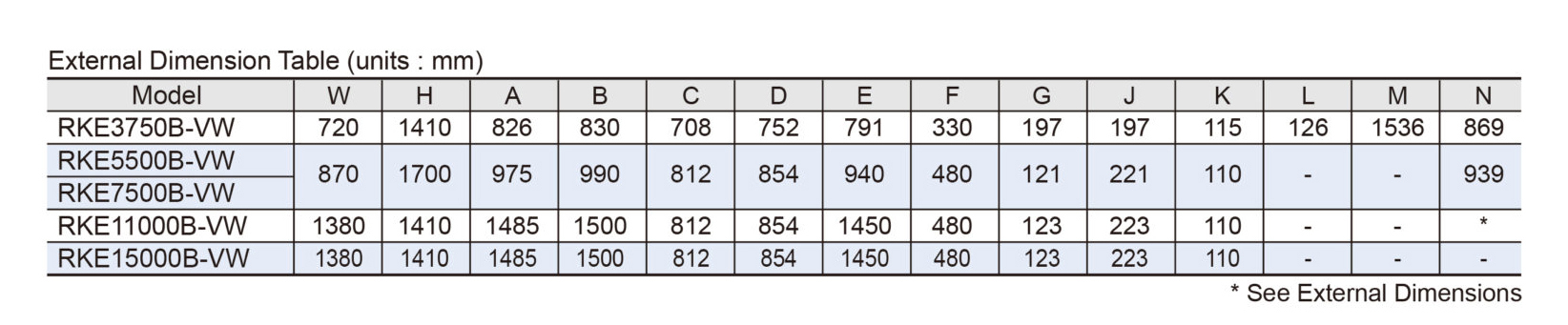

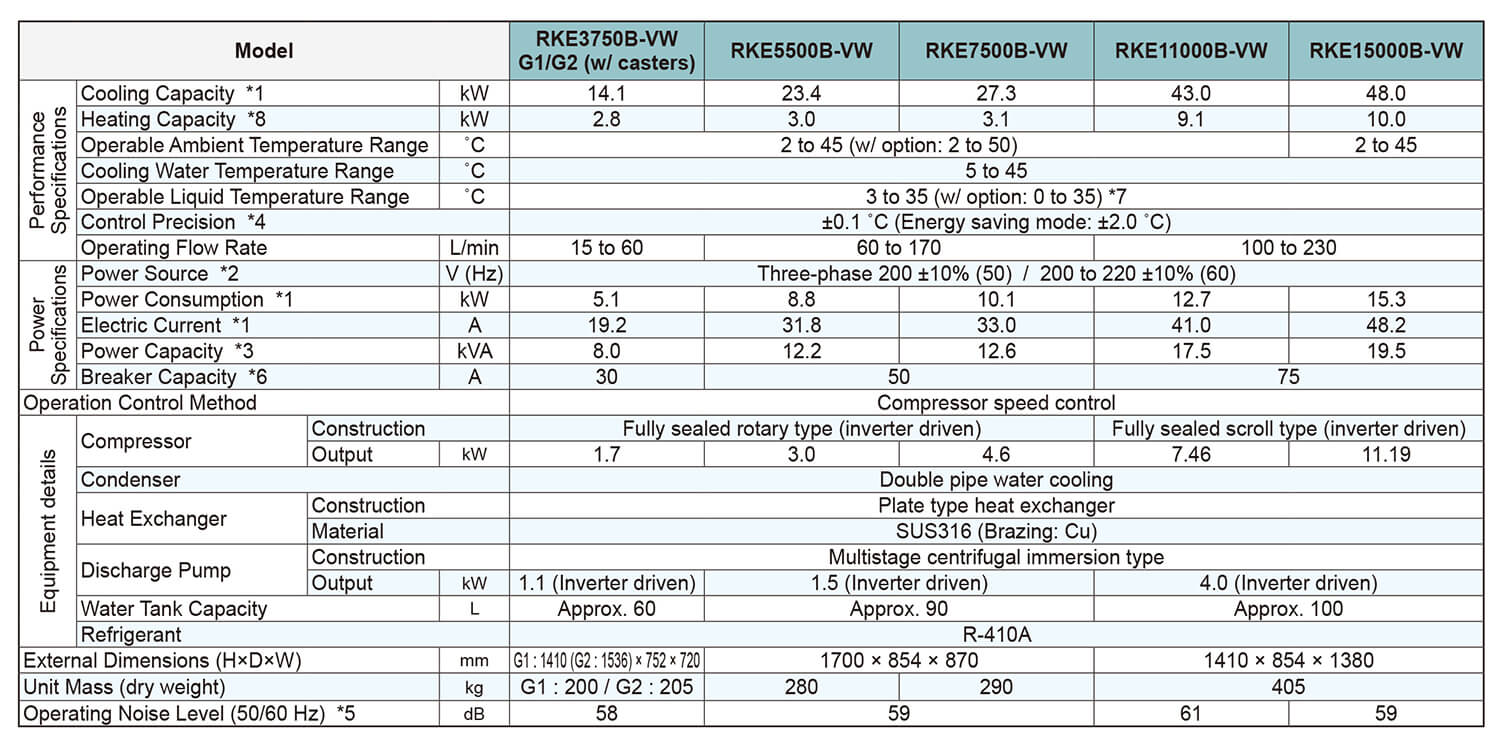

[Water Cooled] Specifications

*1 When operating under these conditions: chilled water temperature is 20 °C, the cooling water temperature is 32 °C, and the ambient temperature is 32 °C. Cooling capacity is at least 95% of listed figures.

*2 Only during startup, and will differ depending on the ambient temperature and cooling water temperature.

*3 Continuous current load fluctuation within ±10%, and with stable ambient temperature (cooling water temperature) and power supply, etc. Does not include starting times or when the cooling load is too small, in which case the compressor may cycle on and off.

*4 The source voltage phase unbalance should be within ±3%.

*5 The figure noted is when the product is operating at the highest capacity within its normal operating range.

*6 Comes standard with a built-in multi-purpose overload and short circuit protection earth leakage breaker.

*7 Operating noise levels are from a position of 1 m in front of the product and at a height of 1 m.

*8 If operating with a set temperature down to 0 to 3 °C, then use a 30% to 40% solution of industrial-use ethylene glycol.

Note 1: The recommended liquid (chilled water) for use in this product is clean water or a 30% to 40% solution of industrial-use ethylene glycol. However, when doing so, there will be a 10% drop in cooling capacity. Alternatively, if conditioned water is used, then it should have an electrical conductivity of at least 1 µS/cm.

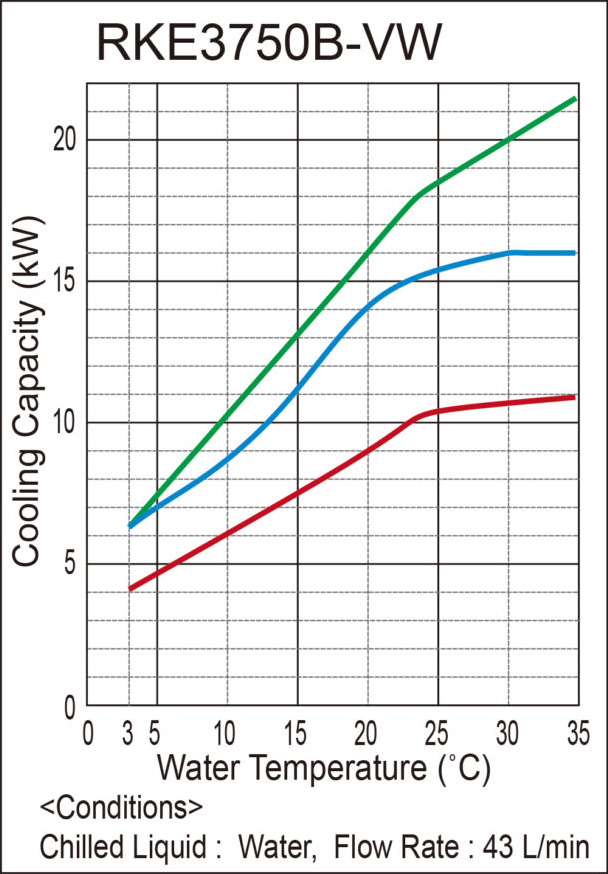

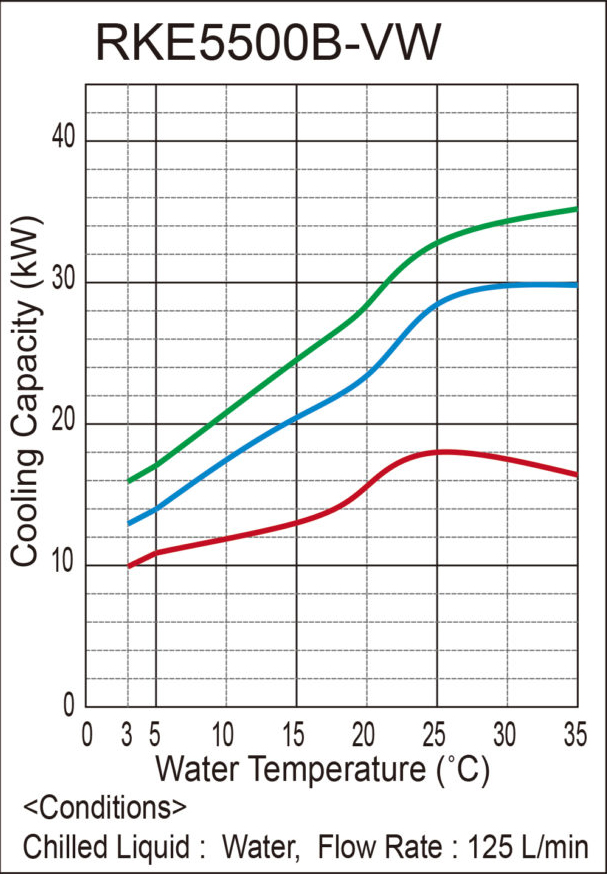

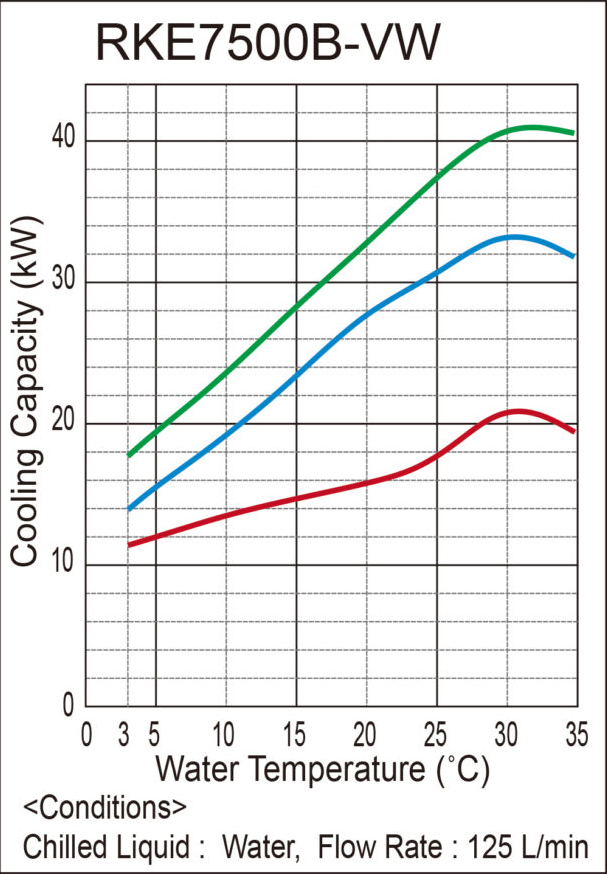

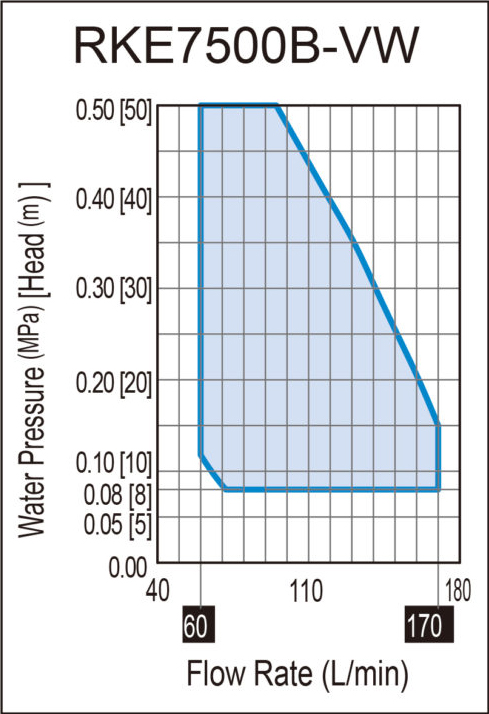

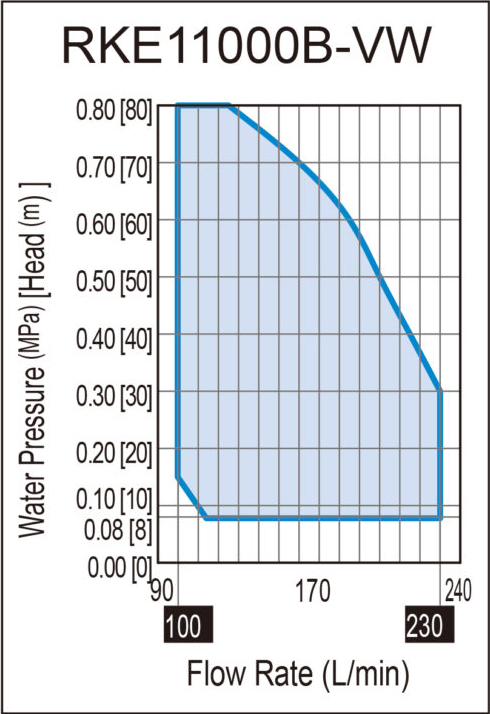

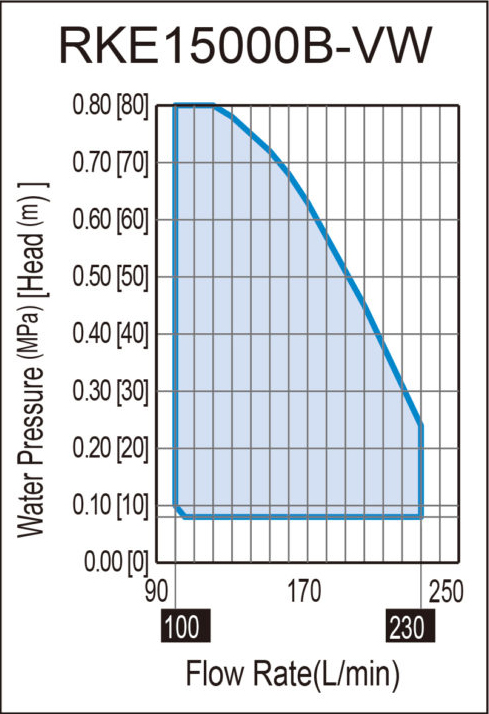

[Water Cooled] Performance Specifications

Cooling Capacity Curve

* The required cooling water flow rate will depend on the water temperature.

* The required flow rate shown in the graph must be maintained.

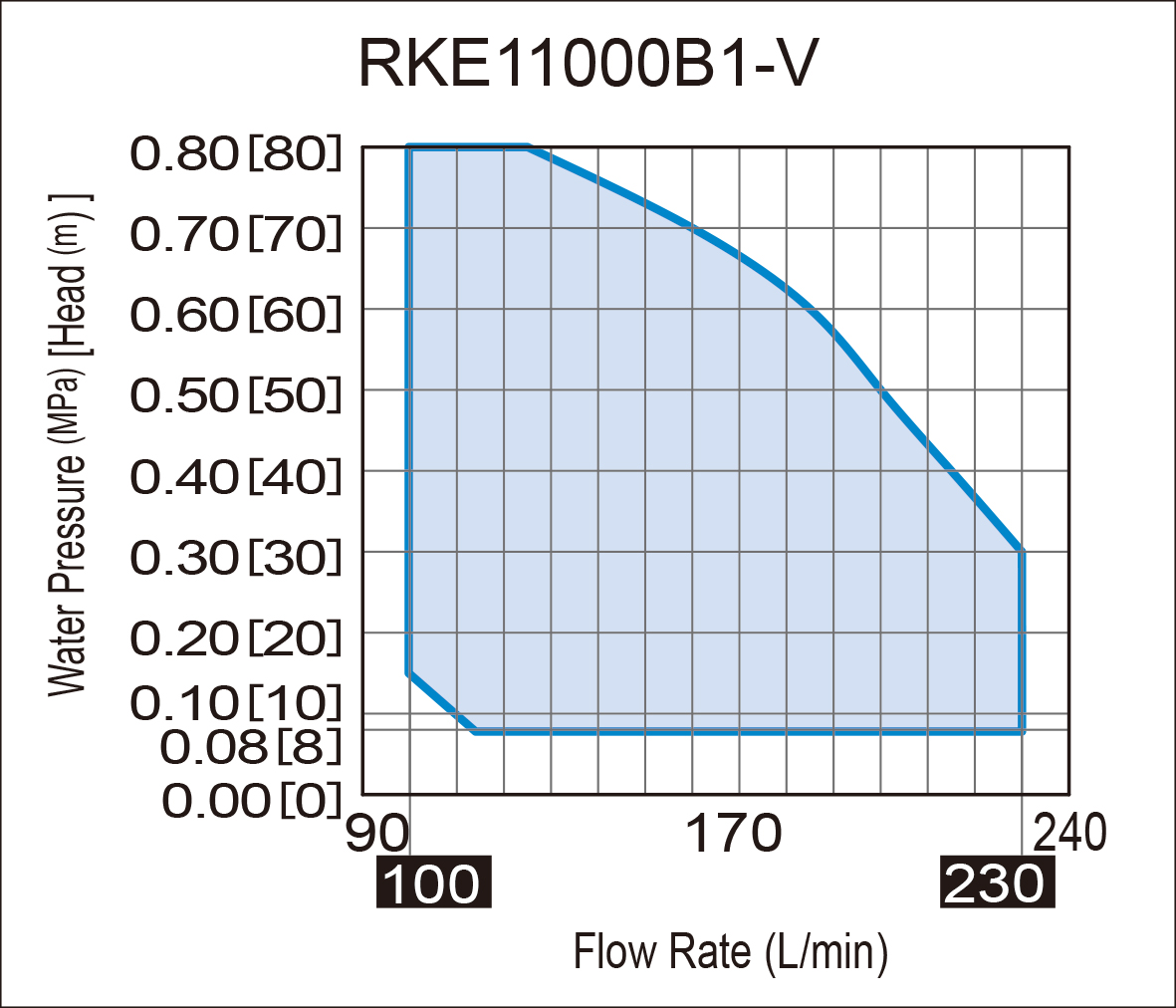

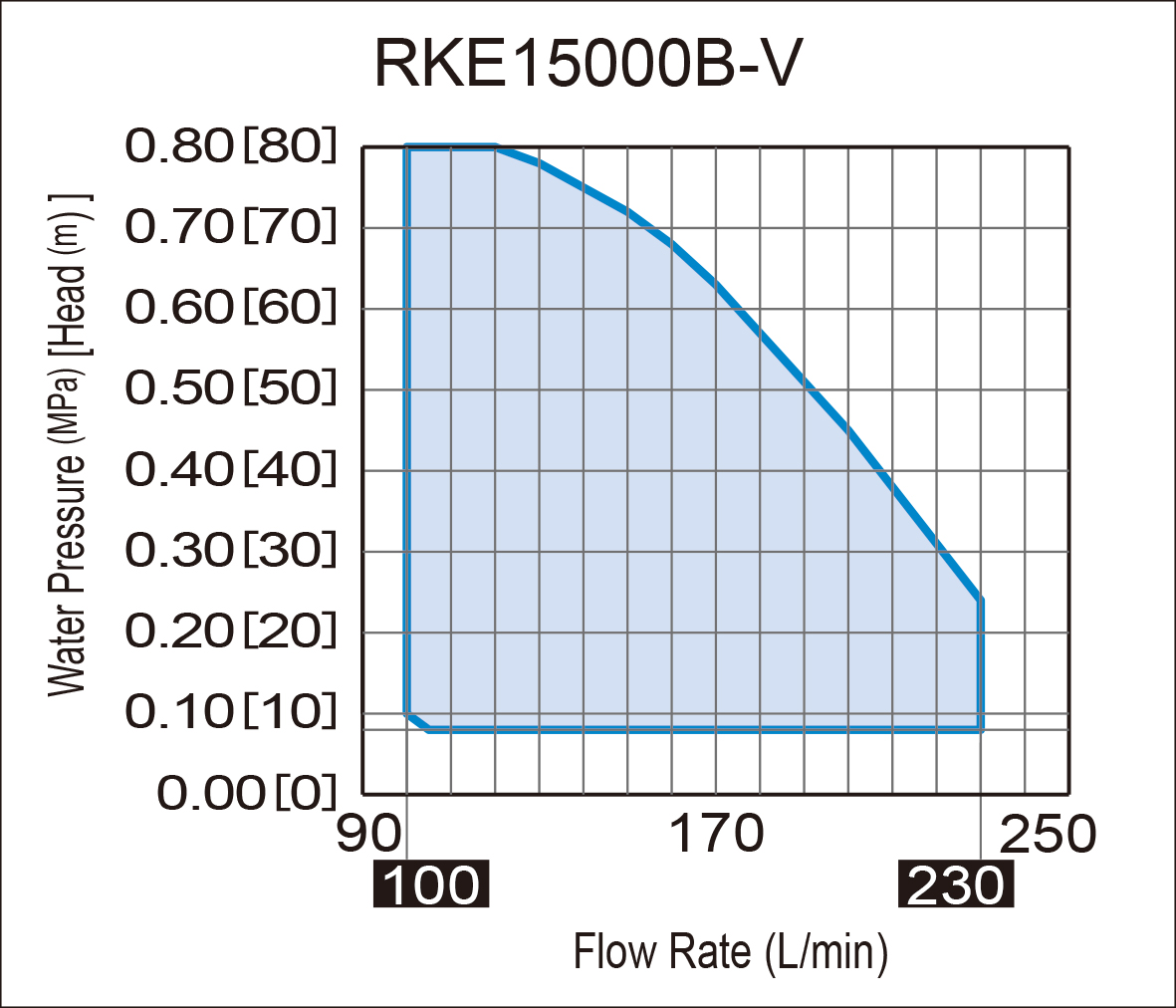

Chilled Water Flow Rate

* The graph shows the actual measured external flow rate when the bypass valve is closed.

* The inverter changes the frequency, thus changing the flow rate.

* The hatched area indicates the possible range of adjustment based on frequency changes.

* The flow rate and pressure indicated are the values shown on the chiller display.

Cooling Water Flow Rate (For water cooled condenser)

* Actual cooling water flow rate will depend on the water temperature.

* Ensure the required quantity of water as shown in the graphs.

![[Air Cooled] External Dimensions](https://www.orionmachineryna.com/wp/wp-content/uploads/2020/03/RKE-B_dimensions01.jpg)