Features

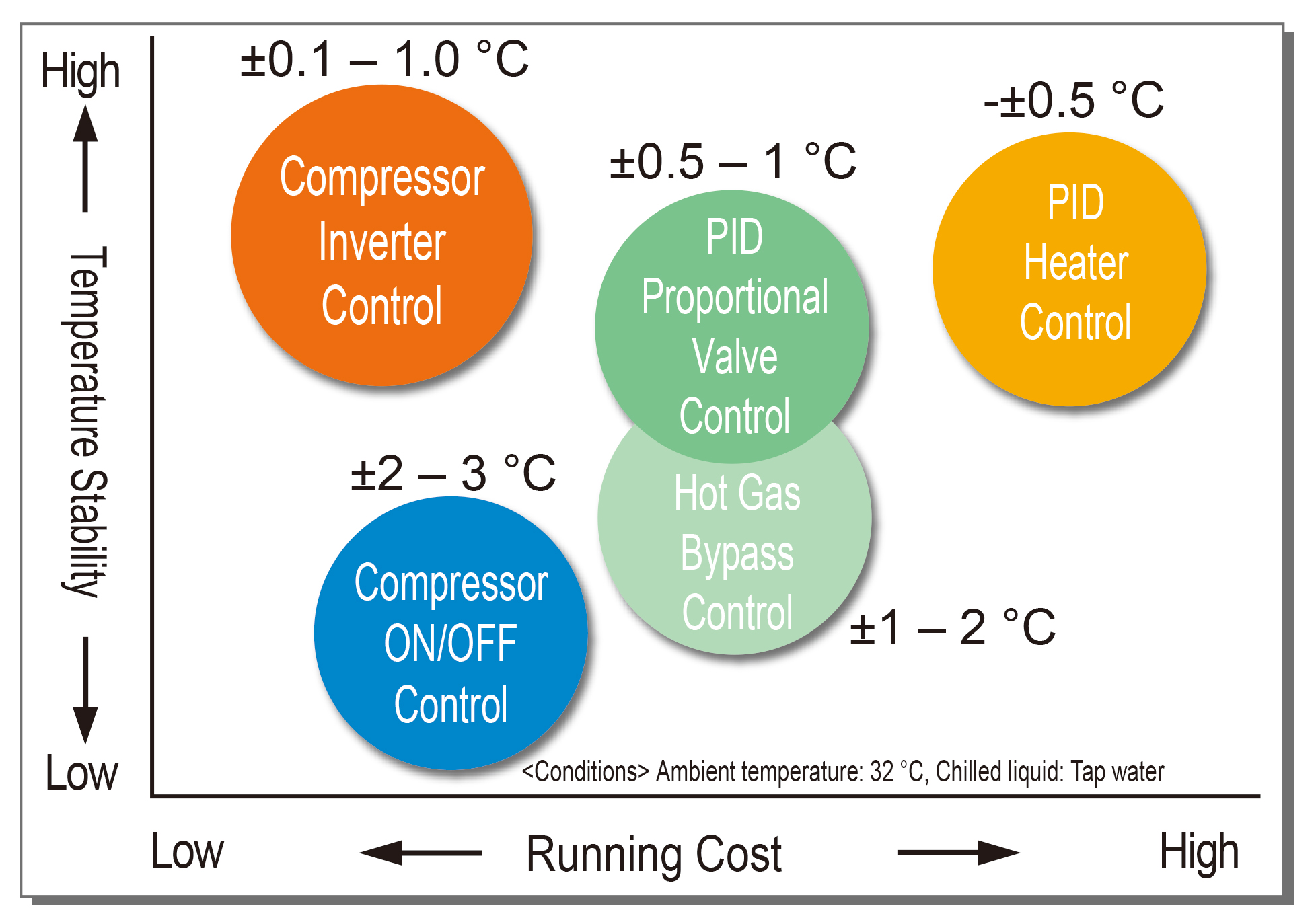

Making normally opposing technologies of energy-saving and high-precision work together.

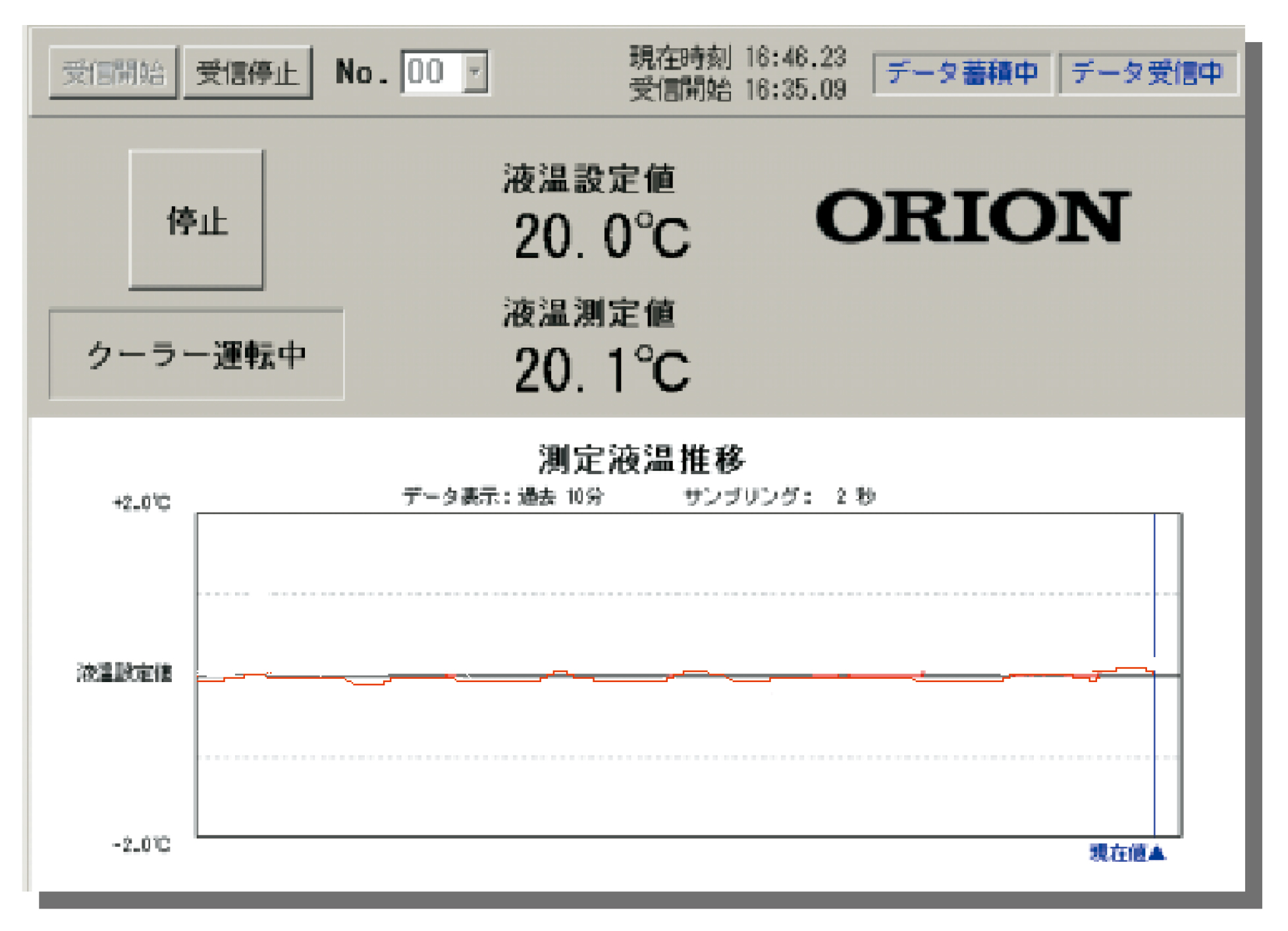

Our inverter controlled compressor responds to fluctuating workloads linearly, achieving high precision control while using the least amount of energy. Also, thanks to ORION's original capacity control technology, high precision temperature control can be maintained even during low load situations that are normally difficult to deal with.

(User can choose between "High-Precision" and "Energy-Saving" modes in response to low-load conditions.)

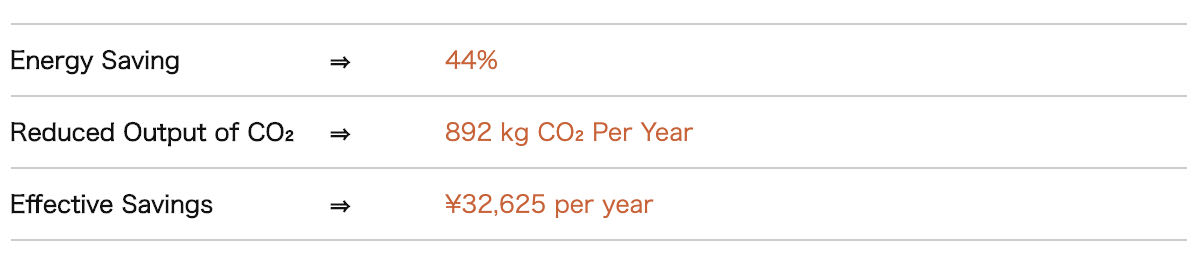

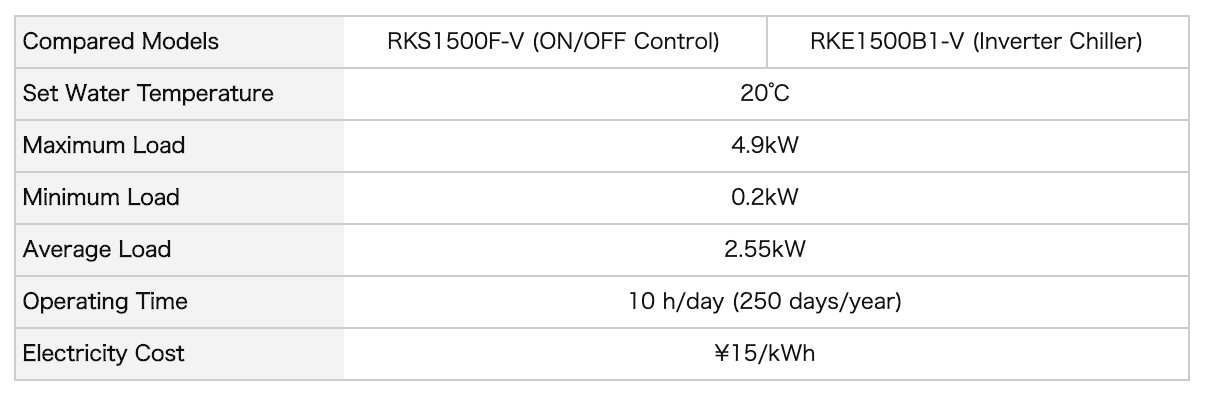

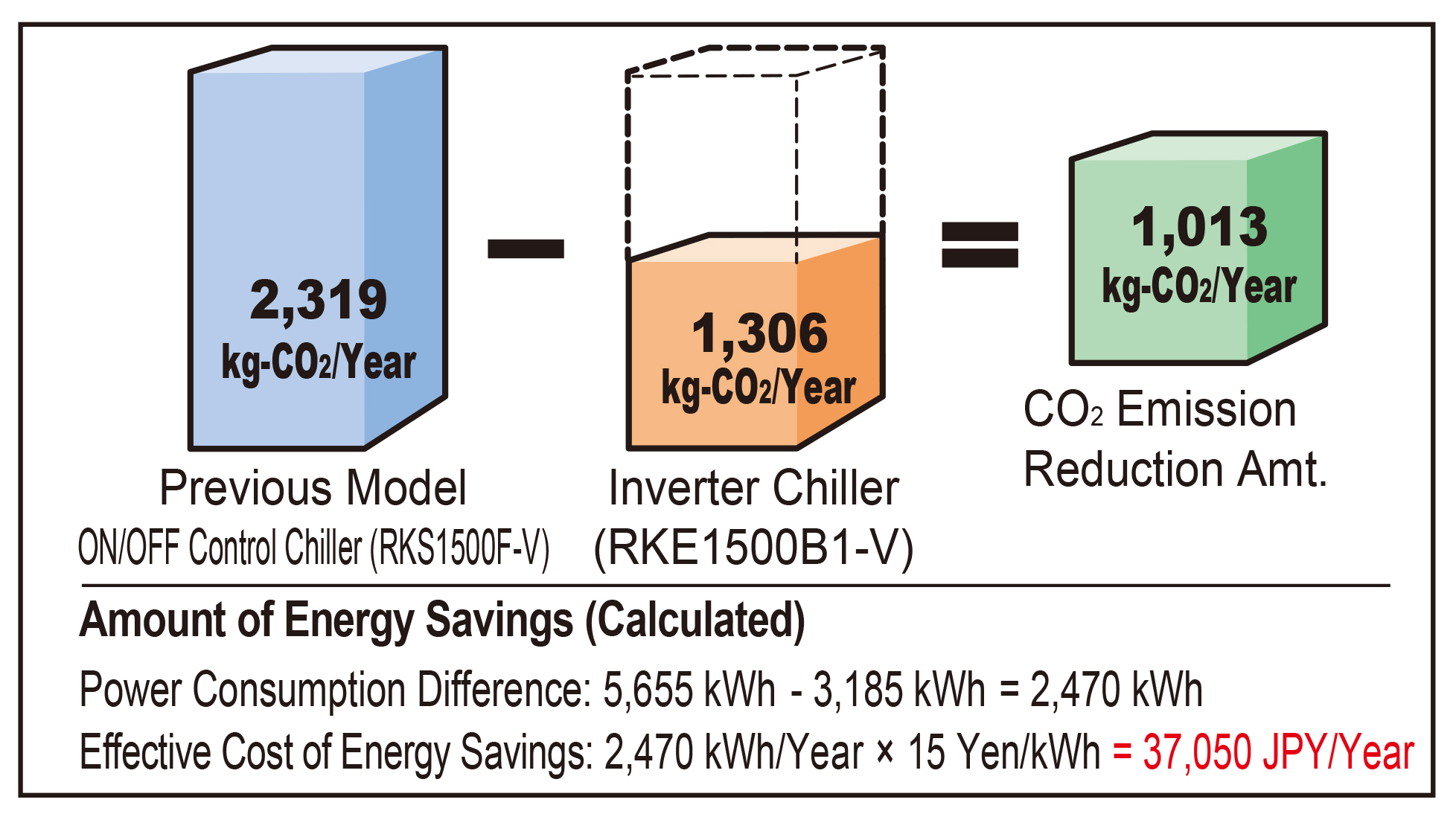

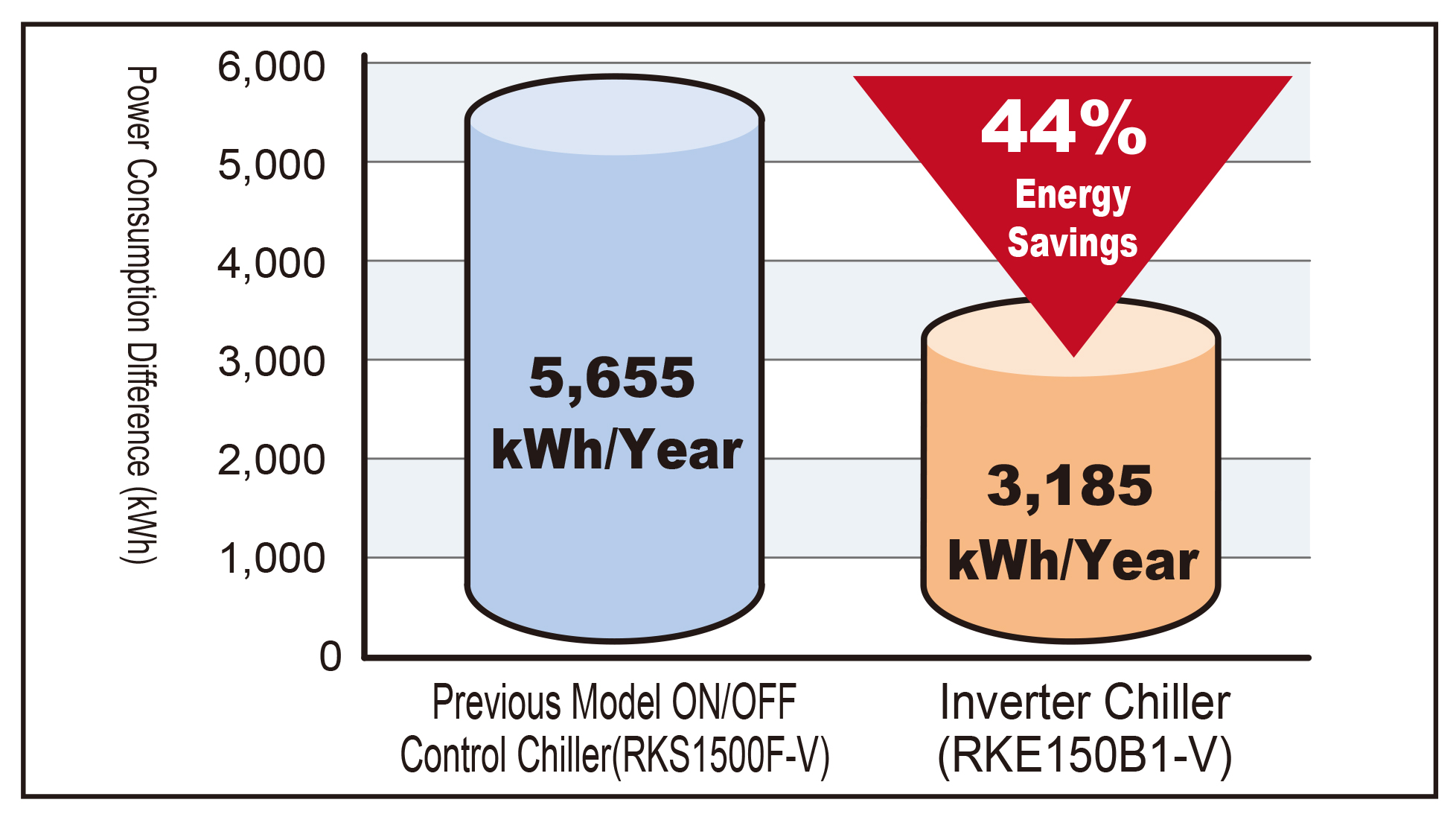

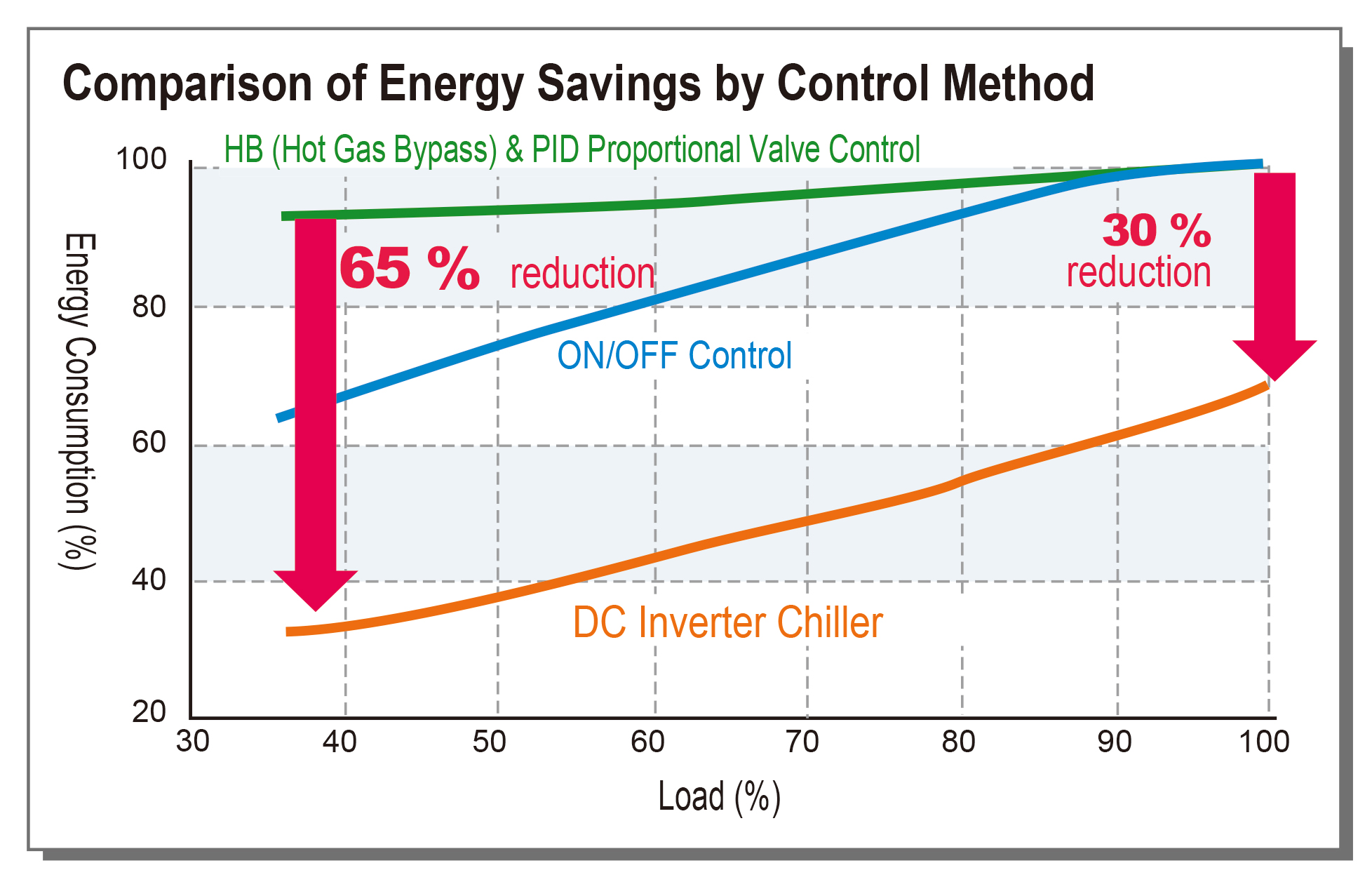

As much as 65% Energy Savings Possible

Even compared with power saving ON/OFF type chillers, our DC Inverter control models offer energy savings of 30% at full load. A maximum 65% reduction in energy is possible when compared with temperature-stability-focused hot gas bypass types or proportional valve PID controlled chillers.

±0.1℃* High Precision Control

Adaptable to various applications that require high precision operation by using high-level temperature management.

Its extreme versatility makes it suitable for a wide range of applications, including precision production-use lasers, semiconductor manufacturing, analytical devices, and many others.

* When the load and ambient temperature are stable.

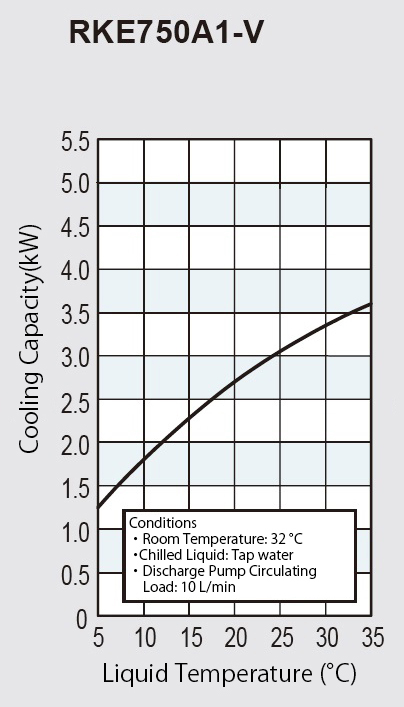

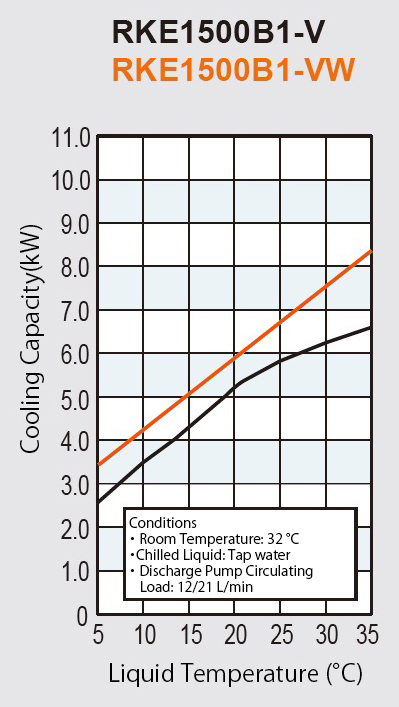

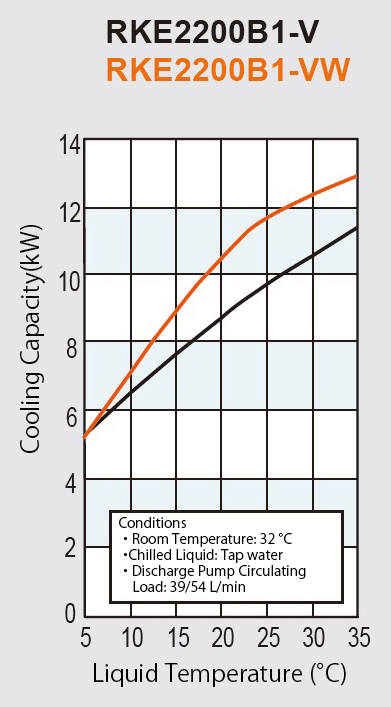

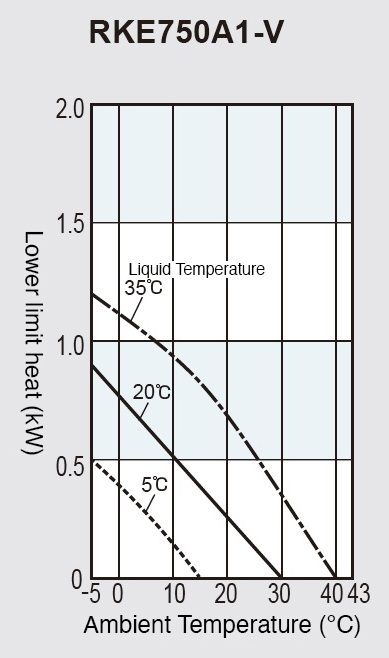

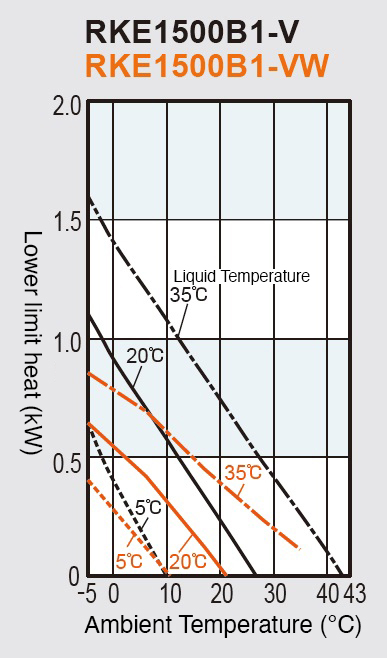

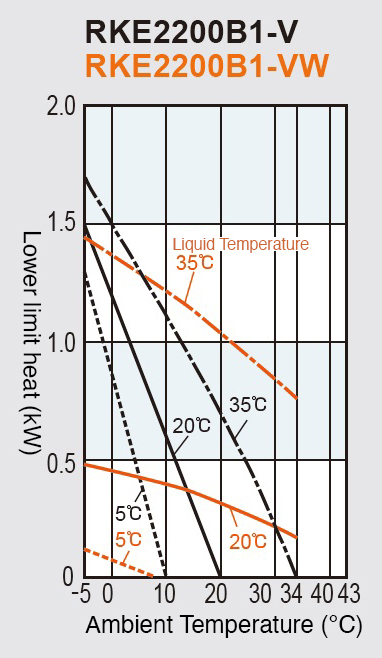

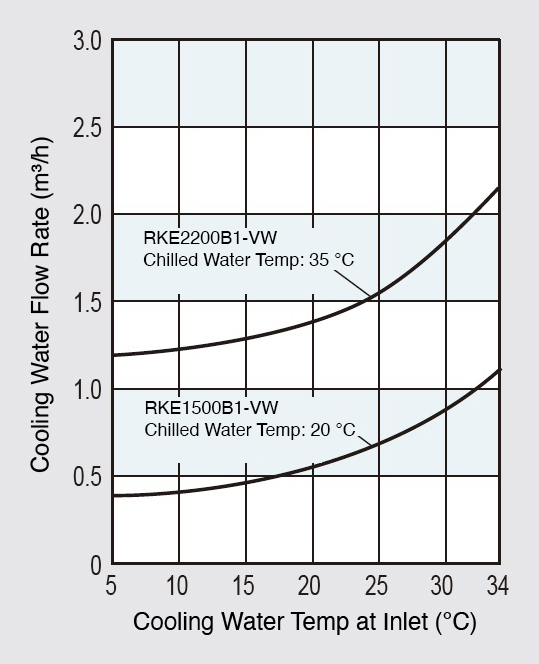

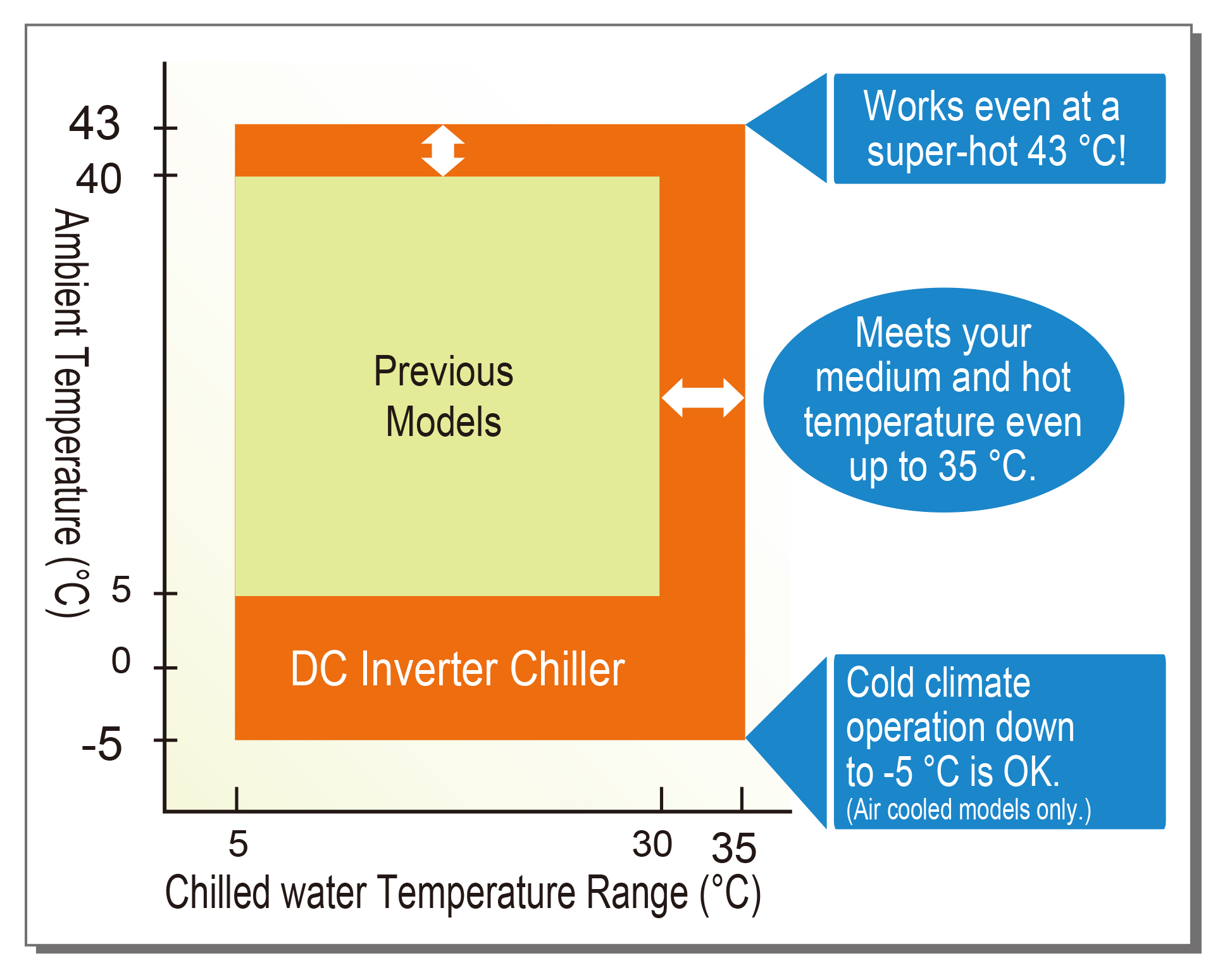

Wide Range Achieved

Fluid Temp. Control Range of 5 to 35 ℃ allows for wide-ranging applications. High temperature operation possible for piping condensation prevention, etc. Works in an increased range of ambient temperatures*from –5 to +43 ℃. (Water cooled types from +2 ℃.)This means our chiller can do its job under even harsher working conditions.

* If the ambient temperature could possibly fall down to 5 ℃ or lower, then measures should be taken to ensure that external piping does not freeze.

Built for Improved Ease of Use