Features

Made Even Easier to Use! Simple and Safe Design Points Shared with all RKS J(M) Series Models

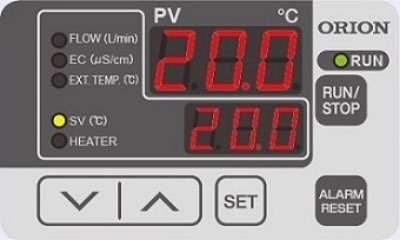

❶Simple and Reliably Designed Controller

❷Large diameter water supply port for easy tank cleaning.

❸Easy-to-check LED-lit water level gauge.

❹Comes standard with a filter to help prevent clogging!

Simple and Reliably Designed Controller

Easy operation with just the press of a button. Error code display gives important information about the alarm. Allows for quick recovery after an issue.

Output Signals

・Operation Signal

・Alarm Signal

・Remote Signal

Operating Mode

・Freeze-Prevention Mode

・Warm Up Mode

・Discharge Pump-Only-Operation

・Automatic recovery after power outage etc.

Large diameter water supply port for easy tank cleaning.

Easy-to-check LED-lit water level gauge.

Φ100 mm large water supply port makes it easy to clean the inside of the tank!

The high capacity tank means less frequent water shortage warnings, less frequent water supplying, and less change in water temperature due to changing loads.

A built-in blue LED-lit water indicator makes it easy to check the water level!

Large Diameter Water Supply Port

Large Diameter Water Supply Port

Makes cleaning the inside of the tank easy!  Easy-to-Check LED-Lit

Easy-to-Check LED-Lit

Water Level Gauge

Comes standard with a filter to help prevent clogging!

Comes standard with a filter to help prevent clogging!

Easy toolless-removable filter design. Filter can be directly cleaned for easy removal of dirt and reduced manpower, adding to operating stability of the chiller.

Optional Equipment

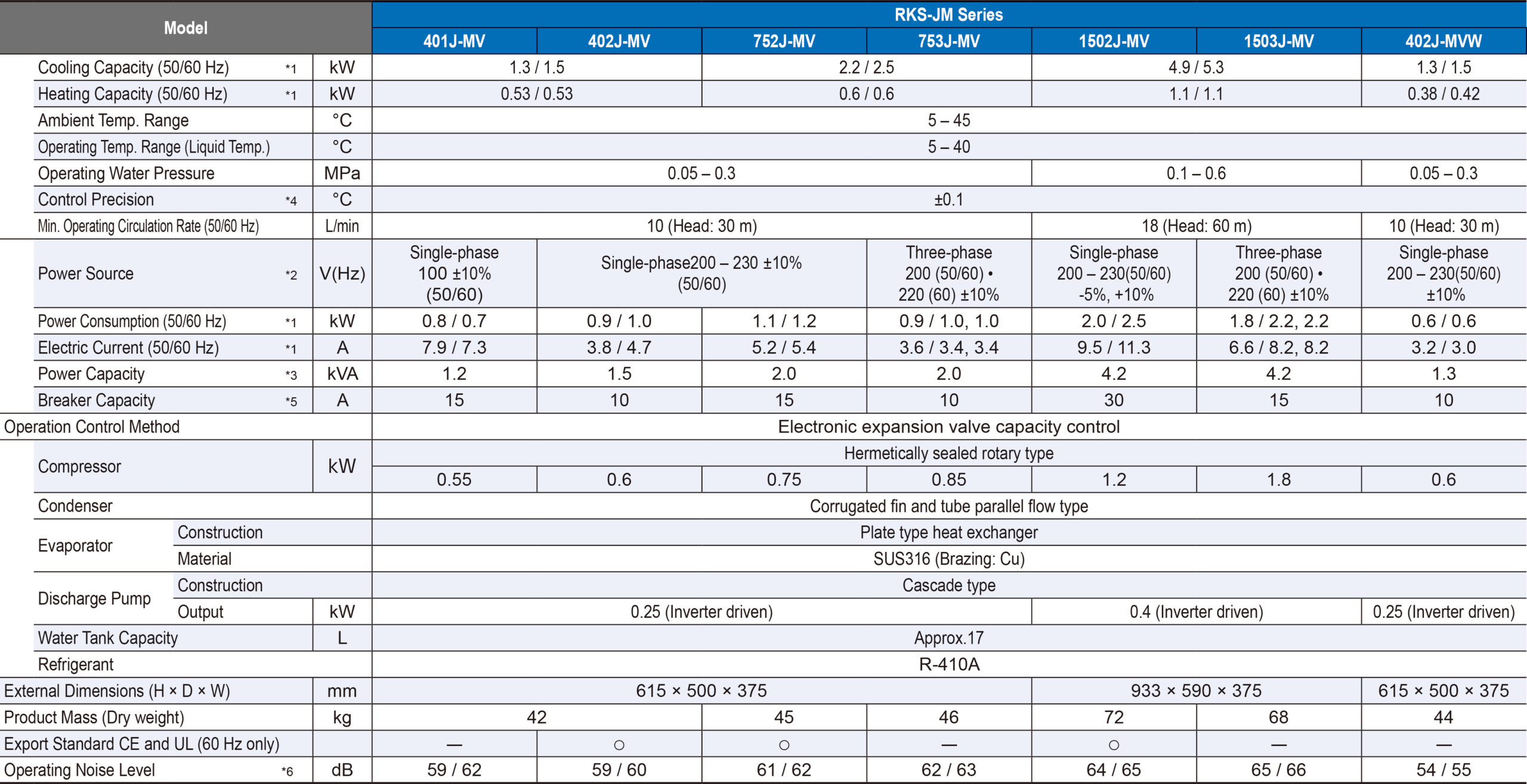

Factory Option Designation Description and Examples

*1 400 class models only.

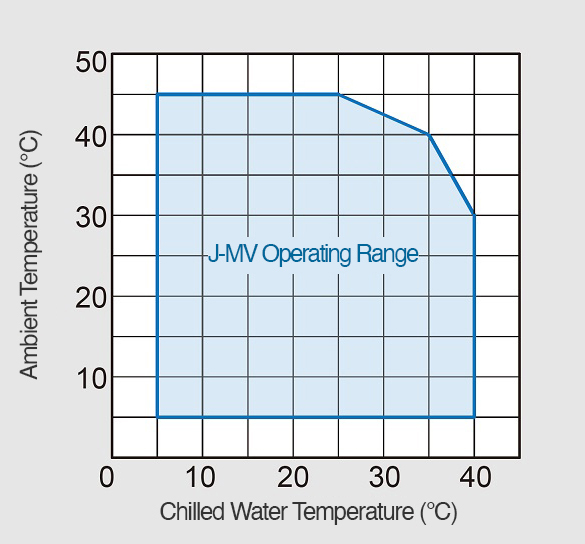

*2 J-MV Series models only.

*3 750 and 1500 class models only.

*4 RKS402J-MV and RKS75□ models only.

Accessories

We provide an abundance of application functionality that matches how you use our equipment.

We have a page that shows all of our accessories. Have a look!

Application

We have a page that highlights applications of the RKS J(M) Series. Have a look!

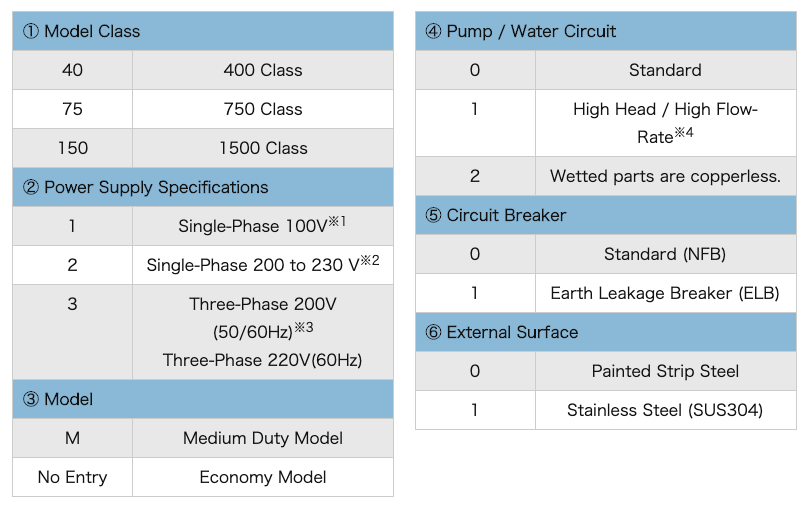

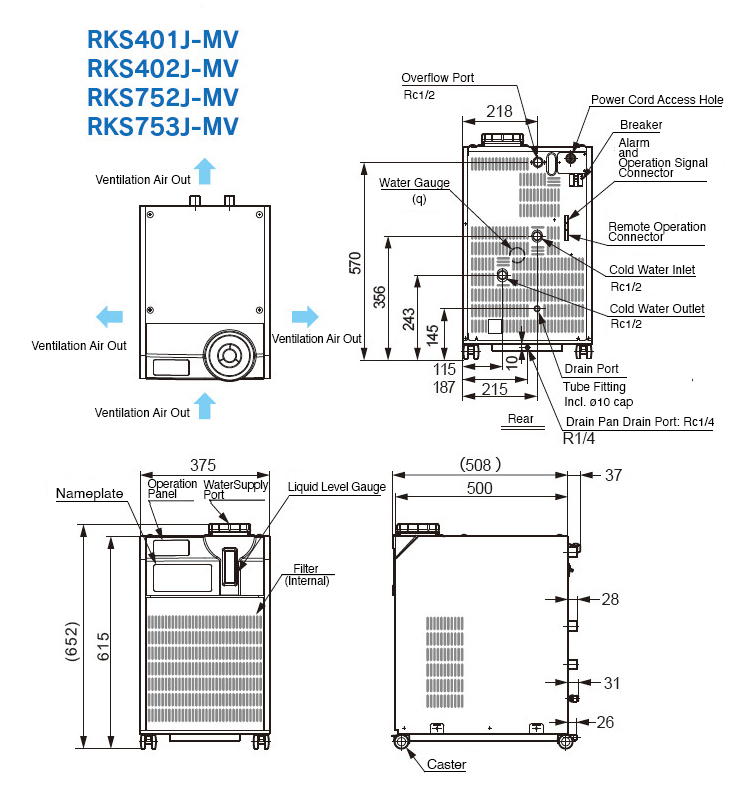

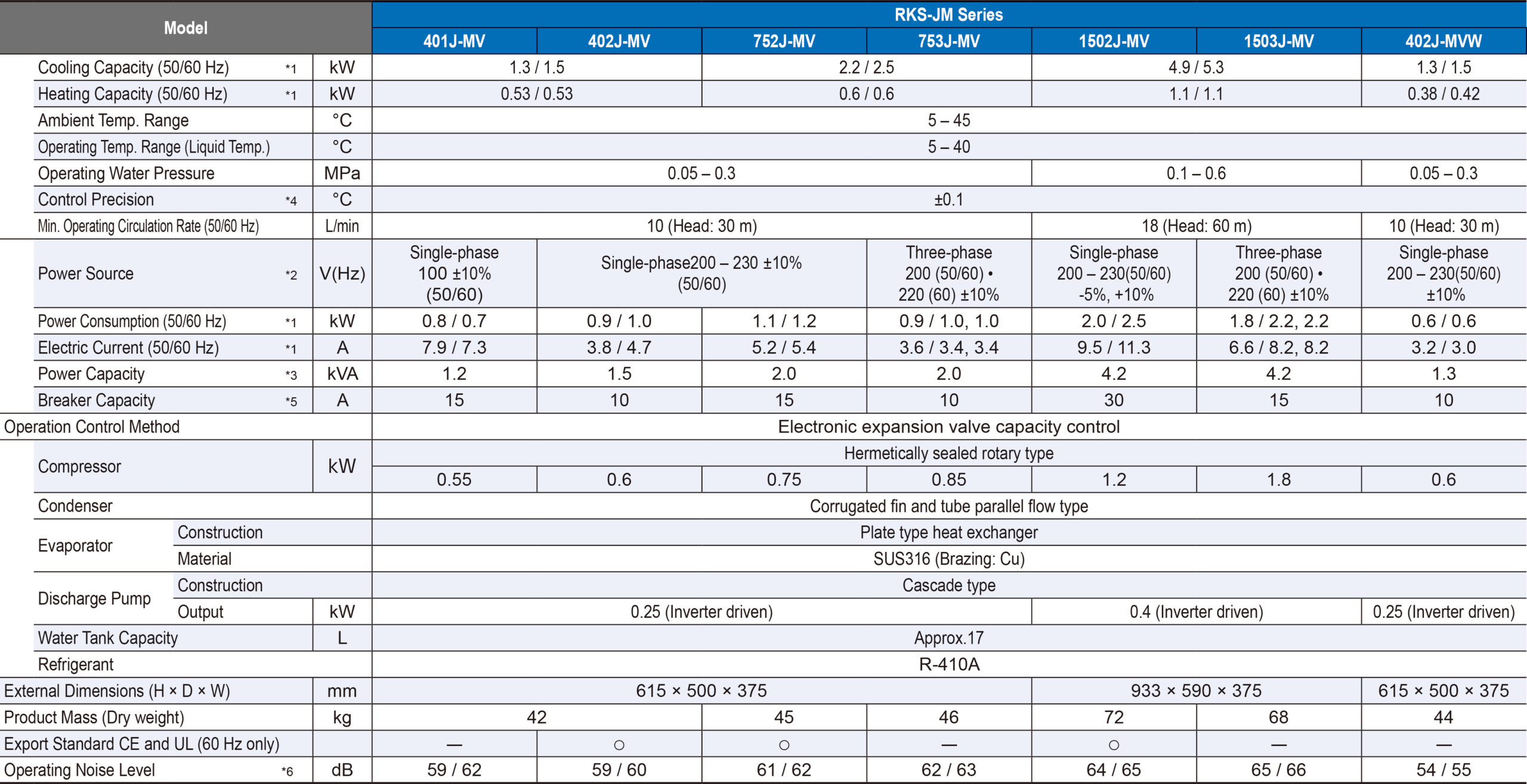

Specifications (Standard Products)

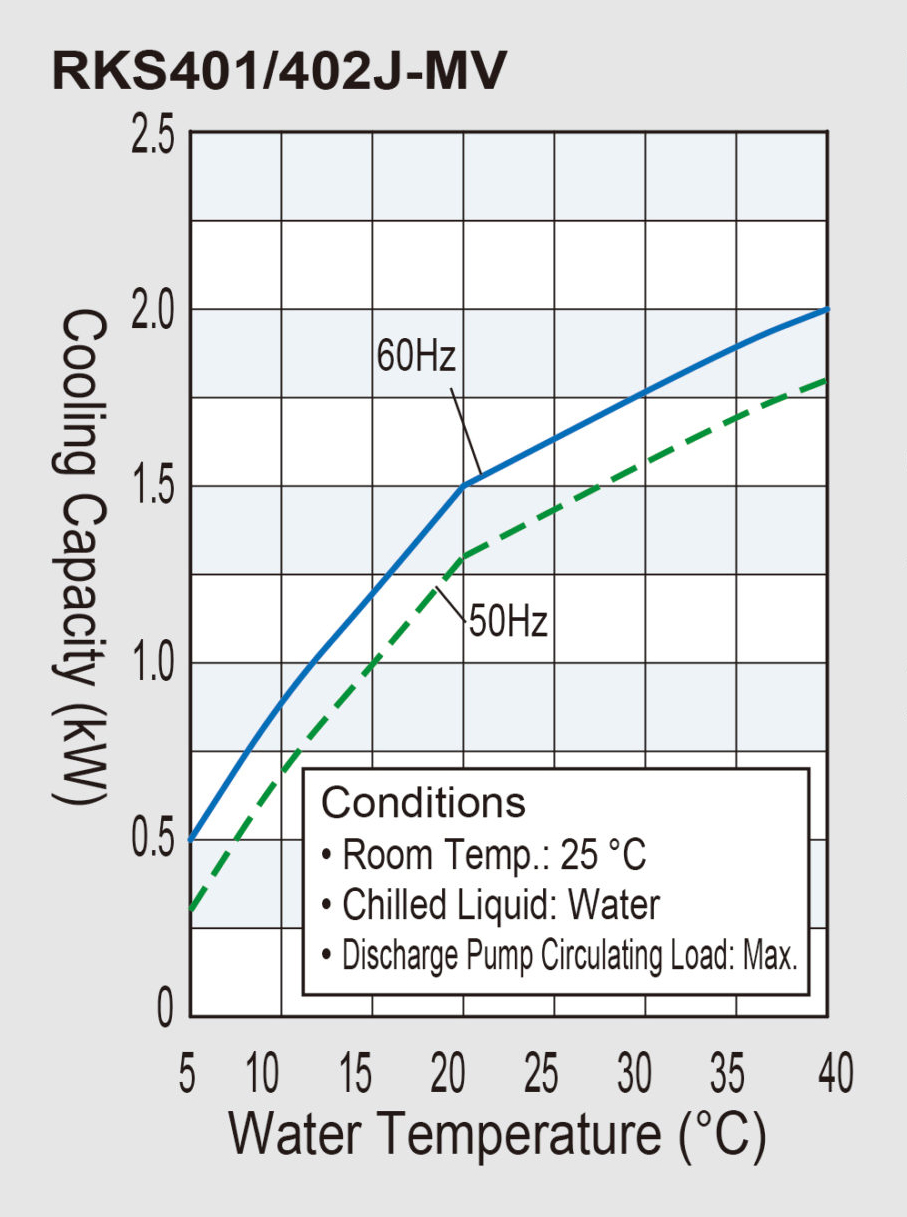

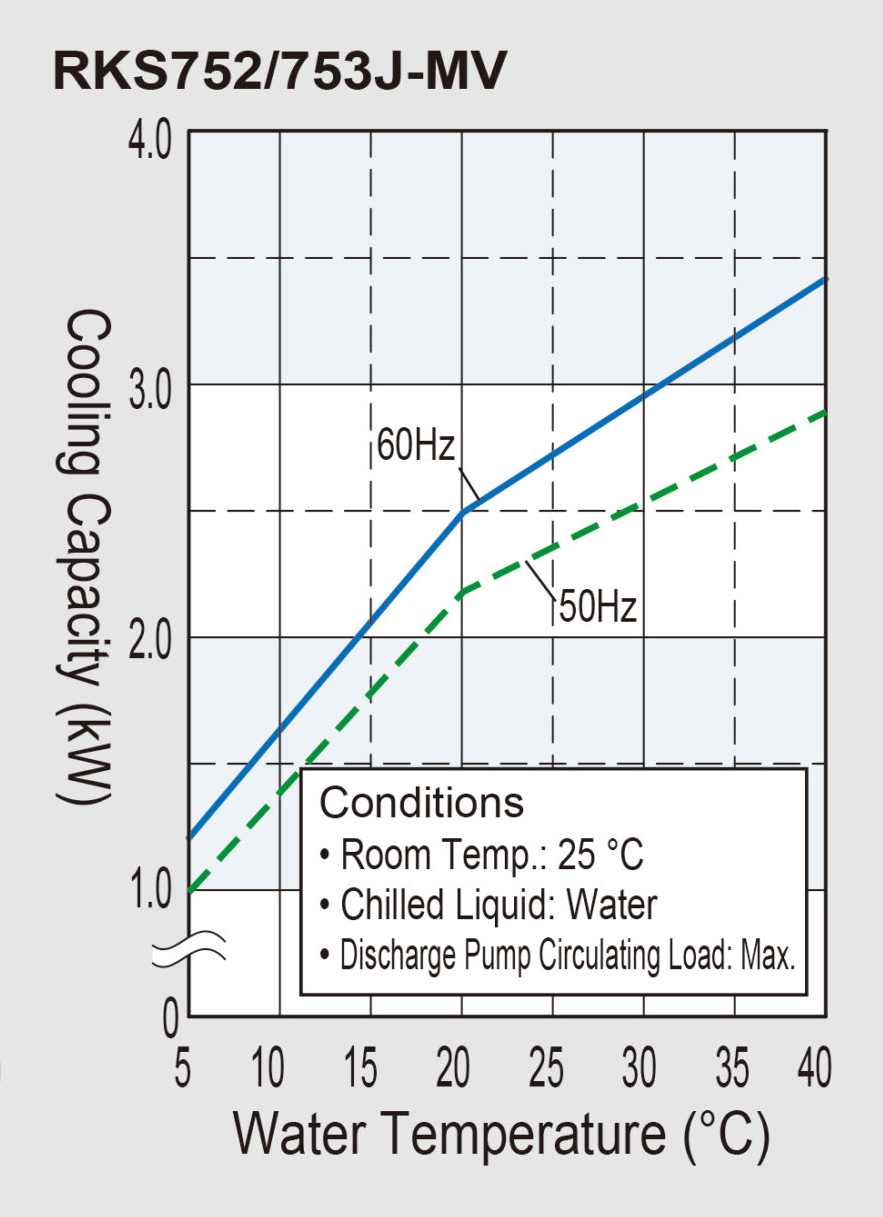

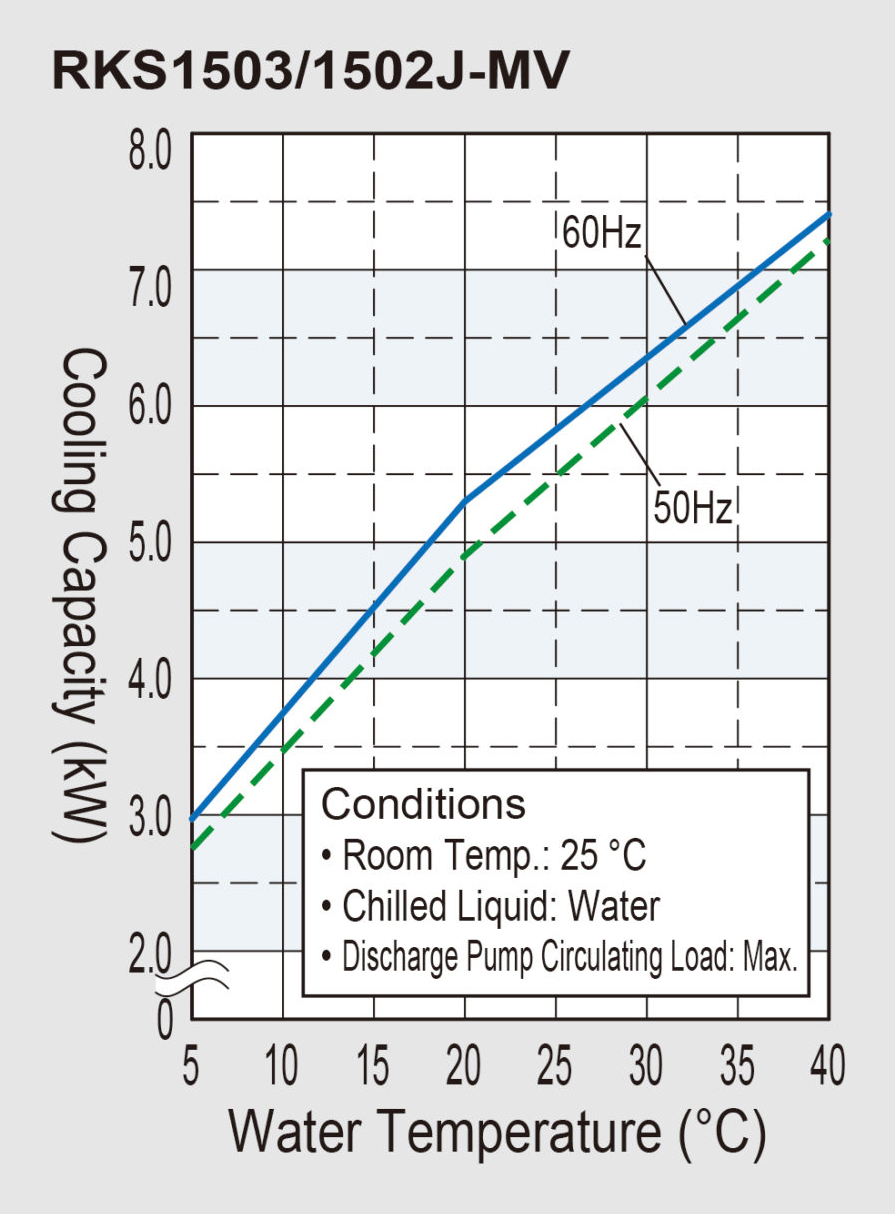

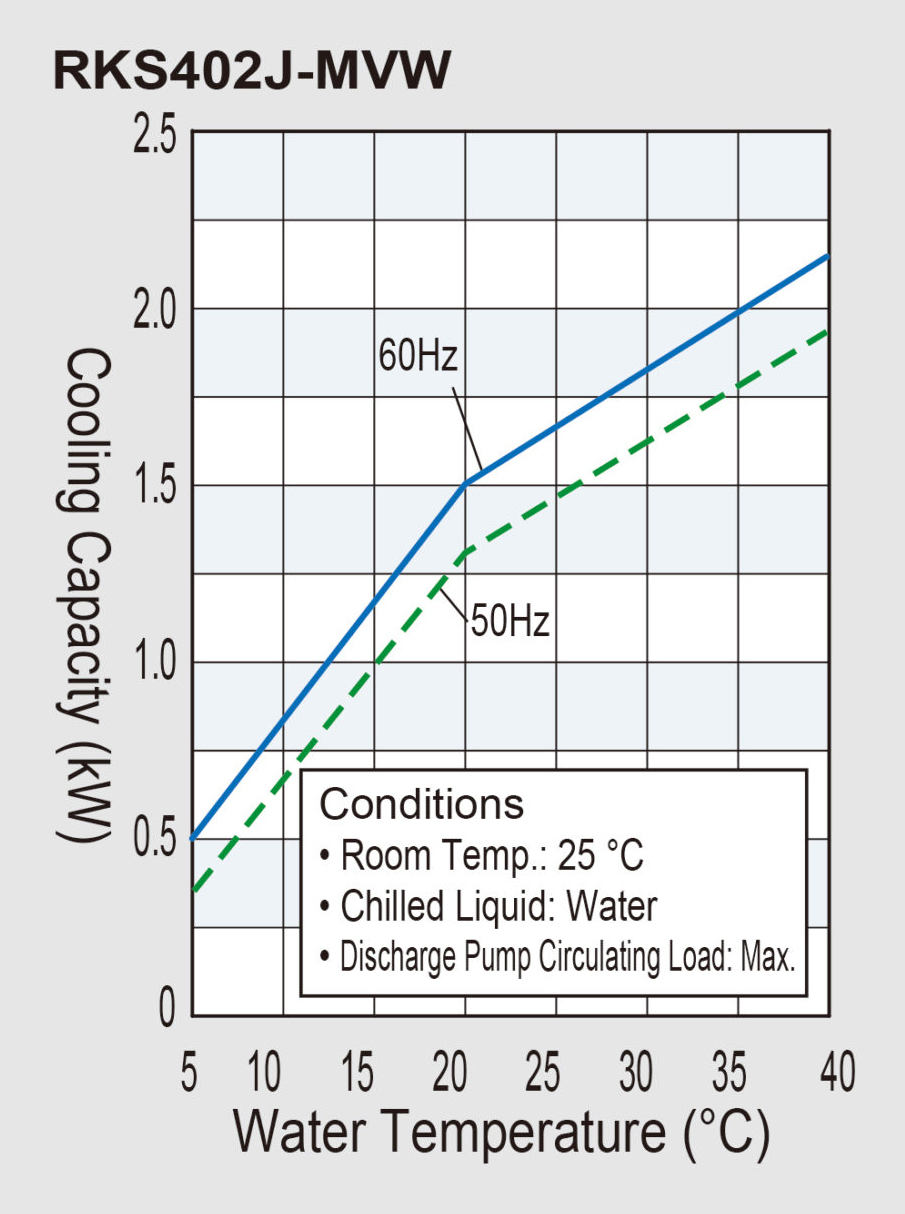

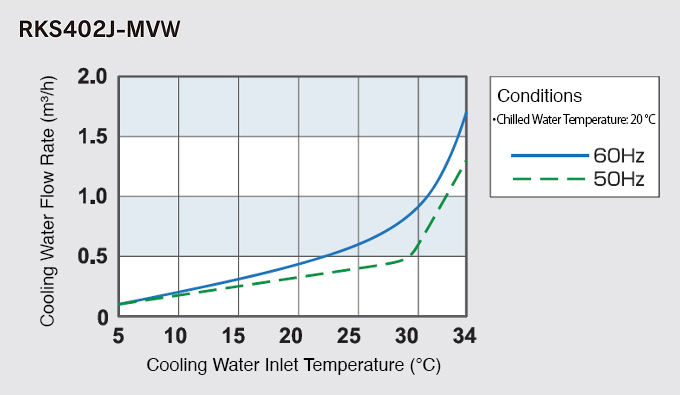

*1 Under the following conditions: Chilled water temp.: 20℃, Ambient temp.: 25℃. Max. discharge pump circulating load. Cooling capacity is at least 95% of listed figures. Heating capacity will change according to operating conditions.

*2 Source voltage phase unbalance should be less than ±3%.

*3 The figure noted is when the equipment is operating at the highest capacity of its normal operating range.

*4 When the current load is continuously within ±10%, and the ambient temperature is stable. However does not include starting times or when the heat-load exceeds the chiller capacity.

*5 Comes standard with a built-in overload protection circuit breaker (NFB).

*6 Operating noise levels are from a position of 1 m in front of the product and at a height of 1 m.

Note 1 : Liquid (chilled water) that can be used are either clean water and a 30 to 40 % ethylene glycol solution. Note that there will be a drop in cooling capacity of 10 % if using a 30 to 40 % ethylene glycol solution. Alternatively, if deionized water is to be used, it should have an electrical conductivity of at least 1μs/cm.

Note 2: Heat output from the unit (in kW) is approx. 1.3 times that of the cooling capacity.

Note 3: Depending on the operating environment, condensation may form on piping inside the product, and temporary leakage of water from the pump mechanical seals may also occur, therefore a drain pan should be installed if required.