Why is Water Cooling Needed for Injection Moding?

Controlled mold cooling with a water chiller stabilizes and improves plastic molding quality.

Mold cooling with chilled water is essential for shorter production cycle times.

Application Examples

・Mold Cooling

・Overheat prevention when mold temperature is heated.

・Hopper Cooling

・Fluid Cooling for LIM (Liquid Injection Molding)

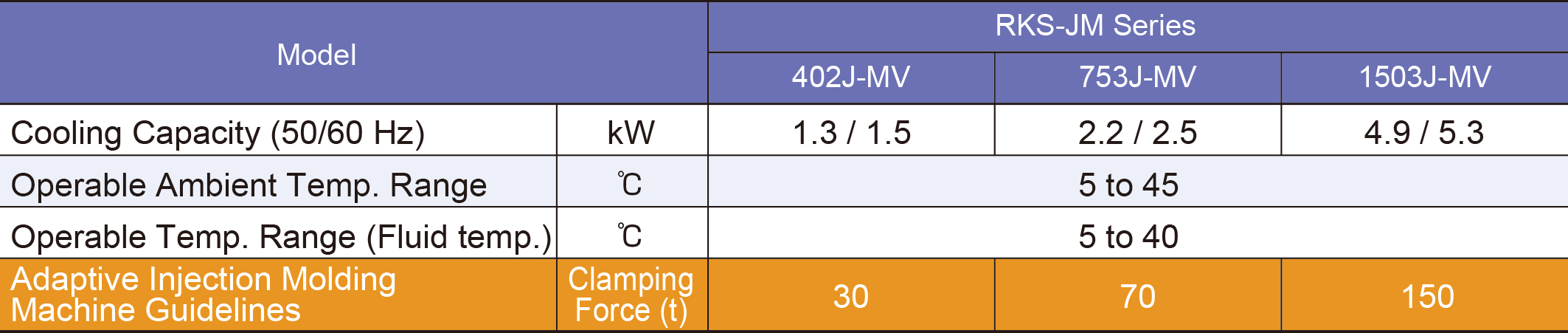

How to Choose the Right Chiller Capacity

The above table shows examples of chiller model selection only.

Cooling capacity (kW) can be calculated by the follwoing formula.

Q = W x J x (C x (T-T' + L x B)) x 1.2

W: Weight, J: Shot Cycle Rate (shots/h), C: Specific Heat (kcal/kg℃), T: Resin Temperature, T': Ejection Temperature

L: Latent Heat, B: Crystalization Rate, Safety Margin: 20%